EN – 19

5.

Place unit in service position and remove bottom

cover. See

Check attachment brake:

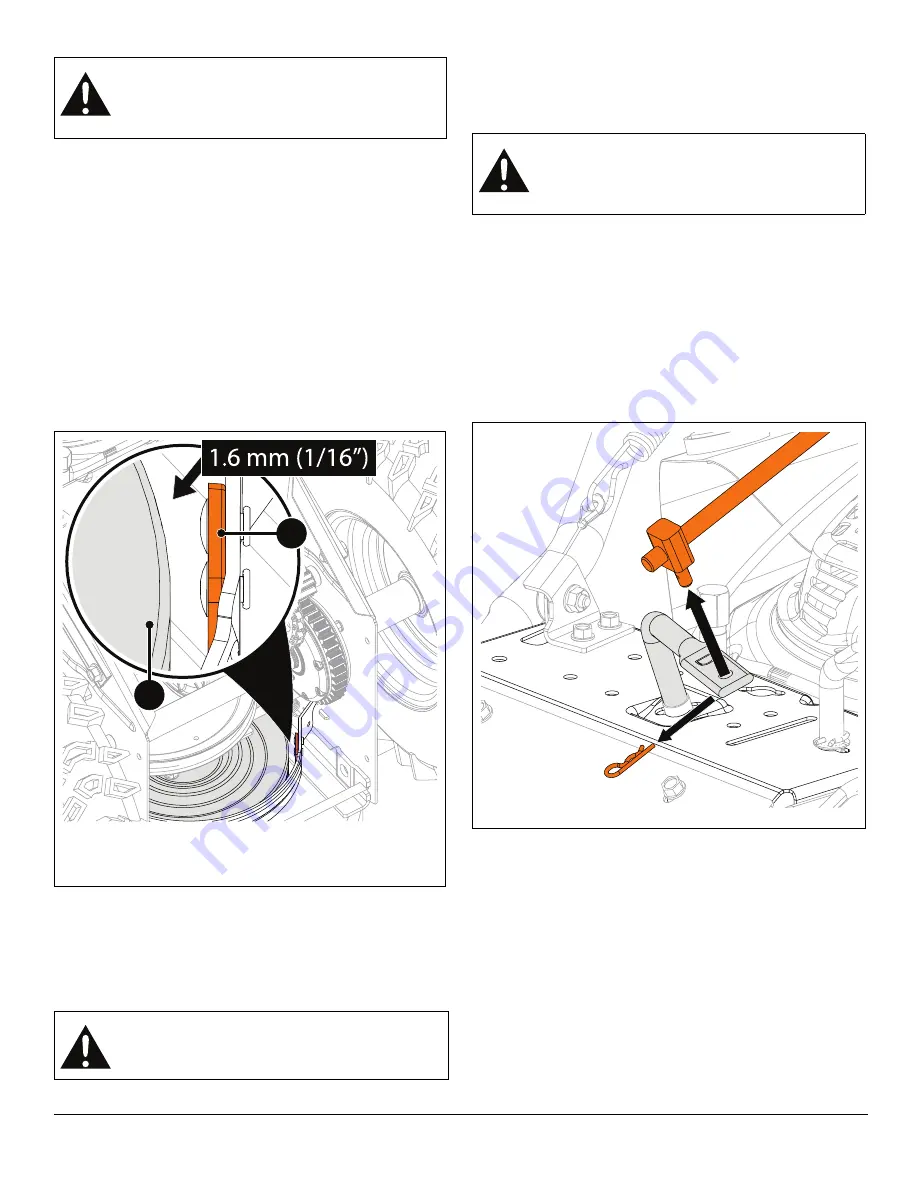

• When attachment clutch is disengaged, brake must

contact attachment belt or pulley, whichever is

closest.

• When attachment clutch is engaged, brake must be

more than 1.6 mm (1/16") away from attachment belt

or pulley, whichever is closest.

IMPORTANT:

If attachment clutch / brake is out of

adjustment, refer to Operator’s Manual for adjustment

procedure.

7.

Reinstall bottom cover and secure with two tapping

screws and four hex bolts.

8.

Return unit to operating position.

9.

Reconnect spark plug wire and fill fuel tank.

IMPORTANT:

Check all adjustments after first use.

FRICTION DISC REPLACEMENT

Remove Friction Disc

IMPORTANT:

Save all hardware for reinstallation.

1.

Stop engine, remove key and wait for all moving parts

to stop and for hot parts to cool.

2.

Disconnect spark plug wire.

3.

Place unit in service position and remove bottom

cover. See

on page 7 and

Remove hairpin securing adjustment pin to shift arm.

5.

Remove adjustment pin from shift arm.

6.

Remove snap clips from axle ends and remove

wheels.

WARNING:

AVOID INJURY. Before placing unit

in service position, drain fuel from tank and fuel

system. See

Ensure unit is secure and will not tip.

WARNING:

AVOID INJURY. Auger / impeller

must stop within 5 seconds when attachment

clutch lever is released.

Figure 33

1. Brake Pad

2. Attachment Pulley & Belt

WARNING:

AVOID INJURY. Before placing unit

in service position, drain fuel from tank and fuel

system. See

Ensure unit is secure and will not tip.

Figure 34