45

CC132D

2. Remove the valve seal and the lower remaining

spring seat. Discard the valve seal.

CC136D

NOTE: The valve seals must be replaced.

3. Remove the valve springs; then invert the cylinder

head and remove the valves.

Measuring Valve Guide (Bore)

1. Insert a suitable bore gauge 1/2 way into each valve

guide bore and record the measurement.

2. Acceptable inside diameter range must be within

specifications.

3. If a valve guide is out of tolerance, it must be

replaced.

Servicing Valves/Valve Guides/Valve

Seats

If valves, valve guides, or valve seats require servicing or

replacement, Arctic Cat recommends the components be

taken to a qualified machine shop for servicing.

Installing Valves

1. Apply grease to the inside surface of the valve seals;

then place a lower spring seat and valve guide seal

over each valve guide.

CC144D

2. Insert each valve into its original location.

3. Install the valve springs with the painted end of the

spring facing away from the cylinder head.

NOTE: If the paint is not visible, install the ends of

the springs with the closest wound coils toward the

head.

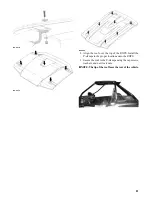

ATV-1011A

4. Place a spring retainer over the valve springs; then

using the valve spring compressor, compress the

valve springs and install the valve cotters.

PISTON ASSEMBLY

NOTE: Whenever a piston or pin is out of tolerance,

it must be replaced.

Removing Piston Rings

1. Starting with the top ring, slide one end of the ring

out of the ring-groove.

2. Remove each ring by working it toward the dome of

the piston while rotating it out of the groove.

CC400D

CAUTION

If valves are discolored or pitted or if the seating sur-

face is worn, the valve must be replaced. Do not attempt

to grind the valves or severe engine damage may occur.