44

NOTE: Install the bearings by sliding each bear-

ing onto the crankshaft making sure the dowel-pin

hole in the outer race is properly positioned and

will align with its hole and pin in the crankcase.

CM161

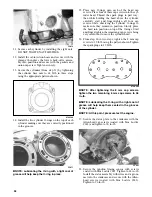

Reed Valve Assembly

1. Inspect the reed valves, stoppers, and valve blocks

for cracks or any deterioration.

CM162

2. Wash the reed valves, stopper, and cage assembly

in parts-cleaning solvent and blow dry.

3. Inspect the reed stopper height. Using a caliper,

measure the distance from the seat to the bottom

outer tip edge of the stopper. Measurement must

not exceed specifications. If measurement is not

within specifications, either bend or replace the

reed stopper.

CM163

4. Inspect the reed-to-seat clearance. Using a feeler

gauge, measure the clearance. Clearance must be

less than 0.008 in. If clearance is not within speci-

fications, replace the reed valve.

5. To assemble, place the reed valves on the cage

with its clipped corner positioned to the lower

right hand corner of the cage. Place the reed stop-

per assembly into position and secure with the

screws tightened to 48 in.-lb.

CM164A

Measuring Critical Components

NOTE: Critical engine specifications charts can

be found in Section 1 of this manual.

Cylinder Head Volume

(Squish-Gap Method)

To check the squish gap, a micrometer and two heavy

pieces of solder will be needed.

1. Remove the spark plugs from the engine.

2. Simultaneously insert two pieces of solder down

through the spark plug hole and push them up

against the inner cylinder bore towards the MAG-

side and PTO-side of the cylinder.

3. Pull the recoil rope and crank the engine over sev-

eral times while the solder is being held firmly in

place.

4. Remove both pieces of solder from the cylinder.

Using the micrometer, measure the very end of the

squeezed solder piece. Record the reading.

NOTE: If the solder hasn’t been squeezed by the

piston, a larger piece of solder must be used.

Repeat procedure.

5. Using the opposite end of the solder pieces, insert

them down through the spark plug hole towards

the PTO-side and MAG-side of the cylinder. Push

on the solder until they contact the inner cylinder

bore.

6. Pull the recoil rope and crank the engine over sev-

eral times. Remove both pieces of solder from the

cylinder and measure the opposite squeezed ends

with a micrometer. Record reading.

Summary of Contents for 500 Sno Pro

Page 1: ...TM SHARE OUR PASSION Operator s Performance Manual Performance Manual 500 Sno Pro...

Page 2: ......

Page 6: ...NOTES...

Page 22: ...16 NOTES...

Page 68: ...62 NOTES...

Page 92: ...86 NOTES...

Page 93: ...87 NOTES...

Page 94: ...88 NOTES...

Page 95: ...Printed in U S A Trademarks of Arctic Cat Inc Thief River Falls MN 56701 p n 2258 721...