5-7

5

NOTE: The coil is located to the right of the

engine and may be accessed from behind the

right-side seat with the cargo box raised.

2. Connect the red tester lead to the orange wire and

the black tester lead to the blue/white wire.

3. Turn the ignition switch to the ON position. The

meter must show battery voltage.

EFI Sensors/

Components

(XTX)

CRANKSHAFT POSITION (CKP)

SENSOR

To test the CKP sensor, see Stator Coil/Crankshaft

Position (CKP) Sensor (XTX) in this section.

MANIFOLD ABSOLUTE PRESSURE

(MAP) SENSOR

1. Disconnect the MAP connector from the pressure

sensor located on the throttle body.

2. Select DC Voltage on the tester and turn the igni-

tion switch to the ON position.

3. Connect the black tester lead to the black/green

wire and the red tester lead to the brown/white

wire. The meter should read 4.5-5.5 DC volts. If

the meter does not read as specified, check the

ECU connector or wiring.

4. Connect the MAP to the harness; then using Maxi-

Clips, connect the red tester lead to the

brown/white wire and the black tester lead to the

black/green wire. With the engine running at idle

speed, the meter should read approximately 1.5

DC volts.

NOTE: If the meter does not read as specified,

replace the sensor.

Speed Sensor

(XT/XTX)

NOTE: Prior to testing the speed sensor, inspect

the three-wire connector on the speed sensor for

contamination, broken pins, and/or corrosion.

1. Set the meter selector to the DC Voltage position.

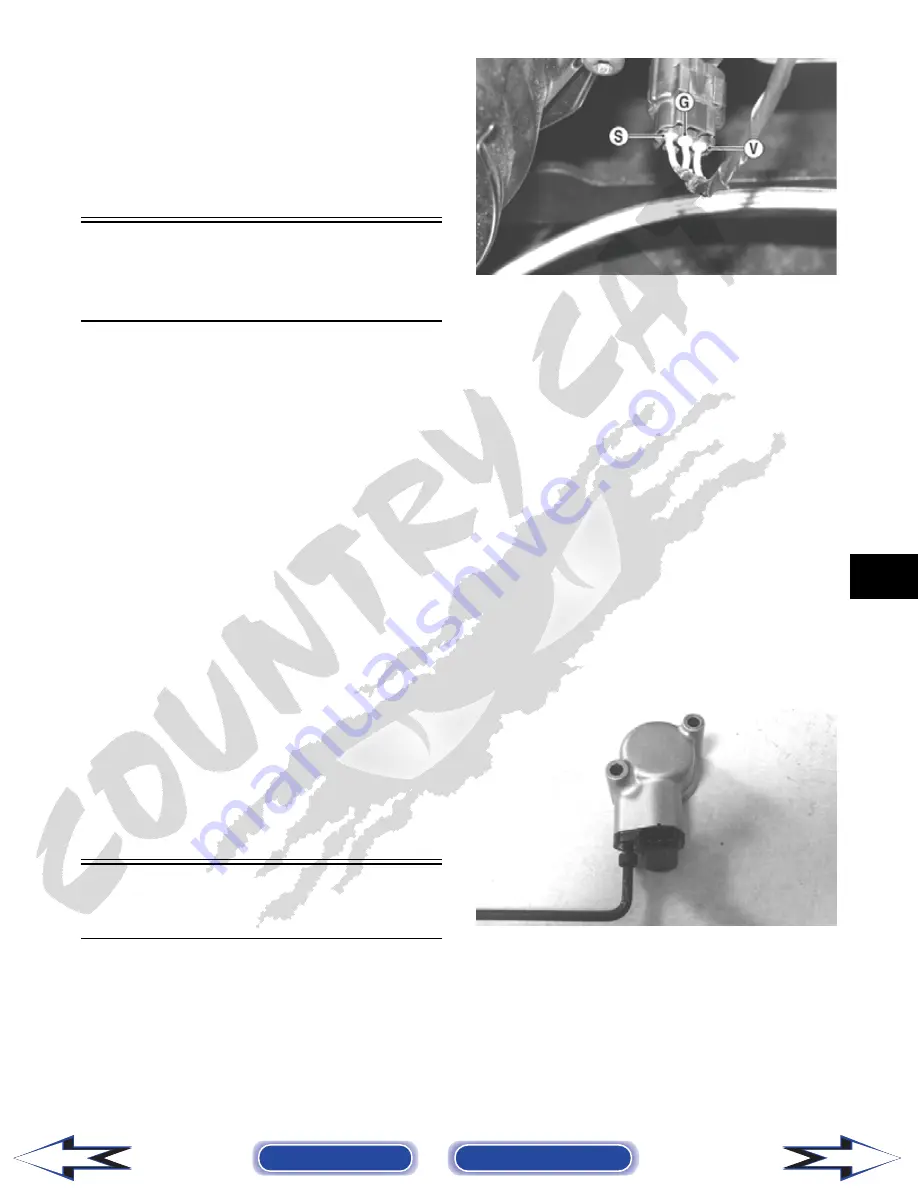

2. With appropriate needle adapters on the meter

leads, connect the red tester lead to the voltage

lead (V); then connect the black tester lead to the

ground lead (G).

PR279A

3. Turn the ignition switch to the ON position.

4. The meter must show approximately 6 DC volts.

5. Leave the black tester lead connected; then con-

nect the red tester lead to the signal lead pin (S).

6. Slowly move the vehicle forward or backward; the

meter must show 0 and approximately 6 DC volts

alternately.

NOTE: If the sensor tests are within specifica-

tions, the speedometer must be replaced (see Sec-

tion 9).

To replace a speed sensor, use the following proce-

dure.

1. Disconnect the three-wire connector from the

speed sensor harness or from the speed sensor;

then remove the Allen-head cap screw securing

the sensor to the sensor housing.

2. Remove the sensor from the sensor housing

accounting for an O-ring.

CD070

3. Install the new speed sensor into the housing with

new O-ring lightly coated with multi-purpose

grease; then secure the sensor with the Allen-head

cap screw (threads coated with blue Loctite #242).

Tighten securely.

Back to TOC

Back to Section TOC

Next

Back