3-13

3

Servicing Valves/Valve

Guides/Valve Seats

If valves, valve guides, or valve seats require servicing

or replacement, Arctic Cat recommends that the com-

ponents be taken to a qualified machine shop for ser-

vicing.

Measuring Rocker Arm

(Inside Diameter)

1. Using a dial calipers, measure the inside diameter

of the rocker arm.

2. Acceptable inside diameter must not exceed speci-

fication.

Measuring Rocker Arm Shaft

(Outside Diameter)

1. Using a micrometer, measure the outside diameter

of the rocker arm shaft.

2. Acceptable outside diameter must be at or above

specification.

Installing Valves

1. Apply grease to the inside surface of the valve

seals; then place a lower spring seat and valve

guide seal over each valve guide.

CC144D

2. Insert each valve into its original location.

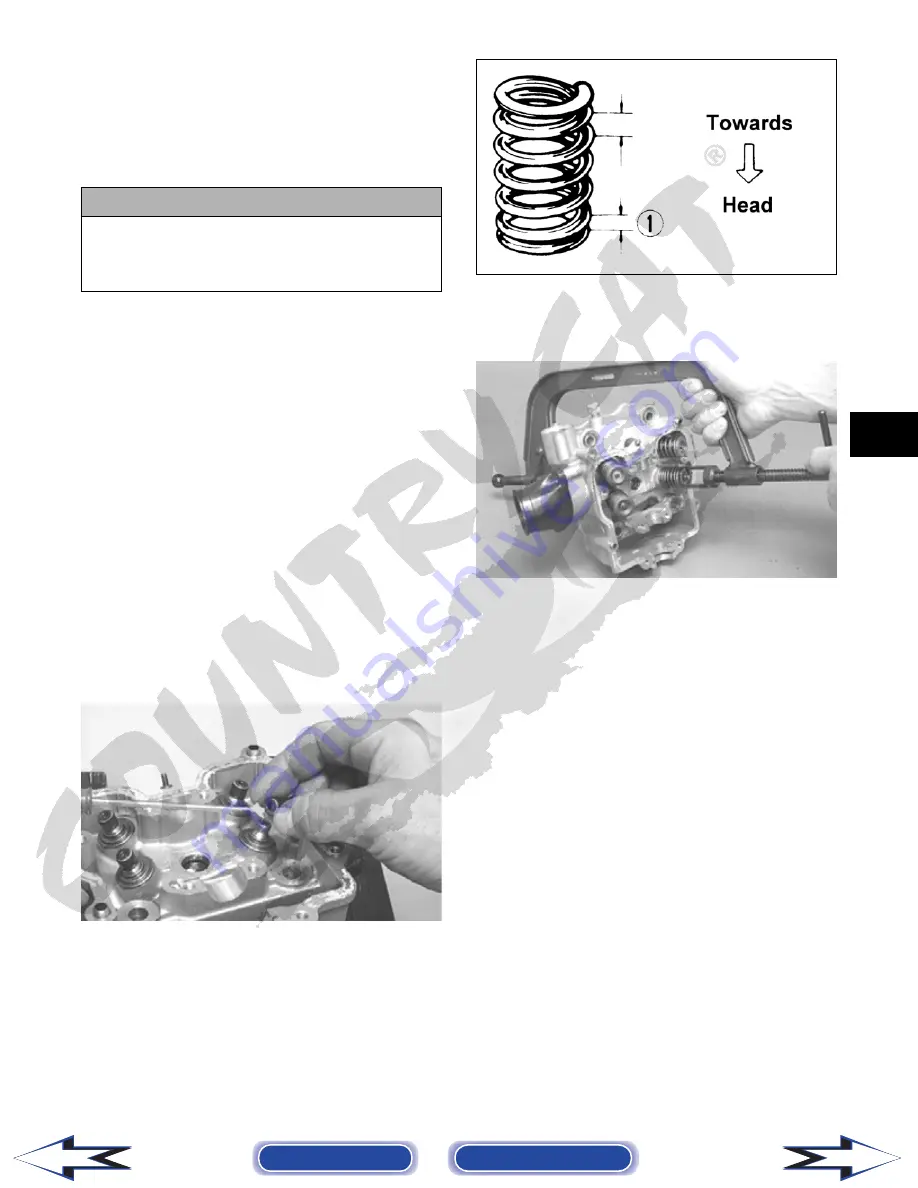

3. Install the valve springs with the painted end of the

spring facing away from the cylinder head.

NOTE: If the paint is not visible, install the ends

of the springs with the closest wound coils toward

the head.

ATV-1011A

4. Place a spring retainer over the valve springs; then

using the valve spring compressor, compress the

valve springs and install the valve cotters.

CC132D

PISTON ASSEMBLY

NOTE: Whenever a piston, rings, or pin are out of

tolerance, they must be replaced.

Cleaning/Inspecting Piston

1. Using a non-metallic carbon removal tool, remove

any carbon buildup from the dome of the piston.

2. Inspect the piston for cracks in the piston pin,

dome, and skirt areas.

3. Inspect the piston for seizure marks or scuffing.

Repair with #400 grit wet-or-dry sandpaper and

water or honing oil.

NOTE: If scuffing or seizure marks are too deep

to correct with the sandpaper, replace the piston.

4. Inspect the perimeter of each piston for signs of

excessive “blowby.” Excessive “blowby” indicates

worn piston rings or an out-of-round cylinder.

Removing Piston Rings

1. Starting with the top ring, slide one end of the ring

out of the ring-groove.

! CAUTION

If valves are discolored or pitted or if the seating

surface is worn, the valve must be replaced. Do not

attempt to grind the valves or severe engine damage

may occur.

Back to TOC

Back to Section TOC

Next

Back