46

2. Insert a snap gauge into each piston-pin bore; then

remove the gauge and measure it with a microme-

ter. The diameter measurement must be within

0.8661-0.8665 in. Take two measurements to

ensure accuracy.

AC092

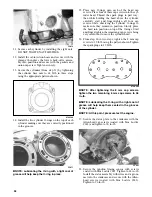

Connecting-rod Small End Bore

1. Insert a snap gauge into each connecting-rod small

end bore; then remove the gauge and measure it

with a micrometer.

AN061

2. The diameter measurement must be within

1.0631-1.0634 in.

Crankshaft Runout

0742-727

1. Using the V Blocks, support the crankshaft on the

surface plate.

NOTE: The V blocks should support the crank-

shaft on the outer bearings.

2. Mount a dial indicator and base on the surface

plate. Position the indicator contact point against

the crankshaft location point A (PTO-end) from

the crankshaft end. Zero the indicator and rotate

the crankshaft slowly. Note the amount of crank-

shaft runout (total indicator reading).

NOTE: For runout location point specifications,

see Crankshaft Runout/Repair Specifications in

Section 1 of this manual.

3. Position the indicator contact point against the

crankshaft location point B (MAG-end) from the

crankshaft end. Zero the indicator and rotate the

crankshaft slowly. Note the amount of crankshaft

runout (total indicator reading).

FC046

4. Position the indicator contact point against the

crankshaft at location point C (center). Zero the

indicator and rotate the crankshaft slowly. Note

the amount of crankshaft runout (total indicator

reading).

5. If runout exceeds 0.002 in. at any of the check-

points, the crankshaft must be either straightened

or replaced.

Assembling Engine

NOTE: The use of new gaskets and seals is rec-

ommended when assembling the engine.

NOTE: Prior to assembling the engine, use parts

cleaning solvent and compressed air and thor-

oughly clean the threaded holes of the crankcase

and cylinders to properly tighten.

NOTE: When the use of a lubricant is indicated,

use Arctic Cat Synthetic APV 2-Cycle Oil.

1. Apply a thin coat of grease to the inner seal lips of

the water pump seal.

! WARNING

Always wear safety glasses when drying components

with compressed air.

Summary of Contents for 500 Sno Pro

Page 1: ...TM SHARE OUR PASSION Operator s Performance Manual Performance Manual 500 Sno Pro...

Page 2: ......

Page 6: ...NOTES...

Page 22: ...16 NOTES...

Page 68: ...62 NOTES...

Page 92: ...86 NOTES...

Page 93: ...87 NOTES...

Page 94: ...88 NOTES...

Page 95: ...Printed in U S A Trademarks of Arctic Cat Inc Thief River Falls MN 56701 p n 2258 721...