10

TILLING HINTS (See Fig. 14)

CAUTION: Until you are accustomed to

handling your tiller, start actual field use

with throttle in slow position (mid-way

between “FAST” and “IDLE”).

• Tilling is digging into, turning over, and breaking up

packed soil before planting. Loose, unpacked soil helps

root growth. Best tilling depth is 4" to 6" (10-15 cm).

A tiller will also clear the soil of unwanted vege ta tion.

The de com po si tion of this vegetable mat ter enriches

the soil. Depending on the climate (rain fall and wind),

it may be advisable to till the soil at the end of the

growing season to further condition the soil.

• You will find tilling much easier if you leave a row

untilled between passes. Then go back between tilled

rows. (See Fig. 14) There are two reasons for doing

this. First, wide turns are much easier to negotiate than

about-faces. Sec ond, the tiller won’t be pulling itself,

and you, toward the row next to it.

•

Soil conditions are important for proper tilling. Tines will

not readily penetrate dry, hard soil which may con trib ute

to excessive bounce and difficult handling of your tiller.

Hard soil should be mois tened before tilling; however,

extremely wet soil will “ball-up” or clump during tilling.

Wait until the soil is less wet in order to achieve the

best results. When tilling in the fall, re move vines and

long grass to prevent them from wrapping around the

tine shaft and slowing your tilling operation.

•

Do not lean on handle. This takes weight off the wheels

and reduces traction. To get through a really tough

section of sod or hard ground, apply upward pressure

on handle or lower the depth stake.

Fig. 14

Fig. 15

3

2

1

5

4

6

7

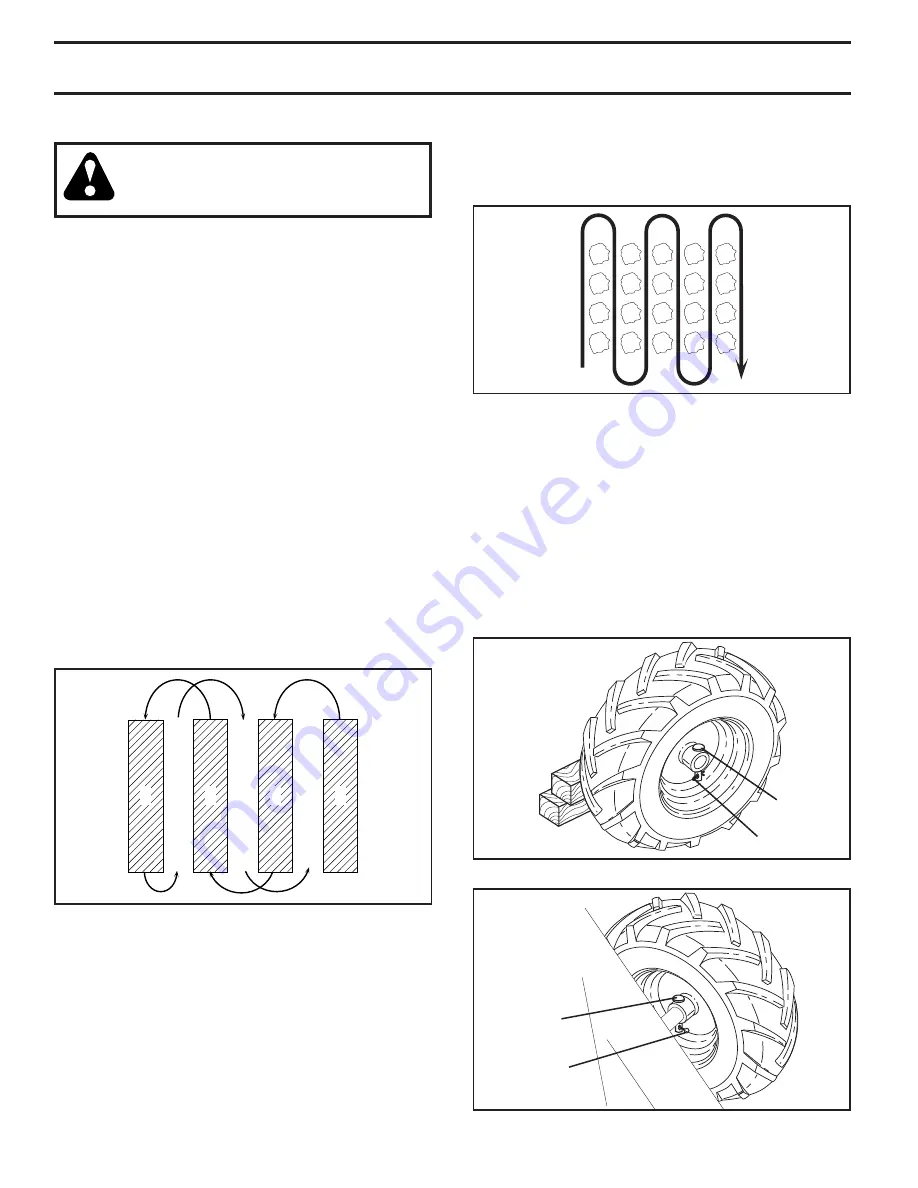

CULTIVATING

Cultivating is destroying the weeds between rows to pre-

vent them from robbing nourishment and moisture from the

plants. At the same time, breaking up the upper layer of

soil crust will help retain moisture in the soil. Best digging

depth is 1" to 3" (2.5-7.5 cm). Lower the outer side shields

to protect small plants from being buried.

• Cultivate up and down the rows at a speed which will

allow tines to uproot weeds and leave the ground in

rough condition, promoting no further growth of weeds

and grass (See Fig. 15).

ADJUST WHEELS FOR CULTIVATING

(See Figs. 16 and 17)

•

Place blocks under right hand side of tiller and remove

hairpin clip and clevis pin from right hand wheel.

• Move wheel outward approximately 1 inch until hole

in inner wheel hub lines up with inner hole in axle.

• Replace clevis pin and hairpin clip on inside of wheel

and remove blocks.

• Repeat preceding steps on left hand side.

NOTE

: In extremely rough conditions and while

cultivating, the wheels should be moved outward on the

axle for increased stability.

•

Do not lean on handle, this takes weight off the wheels,

reduces traction, and may cause the tiller to skip over

the ground.

•

Always lower the drag stake when using the for ward

rotating tine drive.

Fig. 16

Fig. 17

INNER VIEW

OF TIRE

CLEVIS PIN

HAIRPIN CLIP

OUTER VIEW

OF TIRE

HAIRPIN CLIP

CLEVIS PIN

OPERATION