The blocking of the function causes an HMI display event and a time-stamped blocking event with

information of the startup current values and its fault type to be issued.

The blocking signal can also be tested in the commissioning phase by a software switch signal when

the relay's testing mode "Enable stage forcing" is activated (

General

→

Device).

The variables the user can set are binary signals from the system. The blocking signal needs to reach

the device minimum of 5 ms before the set operating delay has passed in order for the blocking to

activate in time.

Events and registers

The undercurrent function (abbreviated "NUC" in event block names) generates events and registers

from the status changes in START, TRIP and BLOCKED. The user can select which event messages

are stored in the main event buffer: ON, OFF, or both.

The events triggered by the function are recorded with a time stamp and with process data values.

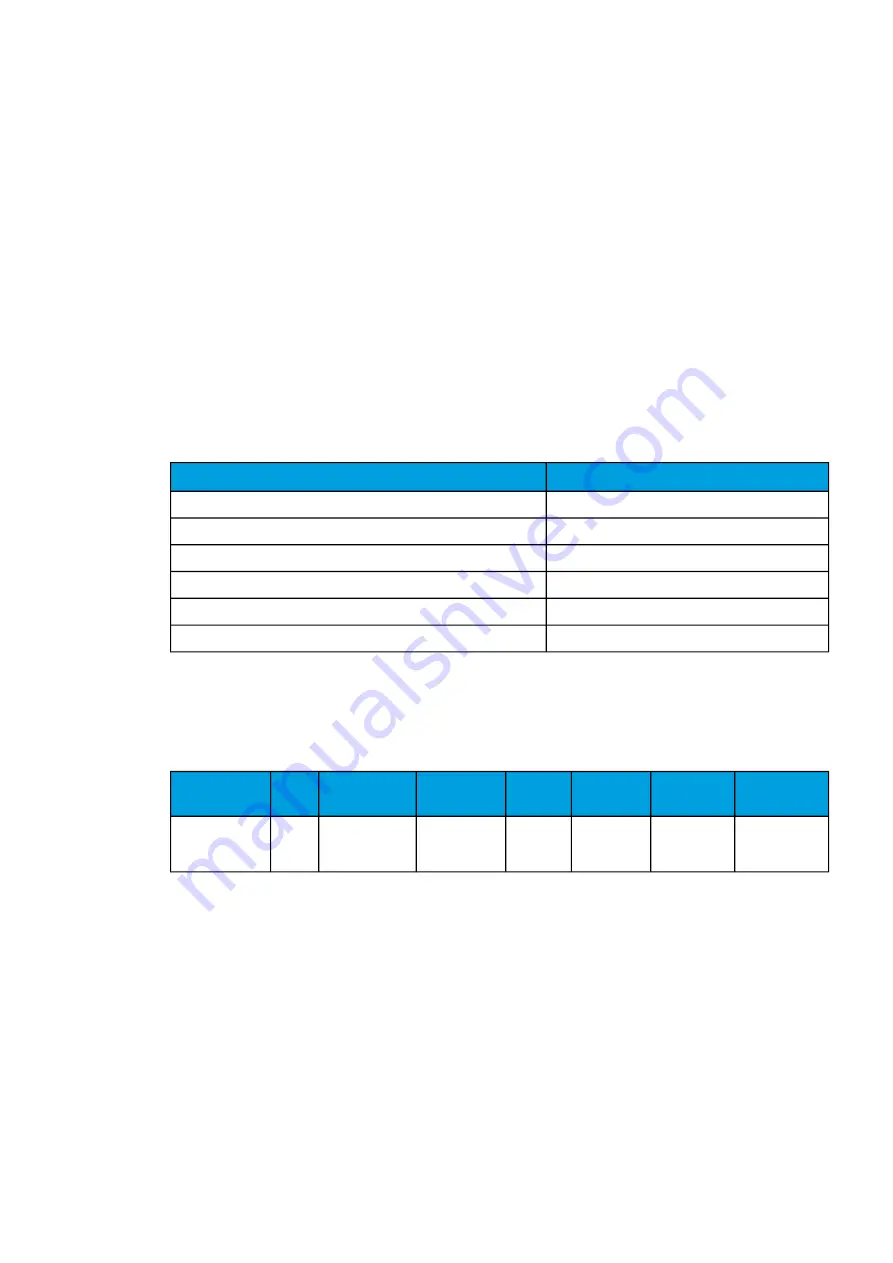

Table. 5.4.20 - 175. Event messages.

Event block name

Event names

NUC1

Start ON

NUC1

Start OFF

NUC1

Trip ON

NUC1

Trip OFF

NUC1

Block ON

NUC1

Block OFF

The function registers its operation into the last twelve (12) time-stamped registers. The register of the

function records the ON event process data for START, TRIP or BLOCKED. The table below

presents the structure of the function's register content.

Table. 5.4.20 - 176. Register content.

Date and time Event

Fault type

Pre-trigger

current

Fault

current

Prefault

current

Trip time

remaining

Used SG

dd.mm.yyyy

hh:mm:ss.mss

Event

name

L1-G…L1-L2-L3

Start/

Trip -20ms

current

Start/Trip

current

Start

-200ms

current

0 ms...1800s

Setting group

1...8 active

5.4.21 Mechanical jam protection (Im>; 51M)

The mechanical jam protection function is used for monitoring motor loading after motor starting. When

a motor-run apparatus jams during its work load, this function can be used to disconnect the motor

from the feeding network in order to avoid further damage to the motor drive. The function is active

only after the motor has started, and it is blocked during motor starting. This is done through

an internal connection of

Motor running and through a Motor starting signal taken from the Motor

status monitoring function. This function operates similarly to the motor starting/locked rotor function

(Ist>; 48/14) although it operates on Definite Time delay and does not work during motor starting. Also,

with the help of a dedicated locked rotor function and mechanical jam protection the user can divide all

possible fault situations based on a quick definition of the fault types in relay events. Additionally, the

Ist> function's setup can be problematic with heavy inertia loads that experience a locked rotor

situation during work load. Having separate functions for start-up and for mechanical jams divides the

situations clearly; for example, the mechanical jam protection can be set to instant operation while the

locked rotor function allows motor starting several tens of seconds.

A

AQ

Q-M257

-M257

Instruction manual

Version: 2.07

210

© Arcteq Relays Ltd

IM00021

Summary of Contents for AQ-M257

Page 1: ...AQ M257 Motor protection IED Instruction manual...

Page 2: ......