5

Crankshaft Runout/

Repair Specifications

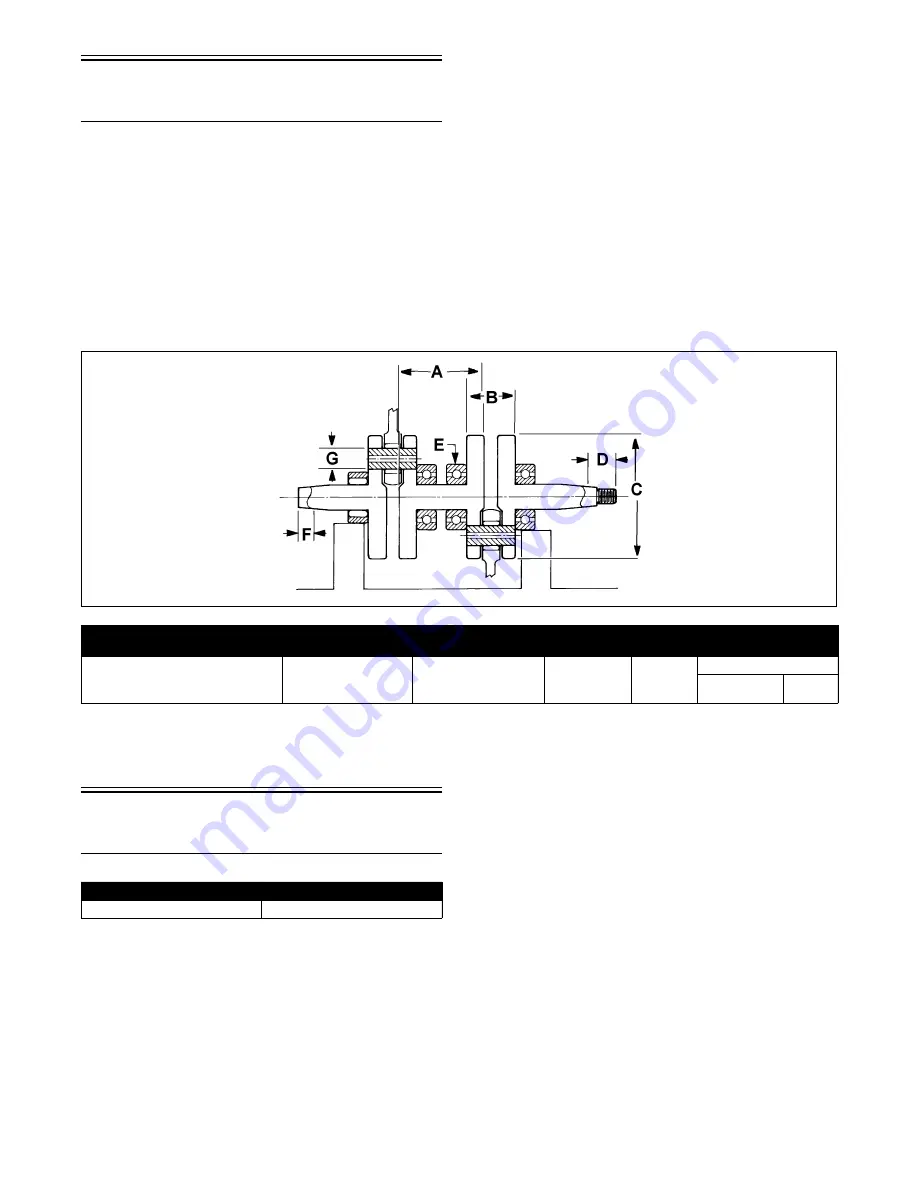

For those who have crankshaft work sent out to another shop, it is advisable to provide them with this information.

To use the specifications, first refer to the drawing; then find the letter which indicates the specification and refer to

the chart below the illustration. Be sure to note the proper engine column. Specifications are called out in both mil-

limeters and inches.

NOTE: We have given the proper location for checking crankshaft runout as the very edge of the straight

portion of the shaft where the oil seal makes contact. From the illustration, note that Arctic Cat has called

out three check points: at either end, out on the taper as shown, and also on the center bearing race. The

crankshaft is still supported on the outer bearings using V blocks. The maximum runout shouldn’t exceed

0.05 mm (0.002 in.).

728-144A

NOTE: Measure in from the shaft end the specified amount when checking runout at points D and F.

When checking runout in the center, place indicator on center of bearing as shown at point E. Maximum

runout at any of the 3 measuring points is ±0.05 mm (0.002 in.).

Cylinder Head Volume

Specifications

Engine

Bore X

Stroke

A

B

C

G

Runout D

and F Point

(± .002)

500 cc

mm

(in.)

71 X 63

(2.795 x 2.480)

114.6 ± 0.15

(4.515 ± 0.006)

66.5 ± 0.15

(2.618 ± 0.006)

113.4 ± 0.4

(4.465 ± 0.015)

26.9

(1.062)

D 5

(0.196)

F 5

(0.196)

Engine type

Squish-Gap

500 cc

0.059 in.

Summary of Contents for 500 Sno Pro

Page 1: ...TM SHARE OUR PASSION Operator s Performance Manual Performance Manual 500 Sno Pro...

Page 2: ......

Page 6: ...NOTES...

Page 22: ...16 NOTES...

Page 68: ...62 NOTES...

Page 92: ...86 NOTES...

Page 93: ...87 NOTES...

Page 94: ...88 NOTES...

Page 95: ...Printed in U S A Trademarks of Arctic Cat Inc Thief River Falls MN 56701 p n 2258 721...