MAINTENANCE

29

6. Release the brake lever lock.

TRACK TENSION

Track tension is directly related to

the overall performance of the

snowmobile. If the track is too

loose, it may slap against the tunnel

causing wear or it may “ratchet” on

t h e t r a c k d r i v e s p r o c k e t s . I f

extremely loose, the idler wheels

may climb over the track lugs forc-

ing the track against the tunnel caus-

ing the track to “lock.” Arctic Cat

recommends that the track tension

be checked daily during the first 300

miles of operation and once a week

thereafter and adjusted according to

need. The track will stretch and take

a “set” during break-in. After break-

in, track deflection must be main-

tained at 50.8-57.2 mm (2 - 2 1/4

in.) @ 20 lb.

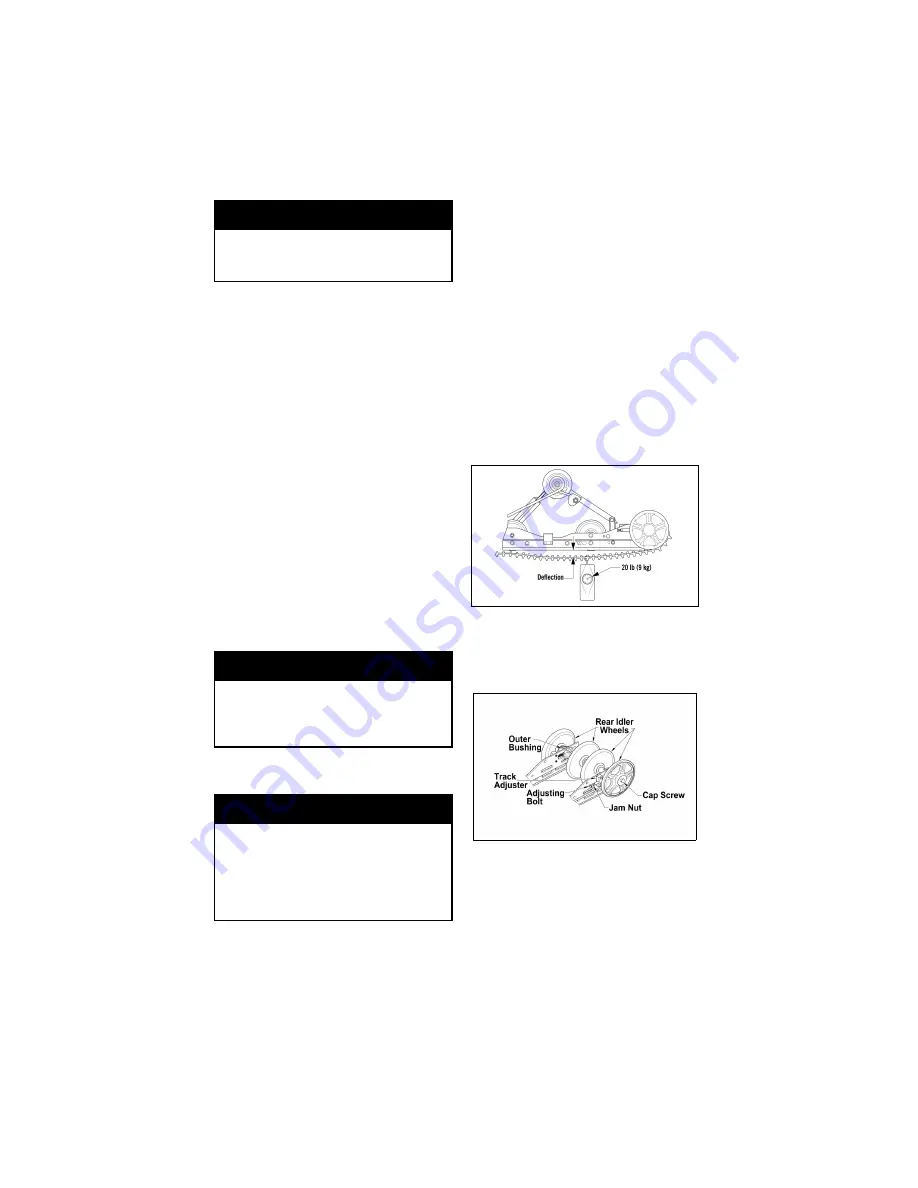

Checking Track Tension

1. Remove excess ice and snow

buildup from the track, track

drive sprockets, and the inside

of the skid frame.

2. With the gas tank nearly empty

(less than 1/4 full), lay the

snowmobile on its side. A piece

of cardboard should be used to

protect the finish on the hood

and belly pan.

3.

Exert moderate pressure

(approximately 20 lb) at mid-

span of the lower track section.

Measure the distance between

the bottom of the wear strip and

the inside surface of the track.

The measurement must be

within specifications. If the

measurement is not within

specifications, an adjustment is

necessary.

0740-329

Adjusting Track Tension

1. Loosen the rear idler wheel

adjusting bolt jam nuts.

739-636A

NOTE: To ensure proper track

tension adjustment, perform all

adjustments on both sides of the

snowmobile.

! WARNING

Never operate the snowmobile

without the belt guard secured in

place.

! WARNING

Track tension must be properly

m a i n t a i n e d . Pe rs o n a l i n j u r y

could result if a track is allowed

to become excessively loose.

! WARNING

D O N OT a t t e mp t t o ch e ck o r

adjust track tension with engine

running. Turn ignition key to the

OFF position. Personal injury

could result from contact with a

rotating track.

Summary of Contents for Crossfire 700 EFI (EB) 2006

Page 1: ......

Page 7: ...SNOWMOBILE SAFETY RULES 3 SNOWMOBILE SAFETY RULES...

Page 8: ...4 SNOWMOBILE SAFETY RULES SNOWMOBILE SAFETY RULES Cont...

Page 47: ...43 NOTES...

Page 48: ...44 NOTES...

Page 49: ...45 NOTES...

Page 50: ...46 NOTES...

Page 52: ...p n 2257 296 Printed in the U S A Trademarks of Arctic Cat Inc Thief River Falls MN 56701...