58

DRIVE CLUTCH AND DRIVEN

PULLEY

— Keeping the drive clutch

and driven pulley clean should be the pri-

mary consideration of the operator. The

drive clutch and driven pulley can be

cleaned of any drive belt accumulation

using compressed air. The sheaves can be

cleaned using a clean cloth and parts-

cleaning solvent.

DRIVE CLUTCH/DRIVEN PULLEY

OFFSET

— If premature drive belt wear

is experienced or if the drive belt turns

over, offset must be checked. Also, offset

must be checked whenever either the

drive clutch or driven pulley is serviced.

NOTE: For checking offset, it is

necessary to use Clutch Alignment

Bar (p/n 0644-496). This special tool

can be purchased from an autho-

rized Arctic Cat snowmobile dealer.

To check offset, use the following proce-

dure.

1. Open the left-side access panel; then

remove the belt guard.

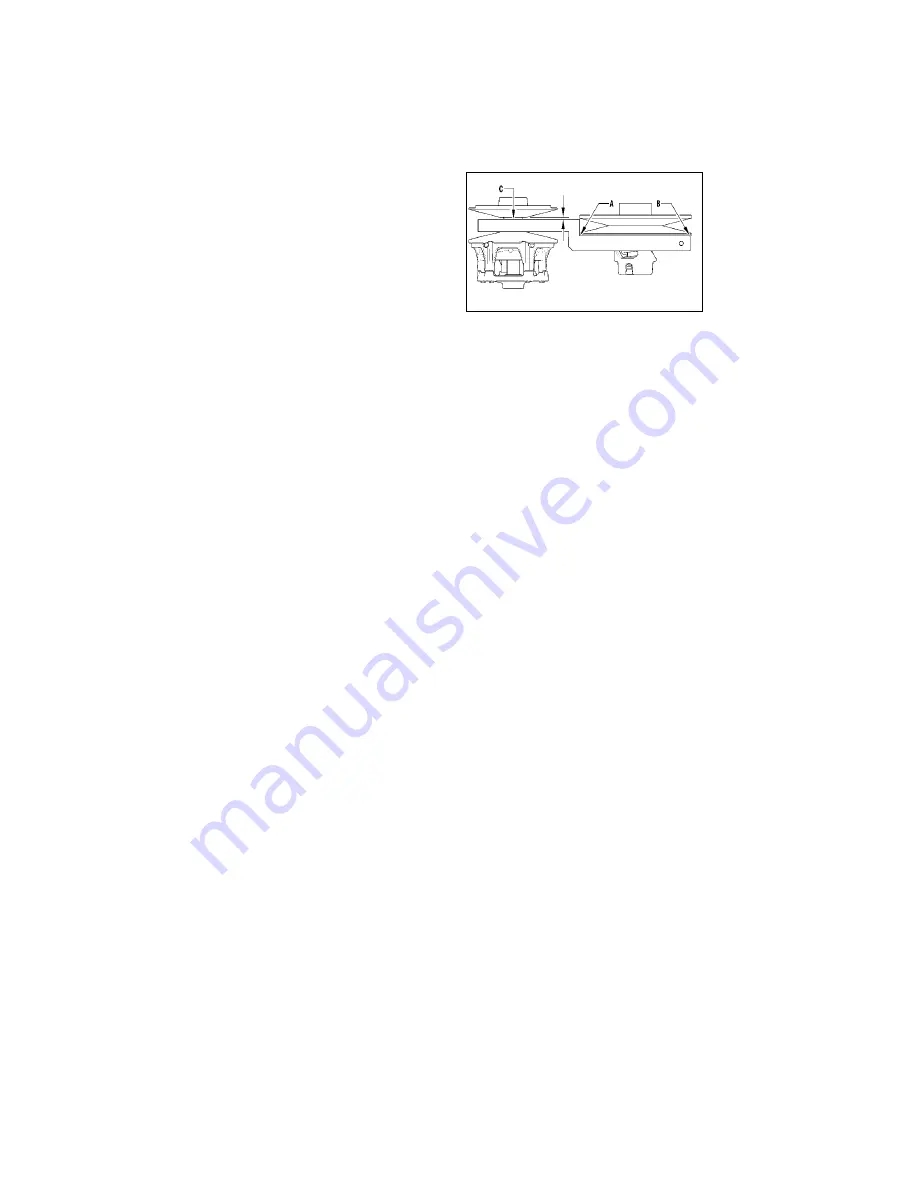

2. Install the clutch alignment bar

between the drive clutch sheaves.

3. Allow the bar to rest on the drive

clutch shaft and against the outside

edge of the driven pulley stationary

sheave.

NOTE: The alignment bar must

extend beyond the front edge of the

drive clutch.

4. With the bar against the outside edge

of the driven pulley stationary

sheave at points A and B, the bar

should just clear the inside edge of

the stationary sheave of the drive

clutch and rest on the stationary

shaft at point C with a maximum

0.060 in. clearance at point C. At

this point, measurement between

points A and C should be 1.507 in.

(with a maximum 0.060 in. clear-

ance). If the bar either will not clear

the inside edge or is more than the

specified amount, the offset must be

corrected.

0745-177

NOTE: If the offset is out of speci-

fication, take the snowmobile to an

authorized Arctic Cat Snowmobile

dealer for drive system evaluation

and/or servicing. This service is at

the discretion and expense of the

snowmobile owner.

DRIVE CLUTCH/DRIVEN PULLEY

PARALLELISM

— If premature drive

belt wear is experienced or if the drive

belt turns over, parallelism must be

checked. Also, parallelism must be

checked whenever either the drive clutch

or driven pulley is serviced.

NOTE: For checking parallelism, it

is necessary to use Clutch Align-

ment Bar (p/n 0644-509). This special

tool can be purchased from an

authorized Arctic Cat Snowmobile

dealer.

To check parallelism, use the following

procedure.

1. Remove the drive belt; then open the

driven sheaves and place clutch

alignment bar between the sheaves.

Release the sheaves.

2. Check the parallelism of the drive

clutch/driven pulley using the paral-

lelism bar and reference points X

and Y with the parallelism bar

between the driven sheaves. Using a

caliper or a machinist’s scale, mea-

sure X and Y from the back side of

the parallelism bar to the back side

of the drive clutch sheave. Measure-

ment Y must be 0.060 in. ± 0.020 in.

more than measurement X, but Y

must not exceed measurement X by

more than 0.100 in.

Summary of Contents for Bearcat 570 XT

Page 7: ...3 Snowmobile Safety Rules...

Page 67: ...63 NOTES...