4-18

4. Start the engine to verify proper engine operation;

then shut off the engine and install the right-side

seat-base, center console, and seats making sure

the seats lock securely into place.

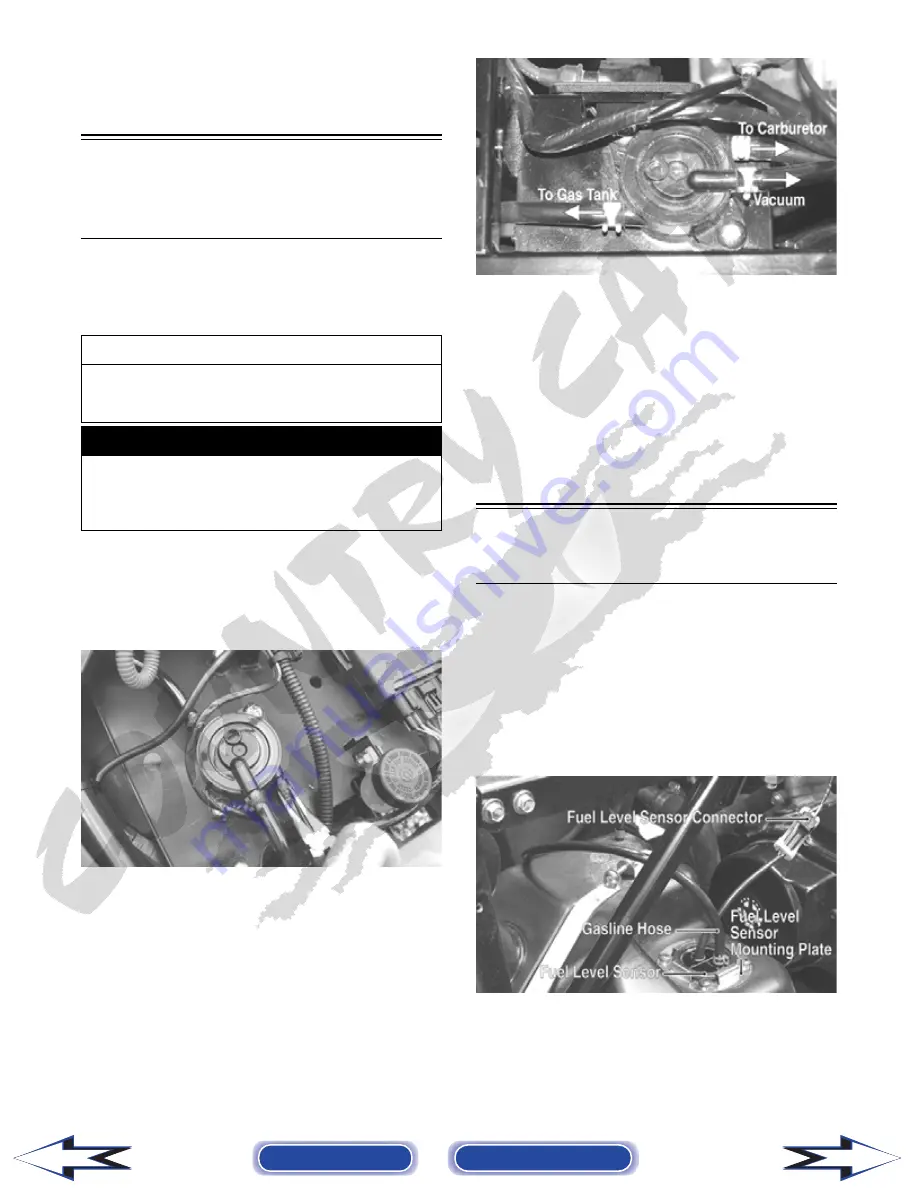

Vacuum Pulse

Fuel Pump

(Prowler/XT)

NOTE: The vacuum pulse fuel pump is a nonser-

viceable assembly. If the pump fails, it must be

replaced.

TESTING

1. Disconnect the fuel pump/carburetor hose at the

fuel pump; then connect a hose and suitable pres-

sure gauge to the fuel pump output fitting.

CD815

2. Start the engine. Fuel pump pressure should show

0.036-0.084 kg/cm

2

(0.5-1.2 psi).

REMOVING

1. Remove the right-side seat-base; then remove the

three clamps securing the gas hoses and vacuum

hose and disconnect the hoses.

PR280A

2. Remove the two machine screws and flange nuts

securing the fuel pump to the electrical tray; then

remove the pump.

INSTALLING

1. Place the fuel pump into position on the electrical

tray; then secure with the machine screws and

flange nuts. Tighten securely.

2. Connect two gas hoses and one vacuum hose; then

secure with the clamps.

Fuel Level Sensor

(XT)

REMOVING

1. Remove the seats and the center console; then

remove the right-side seat-base.

2. Remove the gasline hose and disconnect the fuel

level sensor connector; then remove four

torx-head machine screws and the fuel level sensor

mounting plate.

PR166C

3. Remove the fuel level sensor from the gas tank.

Account for a seal.

AT THIS POINT

Prior to removing the vacuum pulse fuel pump, the

following test should be performed to determine that

removal is necessary.

! WARNING

Whenever any maintenance or inspection is made

on the fuel system during which there may be fuel

leakage, there should be no welding, smoking, open

flames, etc., in the area.

Back to TOC

Back to Section TOC

Next

Back