179

GZ342

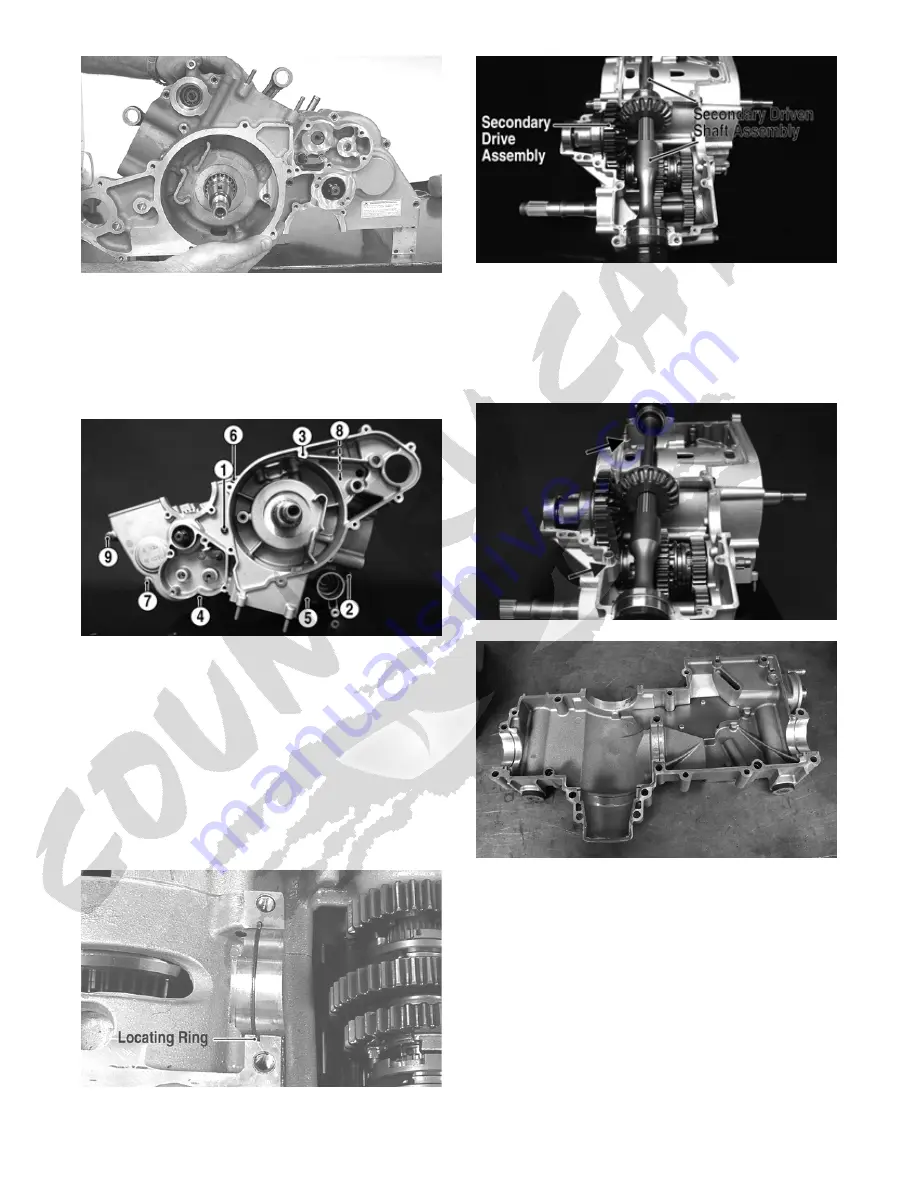

5. Tighten the 6 mm cap screws to 10 ft-lb and the 8

mm cap screws to 21 ft-lb using the pattern shown

and turning the shafts frequently to ensure there is no

binding.

NOTE: Rotate the shafts back and forth to ensure

no binding or sticking occurs.

GZ457A

NOTE: Cap screw number eight (8) is installed from

the right side.

NOTE: If the secondary drive/driven assemblies

have been disassembled, refer to Servicing Center

Crankcase Components for proper gear tooth contact

and backlash.

6. Install the locating ring in the crankcase assembly;

then install the secondary driven shaft assembly and

secondary drive assembly making sure the locating

ring and bearing engage correctly.

GZ269A

GZ448A

7. Make sure the locating pins on the front and rear

bearings are correctly seated in the crankcase.

8. Install two alignment pins into the upper crankcase

assembly; then apply a thin bead of Loctite #5900 or

suitable substitute sealant to the lower crankcase

cover.

GZ452A

GZ451

9. Carefully place the lower crankcase cover onto the

joined crankcase halves; then secure with the cap

screws. Tighten the 6 mm cap screws to 10 ft-lb and

the 8 mm cap screws to 21 ft-lb.