Instruction Manual book

Recommended R.C: 4 channels with

4-5 servos.

Propeller : 13 x 6.

Speed Control: 60A.

Electric Motor: AXI 2826/10.

Battery: 4-5 Cells-Li-Poly-14.8-18.5v- 5.000 mAh - 20c.

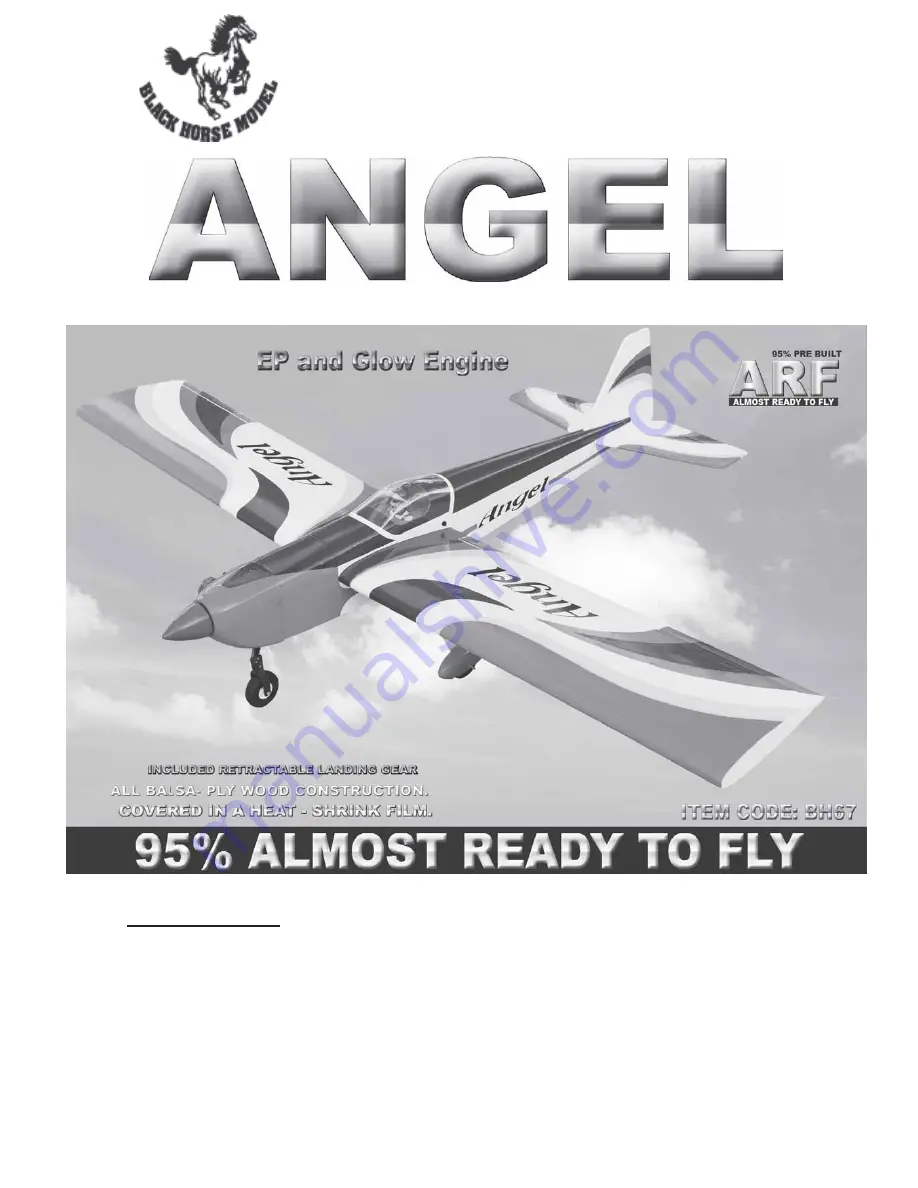

SPECIFICATION

Made in Vietnam.

Wingspan : 1,580mm. 62.20 in.

Length : 1,265 mm. 49.81in.

Weight : 2.5kg. 5.50lbs.

Parts Listing required (not included).

Radio : 4 channels.

Servo : 5 servos.

Glow Engine : 46-55 cu.in. 2 stroke.