EN – 68

2.

Remove pump from tank.

3.

Reconnect pump wires.

4.

Turn the ignition key to the ON position and listen for a

“humming” noise.

If fuel pump is silent, replace fuel pump.

If voltage is within range and fuel pump is operating

normally, the fuel pressure sensor is defective. Replace the

throttle body assembly. See Figure 166.

Code 28: High Battery Voltage

This trouble code will activate if ECU detects a higher

voltage from the stator.

1.

Start the engine. Refer to Operator’s Manual.

2.

Set a multi-meter to V AC and probe the red and black

stator connector wire. The output should be

11.5 V AC – 14 V AC at full throttle (3600 RPM).

If stator output measures over 14 V AC, replace stator. If

output is within range, advance to step 3. See Figure 155.

IMPORTANT:

If the engine is cold, it is normal for the

engine speed to be 100 RPM – 200 RPM higher until

operating temperature is reached.

3.

Set a multi-meter to V DC and probe the battery

connector at the battery terminals. With the engine

running at full throttle (3600 RPM), the output should

be 7.2 V DC – 8.4 V DC.

If DC output is higher than 8.4 V DC, replace ECU. See

Figure 154.

If DC output is within range and red trouble code persists,

replace ECU.

DIAGNOSTICS FOR NON-TROUBLE

CODES

IMPORTANT:

The following conditions and diagnostic

procedures apply to EFI components only.

Engine Starts and Loses Power

If the engine starts and loses power immediately, this is

usually an indication that the ECU does not detect an RPM

signal. The RPM signal is generated by the stator, which

also powers the hand warmers, headlight and charges the

ECU battery.

Common causes for RPM signal failure may be due to a

disconnected engine wire harness or a ground short in the

AC output wire from the stator to the ECU. Other possible

causes may include an ECU or engine-charging system

failure.

1.

Check wire harness connection to the ECU.

a. With the ignition key in the off position, check the

wire harness connections to the ECU. If

connections are secure, disconnect the 12-pin

and 14-pin connections to the ECU and inspect

connectors for bad connections or burn marks.

b. Check that all wire terminals are snug in their

connectors. If connections appear to be good,

reconnect wire harness and start engine to check

if issue is still present. If bad connection is

present, replace wire harness.

c. If issue is still present, advance to next step.

2.

Check the ECU.

a. Disconnect wire harness from ECU and test with a

new ECU to verify the original ECU is not cause

for malfunction. If malfunction is not resolved with

a new ECU, reconnect wire harness to original

ECU and continue diagnostics.

3.

Back probe the engine stator output connector. See

Figure 155.

a. Start the engine. Refer to Operator’s Manual.

b. At full throttle (3600 RPM), the stator output

MUST be 11.5 V AC – 14 V AC.

If AC voltage measures less than 11.5 V AC, remove

flywheel and replace stator.

Engine No-Start Condition

If the engine does not start, check for system power.

1.

Check EFI battery fuse.

2.

Check spark plug.

a. Stop engine, remove key and wait for all moving

parts to stop and for hot parts to cool.

b. Disconnect the spark plug wire and remove debris

from the spark plug area.

c. Remove spark plug.

d. Inspect the spark plug. Spark plug gap MUST be

0.7 mm – 0.8 mm (0.027" – 0.030"). Replace if the

electrodes are worn, fouled, or if the insulator is

cracked or chipped.

e. Position spark plug against engine block and pull

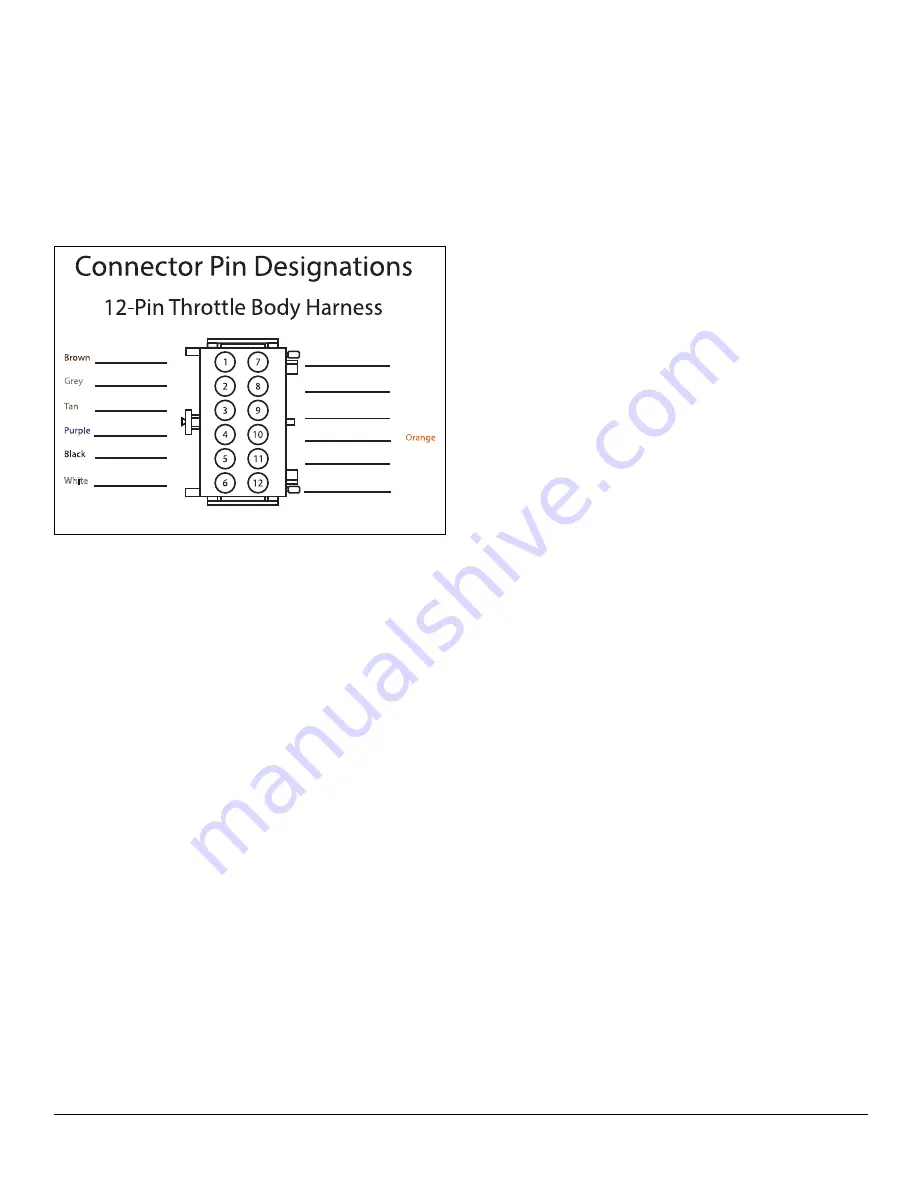

Engine Temperature

Potentiometer

Servo -

Servo +

B-

Injector-

Ext-ANA- (Potentiometer)

Fuel Pressure Input

Servo-Signal

Ext-ANA+ (Potentiometer)

ECU+

Pink

Blue

Yellow

Yellow

Pump-

Green

Red

Figure 161