65

NOTE: After testing the oil pump, the oil pump

must be correctly synchronized with the throttle

bodies (see Synchronizing Oil-Injection Pump).

Testing Oil-Injection Check Valves

In the event an engine problem occurs due to lack of

lubrication, the oil-injection pump check valves should

be tested using a vacuum pump to make sure the check

valves are operating properly.

When testing the check valves, remove them from the

pump assembly.

1. Remove the check valves from the oil-injection

pump.

731-551A

2. Attach the vacuum test pump hose to the check

valve.

3. Squeeze the vacuum pump handle and watch the

pump gauge. The check valve should release at

4.5-5 lb and again reset itself at 3.5-4 lb. If

“release” and “reset” are not within specifications,

replace the check valve.

4. Record the “release” and “reset” readings for the

valve; then perform the test on the other valve.

The “release” and “reset” readings must fall within

specifications and must be within 1.5 lb of each

other. If either or both are not met, replace the

check valves.

5. If the check valves are within specifications but

the oil-injection usage is not, replace the oil-injec-

tion pump.

SPARK PLUGS

Correct gap is 0.7-0.8 mm (0.028-0.031 in.).

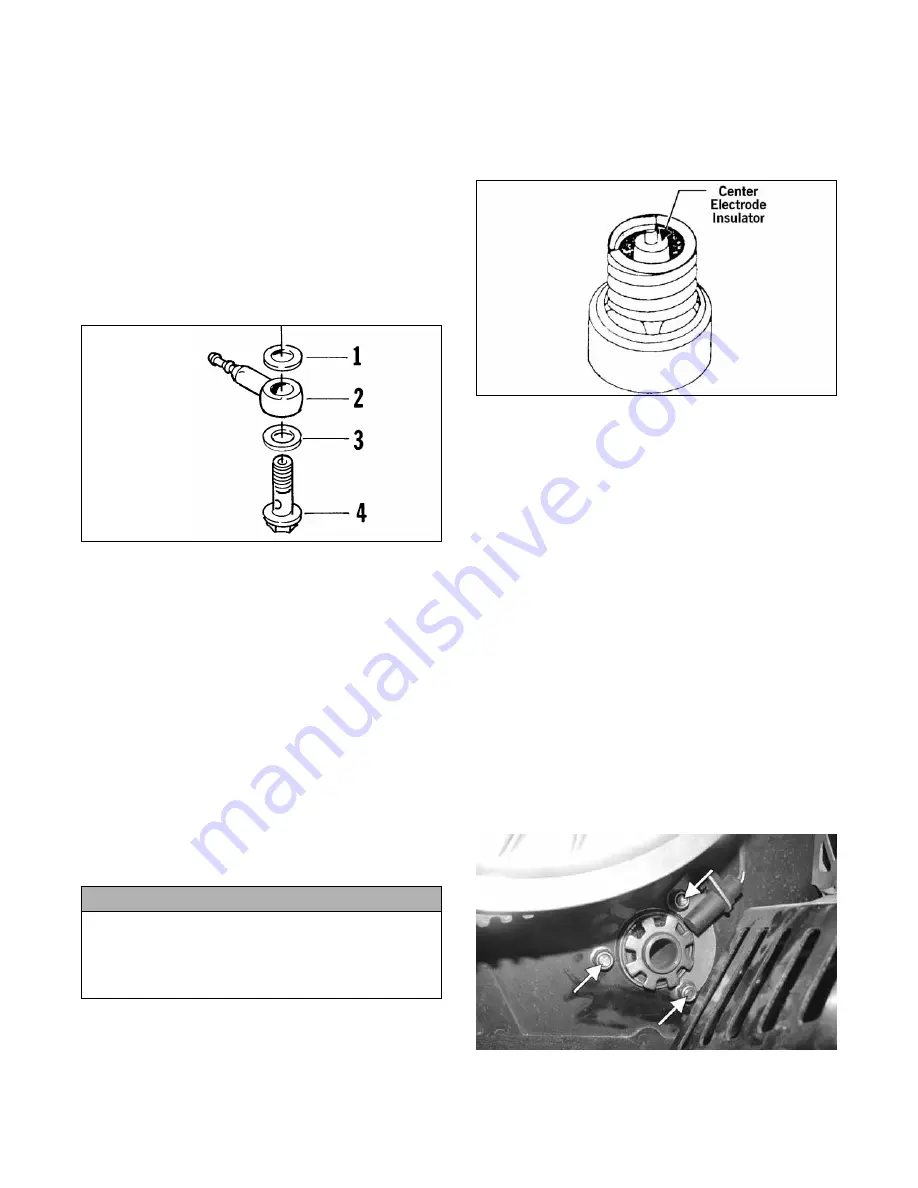

Checking Spark Plugs

To check spark plug condition and to aid in determin-

ing correct fuel/air mixture, pull the spark plug caps

off the spark plugs, remove the spark plugs, and exam-

ine the condition of the center electrode insulator of

each spark plug.

0725-048

A. TAN or LIGHT BROWN insulator indicates

correct spark plugs (heat range).

B. LIGHT GRAY or WHITE insulator indicates

overheating of the engine. This condition is

caused by a too lean condition, ignition timing

set too high, or incorrect spark plugs (heat

range too hot).

C. BLACK insulator indicates fuel in the combus-

tion chamber is not burning completely. This

condition is caused by a too rich condition.

TRACK DRIVE

Removing

1. Remove the hood and right and left side panels

and set aside; then remove the resonator.

2. Place a suitable safety stand beneath the rear bum-

per taking the weight of the snowmobile off the

rear suspension.

3. Remove the three nuts securing the left side of the

track drive and discard.

RS079A

4. Remove the cap screws securing the slide rail

assembly.

CAUTION

Whenever servicing the oil-injection system, use a

100:1 gas/oil mixture in the gas tank to ensure ade-

quate engine lubrication. Failure to use the 100:1 mix-

ture to the oil-injection system will result in severe

engine damage.

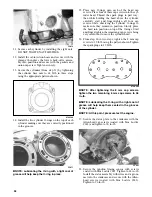

KEY

1. Gasket

2. Check Valve

3. Gasket

4. Union

Summary of Contents for 500 Sno Pro

Page 1: ...TM SHARE OUR PASSION Operator s Performance Manual Performance Manual 500 Sno Pro...

Page 2: ......

Page 6: ...NOTES...

Page 22: ...16 NOTES...

Page 68: ...62 NOTES...

Page 92: ...86 NOTES...

Page 93: ...87 NOTES...

Page 94: ...88 NOTES...

Page 95: ...Printed in U S A Trademarks of Arctic Cat Inc Thief River Falls MN 56701 p n 2258 721...