EN – 45

Insert pinion shaft end into left side of frame.

7.

Position flat steel washer against pinion gear and

reinstall spring clip.

8.

Reinstall bottom cover and secure with two tapping

screws and four hex bolts.

9.

Ensure axle key is in position and reinstall wheel.

Secure with snap clip.

10. Return unit to operating position.

11. Reconnect spark plug wire and fill fuel tank.

DIFFERENTIAL GEAR REPLACEMENT

Remove Differential Gear

IMPORTANT:

Save all hardware for reinstallation.

1.

Stop engine, remove key and wait for all moving parts

to stop and for hot parts to cool.

2.

Disconnect spark plug wire.

3.

Place unit in service position and remove bottom

cover. See

on page 7 and

4.

Remove snap clips from axle ends and remove

wheels and axle keys. Take care to not lose axle keys.

Remove left outer flat steel washer from long axle.

6.

Remove E-ring from axle end.

7.

Remove long axle from differential and tractor

housing.

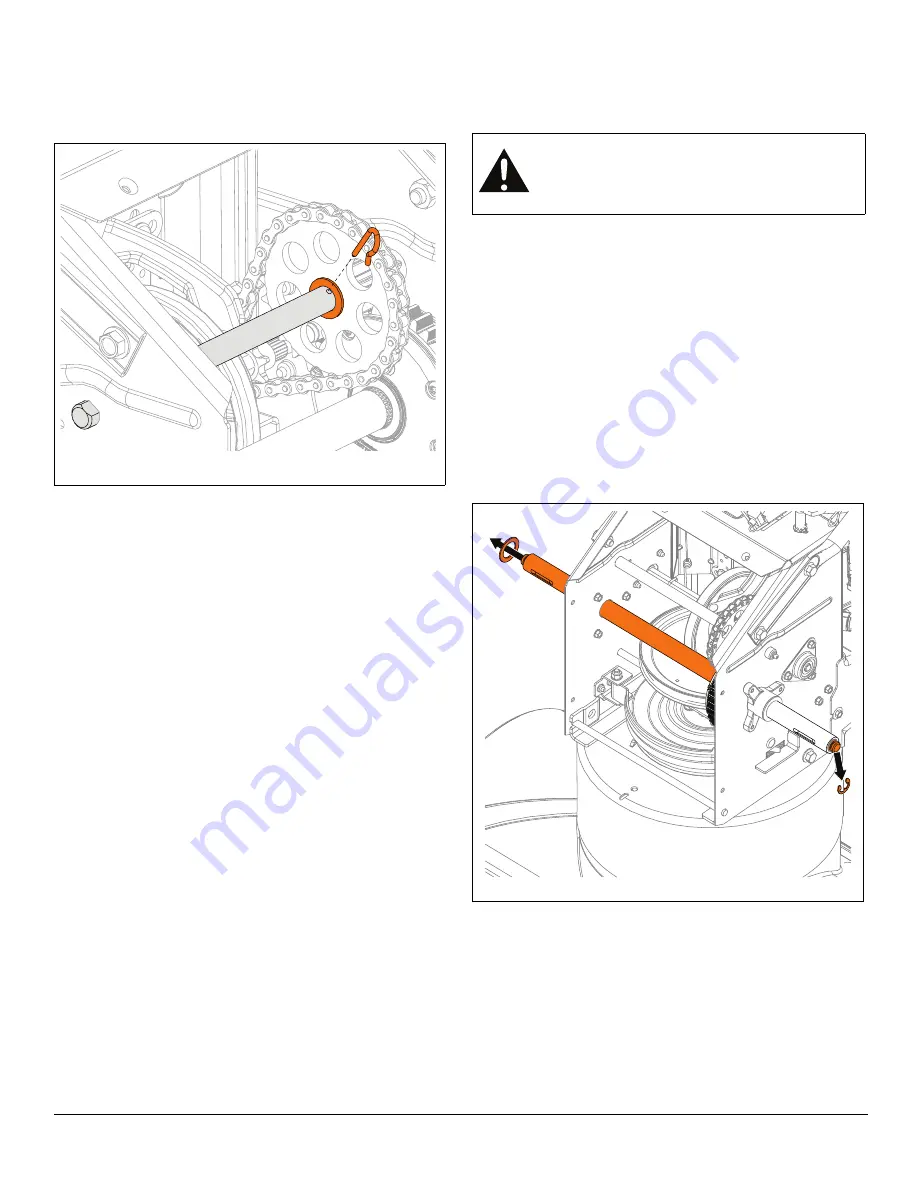

Figure 101

WARNING:

AVOID INJURY. Before placing unit

in service position, drain fuel from tank and fuel

system. See

Ensure unit is secure and will not tip.

Figure 102