38

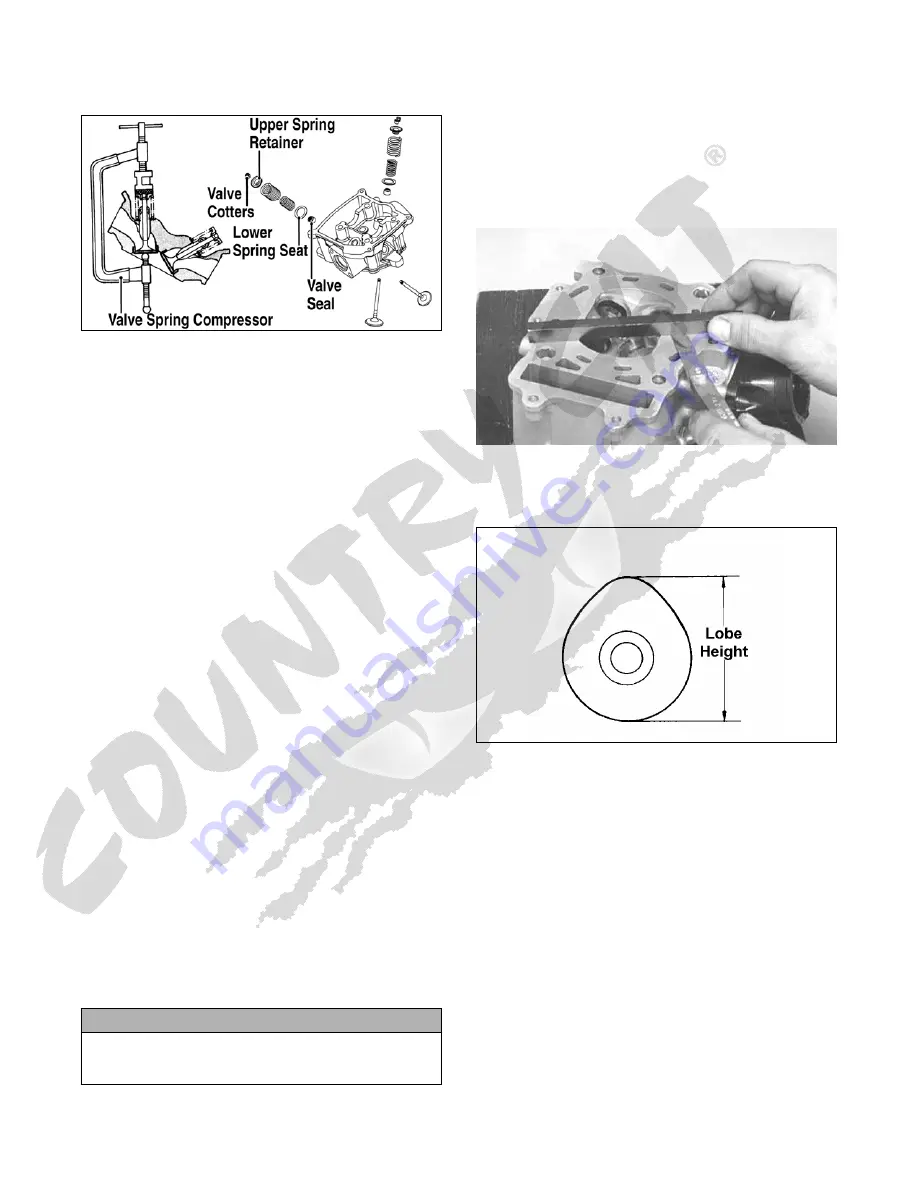

1. Using a valve spring compressor, compress the valve

springs and remove the valve cotters. Account for an

upper spring retainer.

KM717A

2. Remove the valve seal, valve springs, and the lower

remaining spring seat. Discard the valve seal.

NOTE: The valve seals must be replaced.

3. Invert the cylinder head and remove the valves.

Measuring Valve Stem/Valve Guide

Clearance

1. Using a micrometer, measure the valve stem outside

diameter; then using a suitable snap gauge and

micrometer, measure the valve guide inside diameter.

2. Acceptable clearance must be within specifications.

Inspecting Valve Face

Inspect the valve face for pitting, grooving, or discolor-

ation. Replace any valve that is damaged.

CYLINDER HEAD ASSEMBLY

NOTE: If the cylinder head cannot be trued, it must

be replaced.

Cleaning/Inspecting Cylinder Head

1. Using a non-metallic carbon removal tool, remove

any carbon build-up from the combustion chamber

making sure not to nick, scrape, or damage the com-

bustion chamber or the sealing surface.

2. Inspect the spark plug hole for any damaged threads.

Repair damaged threads using a “heli-coil” insert.

3. Place the cylinder head on the surface plate covered

with #400 grit wet-or-dry sandpaper. Using light

pressure, move the cylinder head in a figure eight

motion. Inspect the sealing surface for any indication

of high spots. A high spot can be noted by a bright

metallic finish. Correct any high spots before assem-

bly by continuing to move the cylinder head in a fig-

ure eight motion until a uniform bright metallic

finish is attained.

Measuring Cylinder Head

Distortion

1. Remove any carbon buildup in the combustion

chamber.

2. Lay a straightedge across the cylinder head; then

using a feeler gauge, check the distortion factor

between the head and the straightedge.

3. Maximum distortion must not exceed specifications.

CC141D

Measuring Camshaft Lobe Height

1. Using a calipers, measure each cam lobe height.

ATV1013A

2. The lobe heights must not be less than minimum

specifications.

Inspecting Camshaft Bearing

Journal

1. Inspect the bearing journal for scoring, seizure

marks, or pitting.

2. If excessive scoring, seizure marks, or pitting is

found, the cylinder head assembly must be replaced.

Measuring Rocker Arm/

Shaft Clearance

1. Using a dial calipers, measure the inside diameter of

the rocker arm; then measure the outside diameter of

the rocker arm shaft.

2. Acceptable clearance must not exceed specifications.

CAUTION

Water or parts-cleaning solvent must be used in con-

junction with the wet-or-dry sandpaper or damage to

the sealing surface may result.