146

WC692

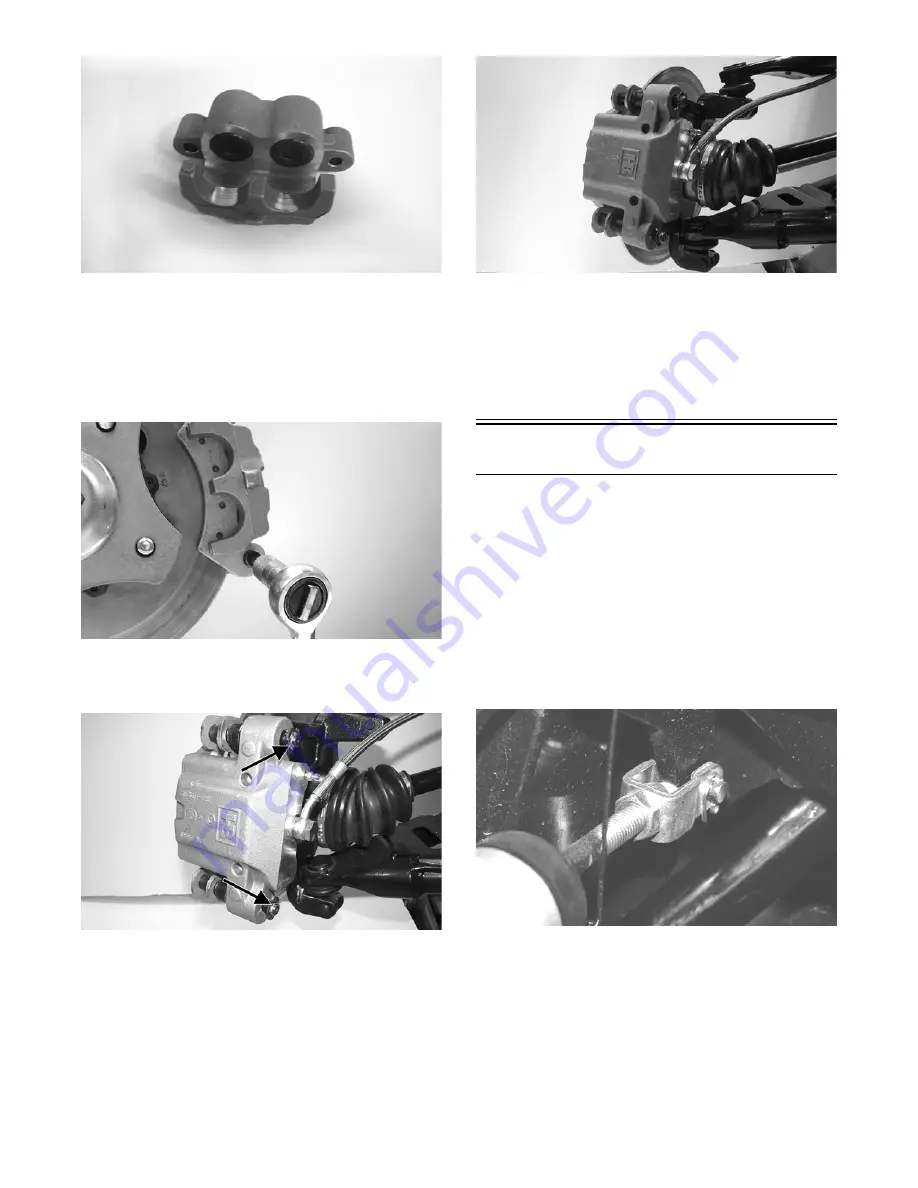

3. Using silicon grease, lubricate the O-rings and install

into the anchor bolt bores making sure the correct

size of O-rings are installed in the correct locations

(thicker O-rings on bleed screw end of calipers).

4. Install the caliper and brake pads onto the brake disc

and secure to the knuckle with the anchor bolts.

Tighten to 35 ft-lb.

WC606

5. Install the E-clips; then using new crush washers,

connect the brake banjo fitting to the caliper and

tighten to 20 ft-lb.

WC611A

WC609

6. Fill the reservoir; then bleed the brake system (see

Periodic Maintenance/Tune-Up.)

7. Install the wheels and using a crisscross pattern,

tighten the wheel nuts in 20 ft-lb increments to a final

torque of 40 ft-lb (steel wheel), 60 ft-lb (aluminum

wheel w/black nuts), or 80 ft-lb (aluminum wheel

w/chrome nuts).

Master Cylinder Assembly

NOTE: The master cylinder is a non-serviceable

component; it must be replaced as an assembly.

Removing

1. Slide a piece of flexible tubing over one of the brake

caliper bleeder valves and direct the other end into a

container. Remove the reservoir cover; then open the

bleeder valve. Allow the brake fluid to drain until the

reservoir is empty.

2. Remove the cotter pin and pivot pin from the yoke;

then remove two cap screws securing the master cyl-

inder assembly to the frame.

PR338