51

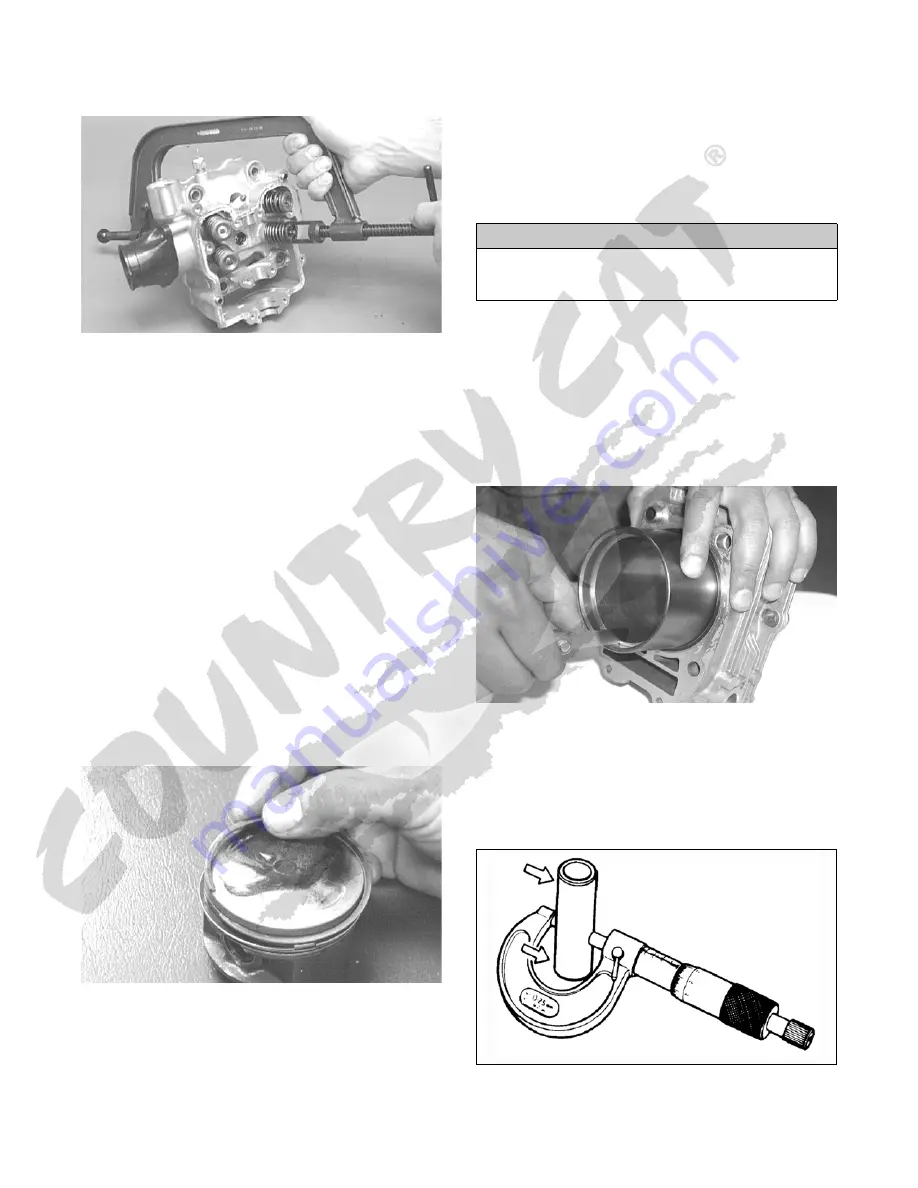

4. Place a spring retainer over the valve springs; then

using the valve spring compressor, compress the

valve springs and install the valve keepers.

CC132D

PISTON ASSEMBLY

NOTE: Whenever a piston, rings, or pin are out of

tolerance, they must be replaced.

Cleaning/Inspecting Piston

1. Using a non-metallic carbon removal tool, remove

any carbon buildup from the top of the piston.

2. Inspect the piston for cracks in the piston pin, boss,

top, and skirt areas.

3. Inspect the piston for seizure marks or scuffing. If

piston is scored or galled, replace it with a new one.

4. Inspect the perimeter of each piston for signs of

“blowby” indicated by dark discoloration. “Blowby”

is caused by worn piston rings, excessive carbon in

ring grooves, or an out-of-round cylinder.

Removing Piston Rings

1. Starting with the top ring, slide one end of the ring

out of the ring-groove.

CC400D

2. Remove each ring by working it toward the top of

the piston while rotating it out of the groove.

NOTE: When installing new rings, install as a

complete set only.

Cleaning/Inspecting Piston Ring

Grooves

1. Take an old piston ring and snap it into two pieces;

then grind the end of the old ring to a 45° angle and

to a sharp edge.

2. Using the sharpened ring as a tool, clean carbon from

the ring grooves. Be sure to position the ring with its

tapered side up.

Measuring Piston-Ring End Gap

(Installed)

1. Place each piston ring in the wear portion of the cyl-

inder. Use the piston to position each ring squarely in

the cylinder.

2. Using a feeler gauge, measure each piston-ring end

gap. Acceptable ring end gap must not exceed speci-

fications.

CC995

Measuring Piston Pin, Connecting

Rod Small End, and Piston-Pin Bore

1. Measure the piston pin outside diameter at each end

and in the center. If measurement does not meet

specifications, the piston pin must be replaced.

ATV-1070

CAUTION

Improper cleaning of the ring grooves by the use of the

wrong type of ring groove cleaner will result in severe

damage to the piston.