56

3. Inspect the oil pressure relief valve for evidence of

metal chips or contamination. Do not disassemble

the valve.

FI588

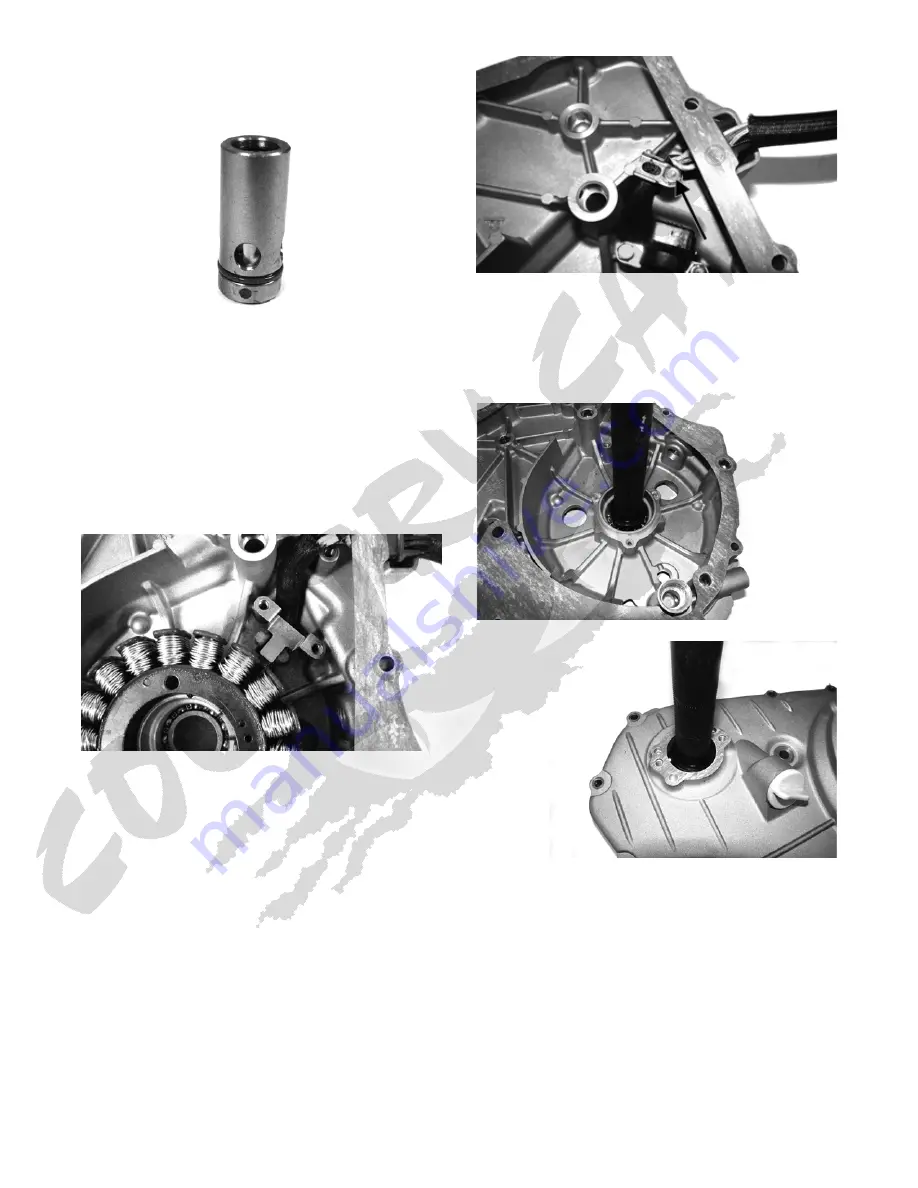

REPLACING STATOR/CRANKSHAFT

POSITION SENSOR

1. Remove the three cap screws securing the stator coil,

two cap screws securing the crankshaft position sen-

sor, and one cap screw from the harness hold-down.

2. Lift the rubber grommet out of the housing; then

remove the stator coil/crankshaft position sensor.

Account for and note the position of the harness

hold-down under the crankshaft position sensor.

FI590

3. Install the new stator assembly and secure with three

cap screws using a drop of red Loctite #271 on each.

Tighten to 8 ft-lb.

4. Place the stator wire harness hold-down into posi-

tion; then install the crankshaft position sensor and

secure with two cap screws. Tighten securely.

5. Install the upper cable hold-down and secure with a

cap screw. Tighten securely.

FI595A

REPLACING MAGNETO COVER

BEARINGS

1. Using a suitable press and proper support, press the

bearing from the housing as indicated (one from out-

side and one from inside).

FI593

FI594

2. Clean the bearing bores in the housing and inspect

closely for cracks or shiny areas indicating bearing

movement. Replace the housing if any of the above

are evident.

3. With a drop of red Loctite #271 around the bearing

bore, press a new bearing into the magneto cover

until the bearing is firmly seated in the bearing bore.