74

ROV374

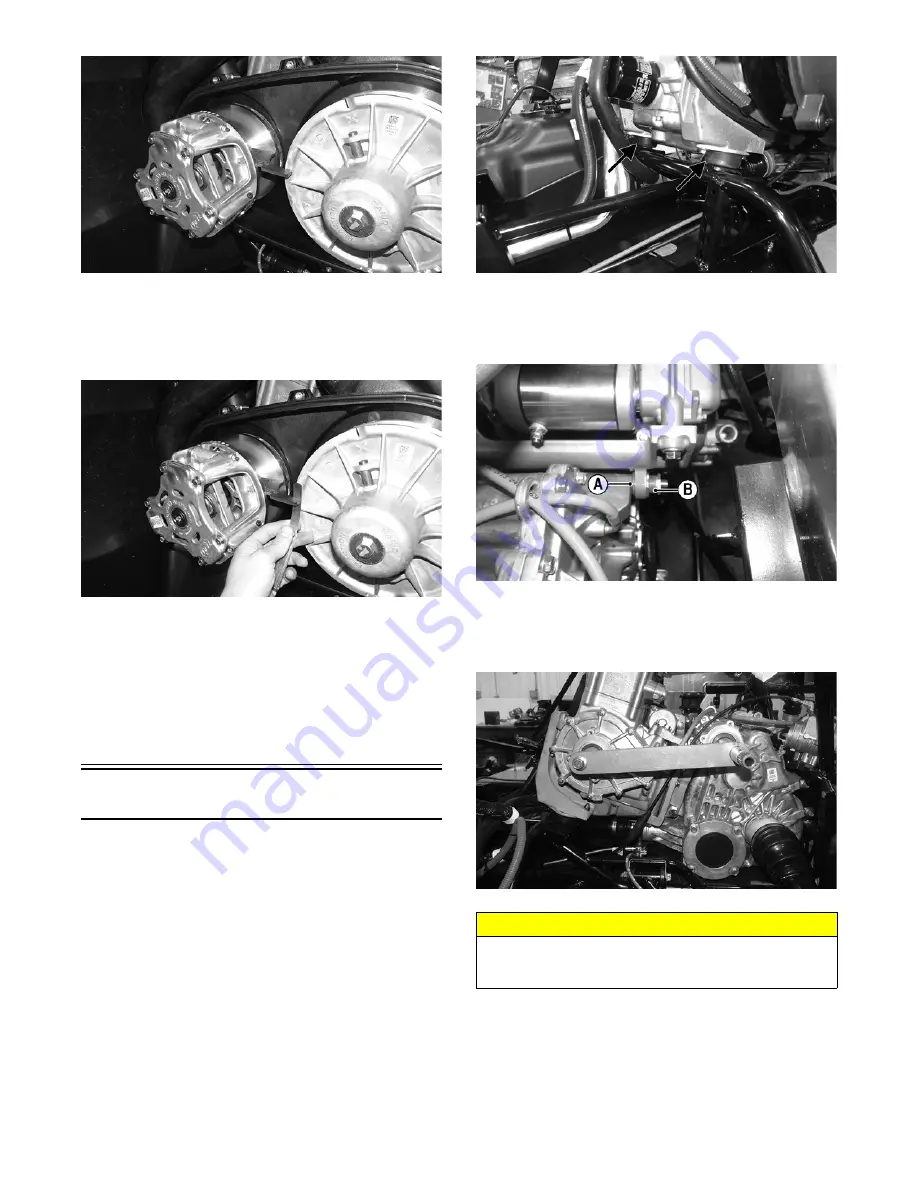

2. The bar should just clear the outside edge of the sta-

tionary sheave of the driven clutch with a maximum

of 0.76 mm (0.030 in.) clearance. If the bar will not

clear the outside edge or clearance is more than the

specified amount, the alignment must be corrected.

ROV375

NOTE: If alignment must be corrected, add or

remove the appropriate alignment shim (p/n 1423-189

– 1.02 mm) or (p/n 1423-219 – 0.51 mm).

3. Repeat steps 1 and 2 as required until correct align-

ment is achieved.

NOTE: To install left-side components, see Engine –

Installing Engine.

Installing Engine

NOTE: The driveshaft must be secured to the tran-

saxle before the engine is installed.

NOTE: If removed, install the engine/transaxle

mounting brackets to the rear of the engine; then

install the front rubber engine mounts to the front

engine brackets. Secure the front engine brackets to

the front of the crankcase assembly.

1. Using a proper lifting device, install the front engine

mount studs into the frame. In the chassis, install the

new lock nuts but do not tighten at this time.

WT515A

2. Align and install the cap screws securing the engine

to the transaxle. Account for a spacing washer (A).

Apply anti-seize compound to the threads of the

adjuster nut (B) but do not tighten at this time.

WT474A

3. Using Drive and Driven Clutch Center to Center

Tool, install the tool over the output shaft of the tran-

saxle and using the cap screw provided and secure it

to the crankshaft.

WT475

4. With the jam nut loosened towards the shoulder of

the adjuster nut, tighten the adjuster nut (A) to 10

ft-lb and then the jam nut (B) to 15 ft-lb.

CAUTION

Care should be taken to install the tool over the output

shaft and slide the tool evenly towards the crankshaft to

avoid damaging the shaft.