3-64

DE363

DE362

NOTE: Undersized connecting rod and main

bearings are available in 0.25 mm (0.010 in.) and

0.50 mm (0.020 in.) sizes. Use of undersized bear-

ings will require the crankshaft journals to be

machined to the correct size by a qualified

machine shop.

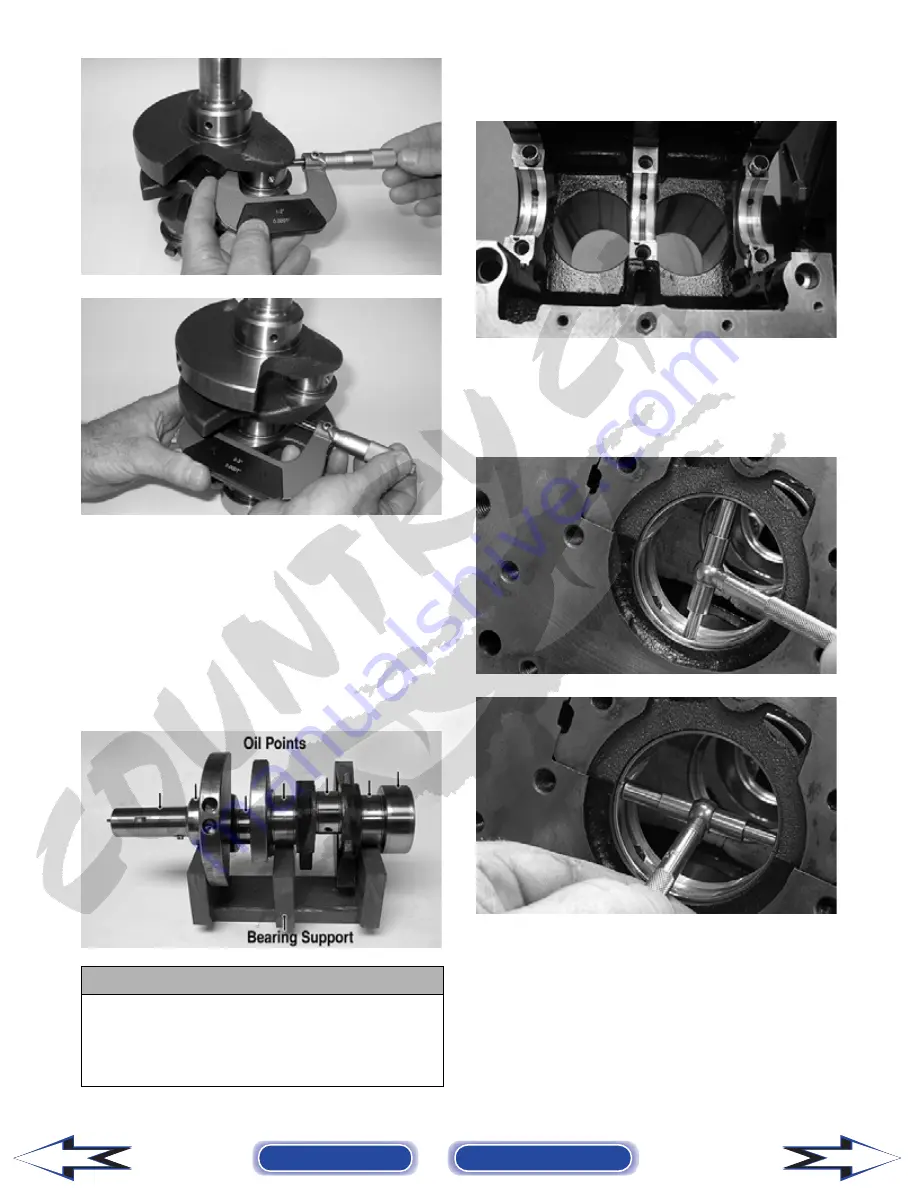

12. Lightly coat the crankshaft journals with clean oil.

If no machining is required, set aside until assem-

bly.

DE620A

13. Remove the main bearing caps from the main

bearing saddles; then install the bearing inserts

into the correct locations.

DE376

14. Install the main bearing caps and tighten to speci-

fications; then being careful not to mar the inserts,

measure the main bearing bores using an appropri-

ate inside micrometer/snap gauge. Record the

measurements.

DE609

DE610

15. Measure the crankshaft main bearing journals and

record the measurements.

! CAUTION

Always support the crankshaft equally at the main

bearing journals or stand the crankshaft on the fly-

wheel end. Do not drop or strike the crankshaft or

engine damage caused by crankshaft misalignment

may occur.

Back to TOC

Back to Section TOC

Next

Back