3-27

3

8. Rotate the crankshaft clockwise 180° and repeat

steps 5-7 on the other cylinder.

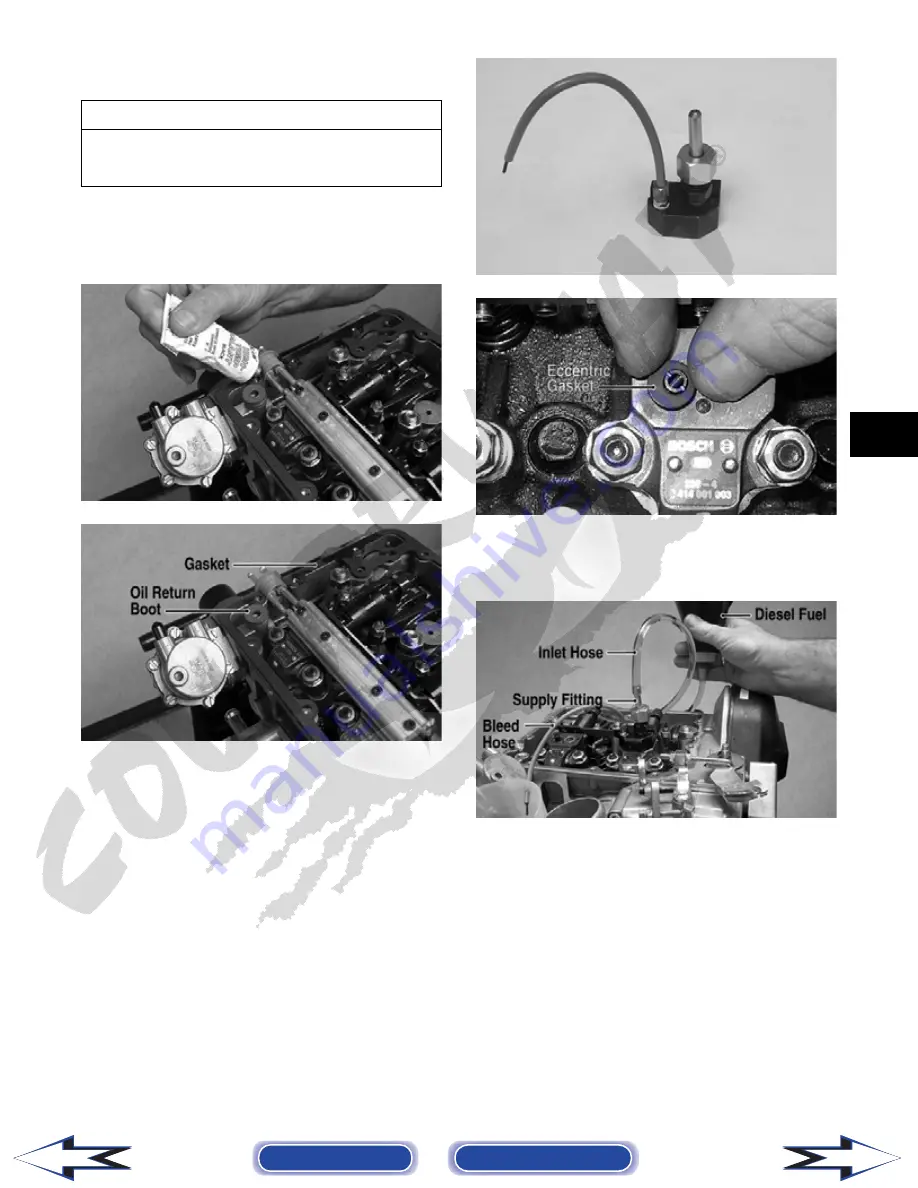

9. Place a small bead of high-temperature sealant on

the fuel rail seal; then carefully install the valve

cover with a new gasket and oil return boot.

Tighten to specifications.

DE406

DE405B

10. Connect the oil pressure switch connector and the

crankcase ventilator hose; then install the air filter

assembly and secure with the existing hardware.

Tighten securely.

11. Install the front body panel; then install the front

rack and splash panels (see Section 8).

STATIC INJECTOR TIMING

To set static injector timing, use the following proce-

dure.

1. Remove the valve cover and fuel rail (see Unit

Injectors in this sub-section).

2. Install the Timing Fuel Block (p/n 0444-234) on

the injector using the eccentric gasket over the

check valve in place of the O-ring.

DE572

DE444A

3. Connect a suitable container filled with clean die-

sel fuel to the supply fitting using an inlet hose;

then place a small cup under the bleed hose.

DE403B

4. Rotate the engine in the direction of rotation

(clockwise) until the #2 (flywheel-side) piston is at

top-dead-center (TDC) on the compression stroke

(reference mark (D) aligned to TDC index mark

(A) and valves closed).

AT THIS POINT

If engine is being assembled, static injector timing

should be adjusted (see Top-Side Components in

this section).

Back to TOC

Back to Section TOC

Next

Back