A -1

SUMMARY

A-1

64

44

20

0

600

I

2

(

A

)

U

2

(

V

)

Working

point

Volt-ampere characteristic

The relation of the rated

loading voltage&welding

current

64

44

20

0

600

I

2

(

A

)

U

2

(

V

)

Working

point

Volt-ampere characteristic

The relation of the rated

loading voltage&welding

current

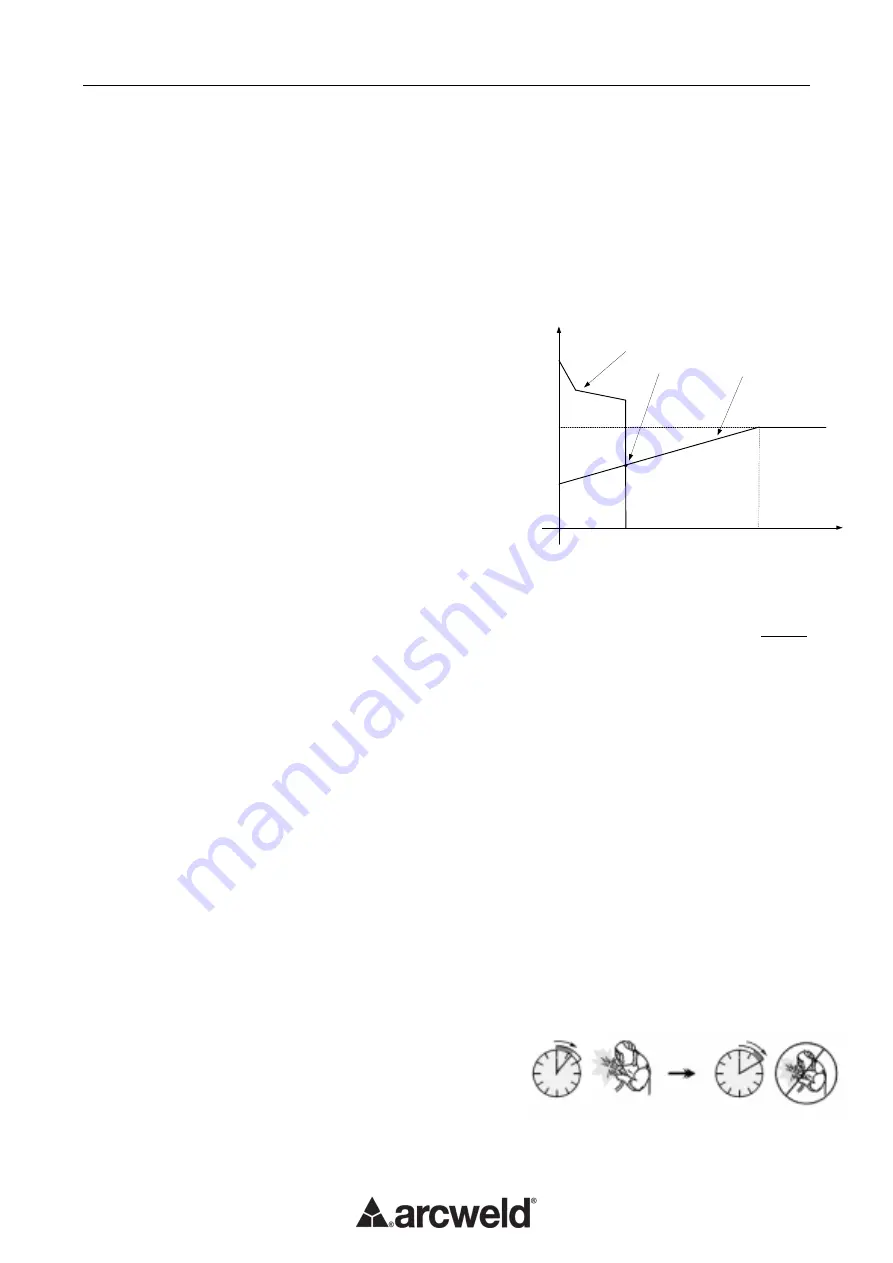

VOLT-AMPERE

CHARACTERISTIC

The

arcweld

®

machine has excellent volt-

ampere characteristic, refer to the

following graph. In TIG welding, the

relationship between rated loading voltage

U

2

and welding current I

2

is as follows:

When I

2

≤600A

,

U

2

=

10

+

0.04 I

2

(

V

);

When I

2

>

600A

,

U

2

=

34

(

V

)

GENERAL INTRODUCTION

The

arcweld

®

TIG 205 DC is a new generation of multi

functional high quality welding machine. The power

source adopts a microcomputer system control, dual

current loop PWM control, full-bridge high frequency

inverter system. It has convenient operation, stable

performance, small size and high duty cycle. The power

source is mainly applied to the welding of stainless steel,

carbon steel and other metals.

CHARACTERISTICS

To ensure a high success rate of arc starting. The

power source incorporates a high voltage and

pulse(High frequency) arc start circuit but without a

discharge circuit so that it makes arc start easier and

safer. Lift arc start is another option for those wishing

to avoid electromagnetic interference.

Safety, efficiency. From a machine with protection

features such as precharge function, under voltage

protection, over voltage protection, over heat

protection, over current protection and output short

circuit protection. Especially adopted protection

circuit against electric shock: In MMA mode, the

machine will turn off the main loop output power

within 2 seconds after ending welding, the advantage

is safer operation, and saving power.

One machine, 4 types of welding processes:

MMA

DC TIG

DC TIG/PULSE

DC TIG/SPOT

PWM - Pulse-Width Modulation;

MMA - Manual Metal Arc welding;

TIG - Tungsten Inert Gas welding.

68

34

10

0

600

I

2

(

A

)

U

2

(

V

)

Working

point

Volt-ampere characteristic

The relation of the rated

loading voltage&welding

current

STACKING

The

arcweld

®

inverter machine

CAN’T

be

stacked when welding.

TILTING

Place the machine directly on a secure, level

surface. Do not place or operate the machines

on a surface with an incline greater than 15°

from horizontal. The machine may topple over

if this procedure is not followed.

WELDING CAPABILITY

Please see Technical Specifications in the

Installation Section for rated outputs for the

arcweld

®

inverter machine. It is capable of

higher duty cycles at lower output currents.

If the duty cycle is exceeded, a thermal

protector will shut off the output until the

machine cools.

A Duty Cycle of 60% example is:

Weld for 6 minutes Break for 4 minutes