1 Introduction

Features

1

1

Introduction

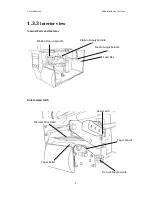

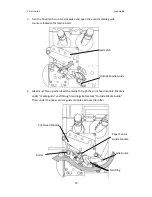

Thank you for purchasing an Argox iX4 Series industrial barcode printer. This

manual provides information about how to set up and operate your printer,

load media, ribbon and solve common problems. Illustrations are provided

to help you quickly become familiar with the printer.

1.1

Features

■

Fast Print Speed

Max. 8 IPS, fastest print speed in its class.

■

Communication

Standard: Ethernet, dual USB hosts, USB device, and RS-232.

Option: Wi-Fi, GPIO, Parallel, and Buzzer

■

Online management

Web management and SNMP v2 support

■

Duel USB host function

Stand-alone mode of scanner/ keyboard multiple data entry devices

■

New media calibration

Intelli mode & Auto-feed mode & Smart mode