3-33

3

Cleaning and Inspecting Cylinder

Head/Valves

1. Thoroughly clean the cylinder head in a non-caus-

tic solvent; then dry with compressed air.

2. Using a high-quality straight edge and feeler

gauges, check the head for warpage; then holding

the straight edge against the head, measure any

warpage with the feeler gauge. Check cor-

ner-to-corner, side-to-side, and end-to-end.

DE302

NOTE: If cylinder head warpage is present, the

cylinder head must be planed by a qualified

machine shop. Pre-combustion chambers must be

removed to plane the head.

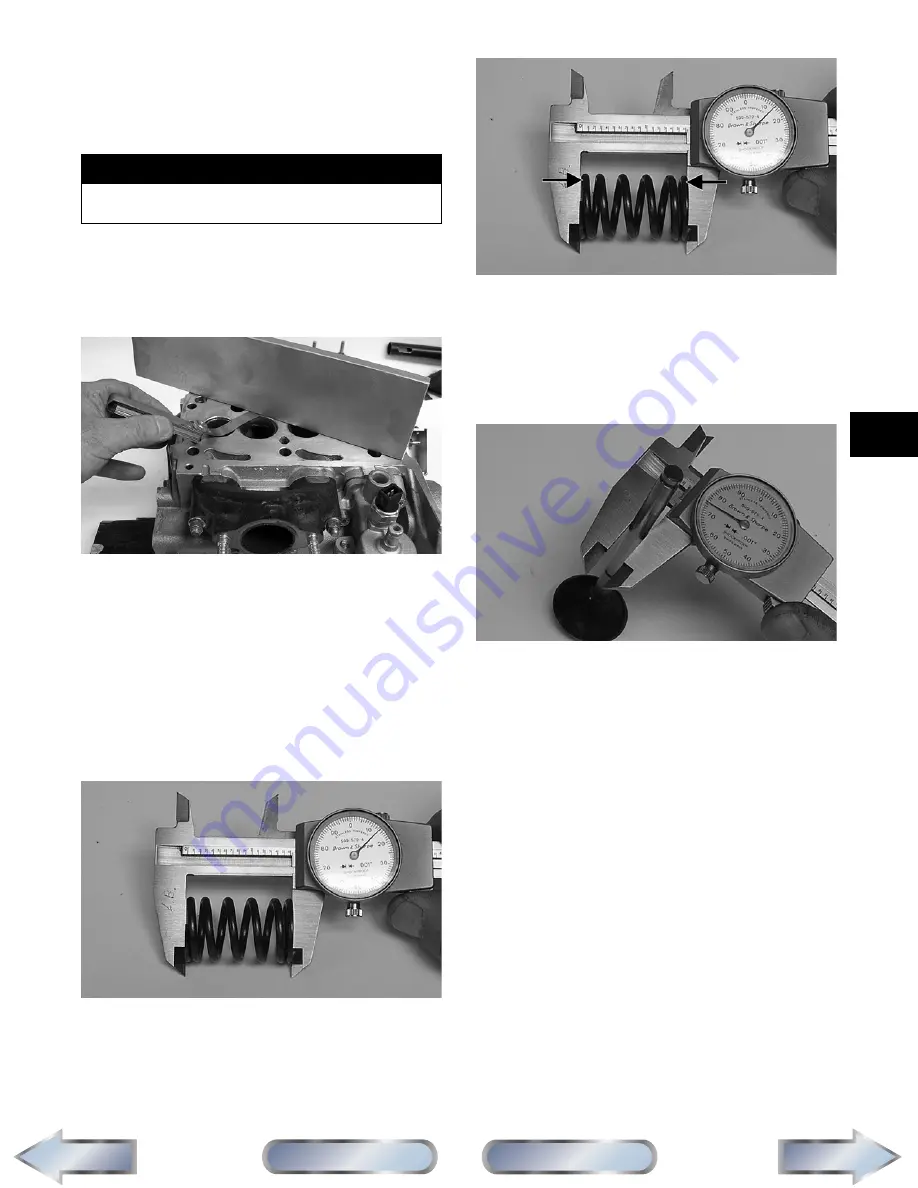

3. Inspect the valve springs for surface cracks and

fractures.

4. Using a calipers, measure the free-length of the

valve springs. The measurement must be equal to

or greater than minimum specifications.

DE318

5. Check that the spring ends are parallel. A caliper

may be used to check parallelism of spring ends.

DE318A

6. Clean valve faces, valve seats, and valve stems.

DO NOT use a wire brush on valve stems.

7. Using a suitable calipers or outside micrometer,

measure the valve stem. If valve stem measures

less than minimum specifications, the valve must

be replaced.

DE319

8. Measure the valve guide inside diameter using a

suitable micrometer or bore gauge. If measure-

ment is greater than specified, the valve guide

must be replaced.

9. Check the valve seats for evidence of discolor-

ation, cracks, or loose fit in cylinder head as well

as clean, even contact area. Replace any valve

seats that show evidence of excessive wear or

damage.

10. Check the cylinder head for cracks, loose rocker

arm studs, or loose injector hold-down studs. If

cylinder head is cracked, it must be replaced.

! WARNING

Always wear safety glasses when working with com-

pressed air.

Next

Back

Section

Table of Contents

Manual

Table of Contents

FOR ARCTIC CAT ATV DISCOUNT PARTS CALL 606-678-9623 OR 606-561-4983

www.mymowerparts.com