6-12

CF266A

CF267A

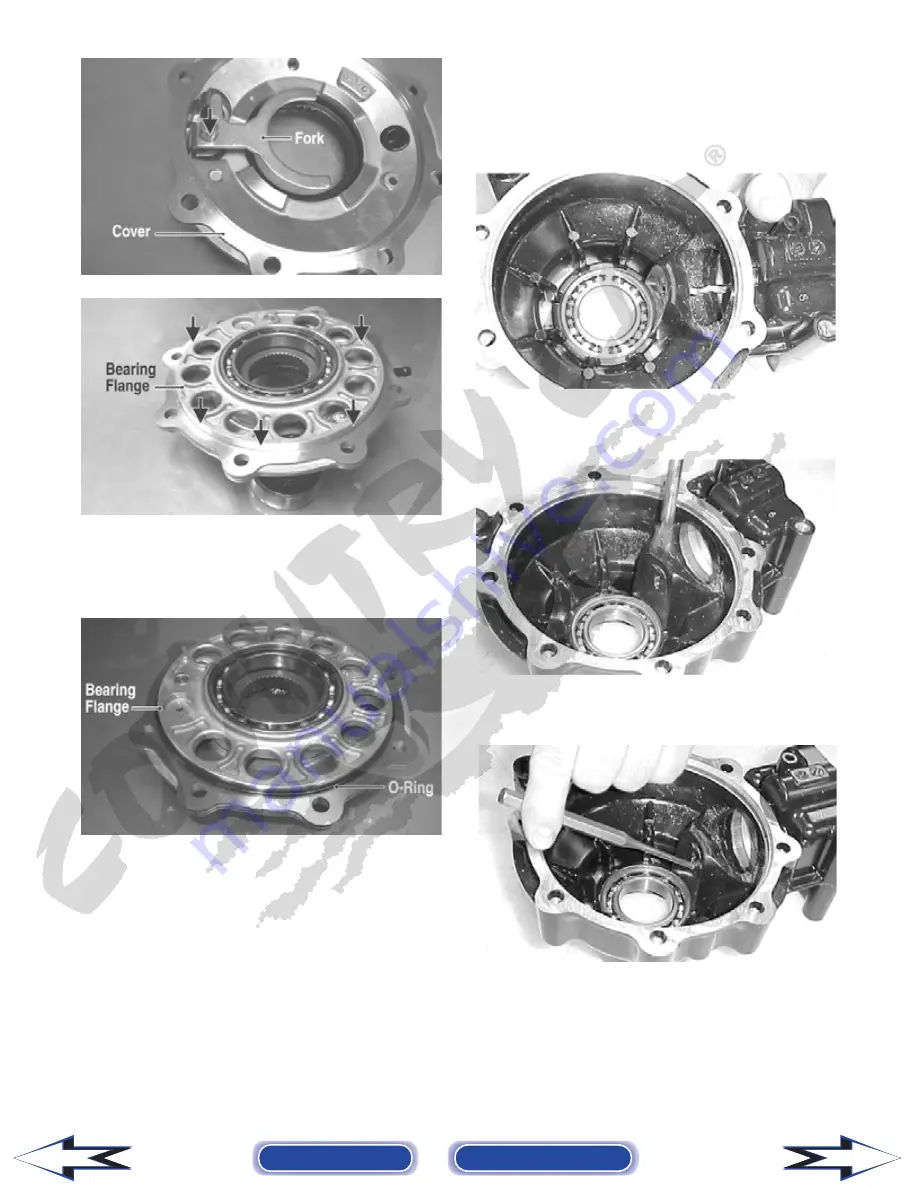

10. Apply a liberal coat of grease to the O-ring; then

install it on the assembled cover assembly making

sure to seat the O-ring completely down around

the circumference of the bearing flange.

CF275A

11. Making sure the O-ring is properly positioned on

the gear case cover assembly, install the cover with

existing hardware. Account for the ID tag. Tighten

the cap screws to 23 ft-lb.

NOTE: Grease can be applied to the O-ring for

ease of assembling.

NOTE: If a new gear case housing is being

installed, tighten the cap screws to 28 ft-lb.

Removing Needle Bearing

NOTE: Removing the needle bearing is rarely

necessary. Avoid removing the needle bearing

unless the bearing is clearly damaged.

NOTE: This procedure can be performed on a

rear gear case (Prowler/XT)/rear differential (XTX).

1. Place a 1/4 in. drill bit on the inside surface of the

needle bearing (against the bottom side); then drill

through the pinion shaft needle bearing housing.

CC885

2. Using a propane torch, heat the area surrounding

the needle bearing to soften the Loctite.

CC886

3. Using a flat-nosed punch, drive the bearing out of

the housing.

CC887

Installing Needle Bearing

1. Apply red Loctite #271 to the outside of a new

bearing; then place the new bearing into the hous-

ing.

Back to TOC

Back to Section TOC

Next

Back