20

AVENSIS -

Item code: BH137

.

Instruction Manual

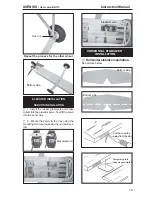

1. Using a modeling knife, cut away the

covering from the fuselage for the stabilizer

and remove it.

2. Draw a center line onto the horizontal

stabilizer. Then slide the horizontal into the

fuselage.

3. Mark the shape of the vertical on the left

and right sides onto the horizontal stabilizer

using a felt-tip pen

Mark pen

4. Remove the stabilizer. Using the lines

you just drew as a guide, carefully remove the

covering from between them using a modeling

knife.

When cutting through the covering to

remove it, cut with only enough pressure

to only cut through the covering it’s self.

Cutting into the balsa structure may

weaken it. This could lead to possible fail-

ure during flight

Remove covering.

5. When you are sure that everything is

aligned correctly, mix up a generous amount

of 30 minute epoxy. Apply a thin layer to the

top and bottom of the stabilizer mounting area

and to the stabilizer mounting platform sides

in the fuselage. Slide the stabilizer in place and

re-align. Double check all of your measure-

ments one more time before the epoxy cures.

Remove any excess epoxy using a paper

towel and rubbing alcohol and hold the stabi-

lizer in place with T-pins or masking tape.

Assemble then apply drops of thin

C/A to center of hinge,on both sides.

Top side

Center line.