140

Removing Valves

NOTE: Index all valves, springs, and cotters to their

original position when removing. When installing, all

valve components should be installed in their origi-

nal position.

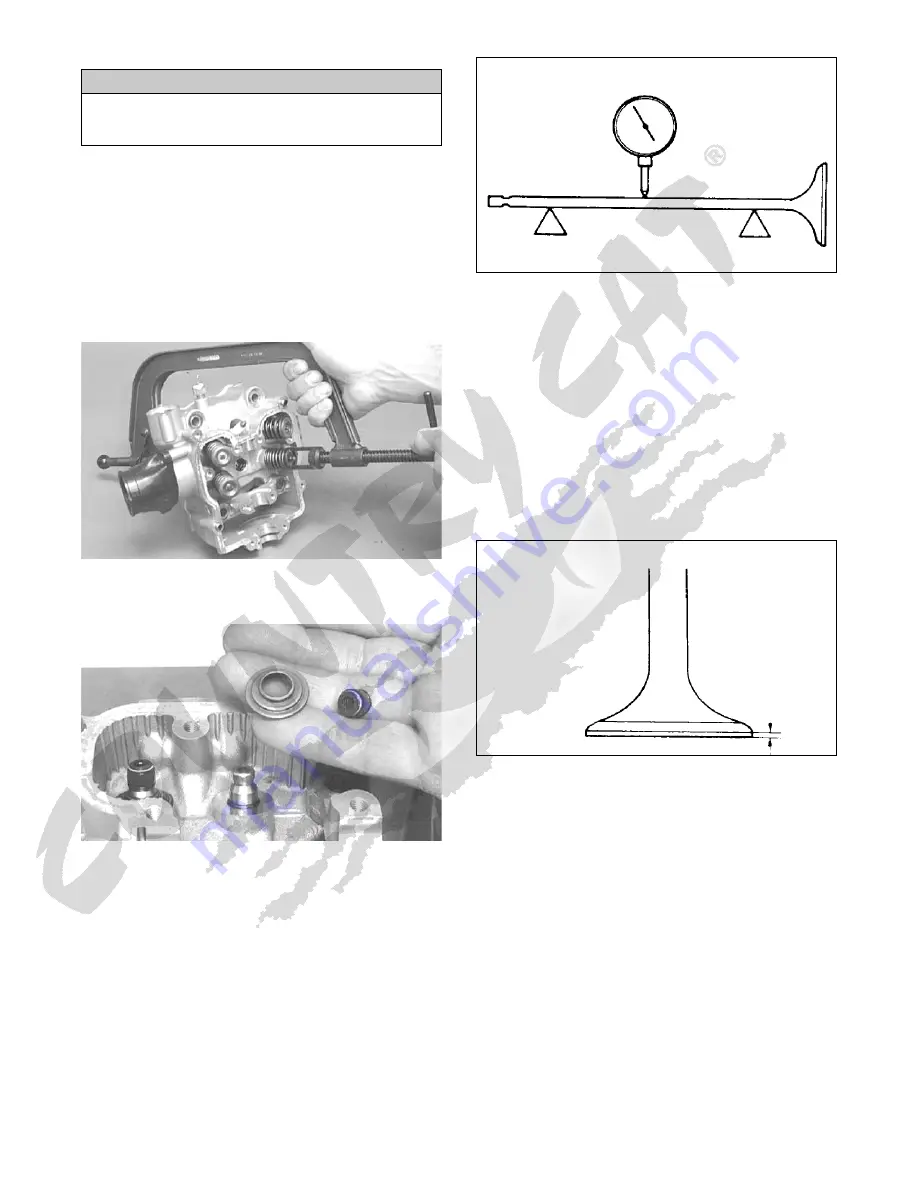

1. Using a valve spring compressor, compress the valve

springs and remove the valve cotters. Account for an

upper spring retainer.

CC132D

2. Remove the valve seal and the lower remaining

spring seat. Discard the valve seal.

CC136D

NOTE: The valve seals must be replaced.

3. Remove the valve springs; then invert the cylinder

head and remove the valves.

Measuring Valve Stem Runout

1. Support each valve stem end with the V Blocks; then

check the valve stem runout using a dial indicator.

ATV-1082

2. Maximum runout must not exceed specifications.

Measuring Valve Stem

Outside Diameter

1. Using a micrometer, measure the valve stem outside

diameter.

2. Acceptable diameter ranges must be within specifi-

cations.

Measuring Valve Face/Seat Width

1. Using a micrometer, measure the width of the valve

face.

ATV-1004

2. Acceptable widths must be within specifications.

Measuring Valve Face Radial Runout

1. Mount a dial indicator on the surface plate; then

place the valve stem on a set of V blocks.

2. Position the dial indicator contact point on the out-

side edge of the valve face; then zero the indicator.

CAUTION

Water or parts-cleaning solvent must be used in con-

junction with the wet-or-dry sandpaper or damage to

the sealing surface may result.