EN – 27

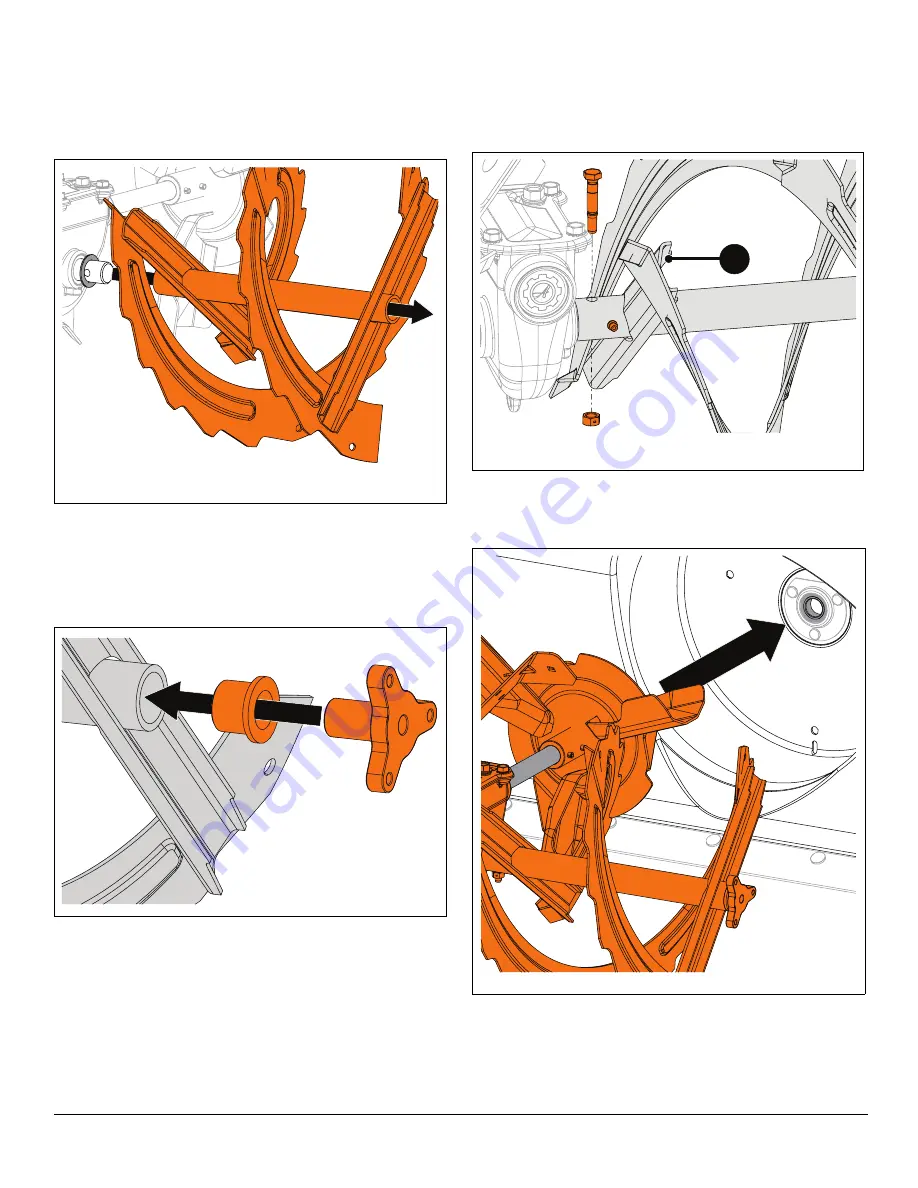

See Figure 57.

12. Remove auger. Use of penetrating oil or heat may be

necessary to remove auger.

IMPORTANT:

If rust is present on auger shaft, remove with

sand paper and wipe clean with oil.

Install Auger

IMPORTANT:

Ensure auger helix direction matches the

original auger orientation.

1.

Reinstall flange bushing and support bushing onto

auger end. See Figure 58.

Install auger onto auger shaft with auger kickers facing

gearcase.

IMPORTANT:

Ensure auger helix direction matches the

original auger orientation.

3.

Apply grease to grease zerk.

4.

Align holes in auger with holes in auger shaft and

reinstall shear bolt. Torque bolt to 7.9 N•m – 16.5 N•m

(5.8 lb-ft – 12.2 lb-ft). If torque wrench is unavailable,

tighten until bolts no longer spin freely. DO NOT

overtighten.

5.

Reinstall auger assembly into housing and seat

impeller shaft end into ball bearing at housing rear.

See Figure 60.

Figure 57

Figure 58

Figure 59

1. Kicker

Figure 60