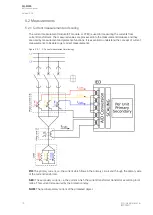

Figure. 5.2.2 - 14. Connections.

The following table presents the initial data of the connection.

Table. 5.2.2 - 23. Initial data.

PPha

hase v

se volta

oltage V

ge VTT

- VT primary: 20 000 V

- VT secondary: 100 V

ZZer

ero sequence v

o sequence volta

oltage V

ge VTT

- U4 VT primary: 20 000 V

- U4 VT secondary: 100 V

- the zero sequence voltage is connected similarly to line-to-neutral voltages (+U0).

- in case wiring is incorrect, all polarities can be individually switched by 180 degrees in the relay.

If the protection is voltage-based, the supervised voltage can be based either on line-to-line voltages or

on line-to-earth voltages. This selection is defined in the "Measured magnitude" of each protection

stage menu separately (

Protection

→

Voltage

→

[protection stage menu]

→

INFO; see the image

below). The number of available protection functions depends on the relay type.

Figure. 5.2.2 - 15. Selecting the measured magnitude.

A

AQ

Q-M255

-M255

Instruction manual

Version: 2.06

32

© Arcteq Relays Ltd

IM00020

Summary of Contents for AQ-M255

Page 1: ...AQ M255 Motor protection IED Instruction manual...

Page 2: ......