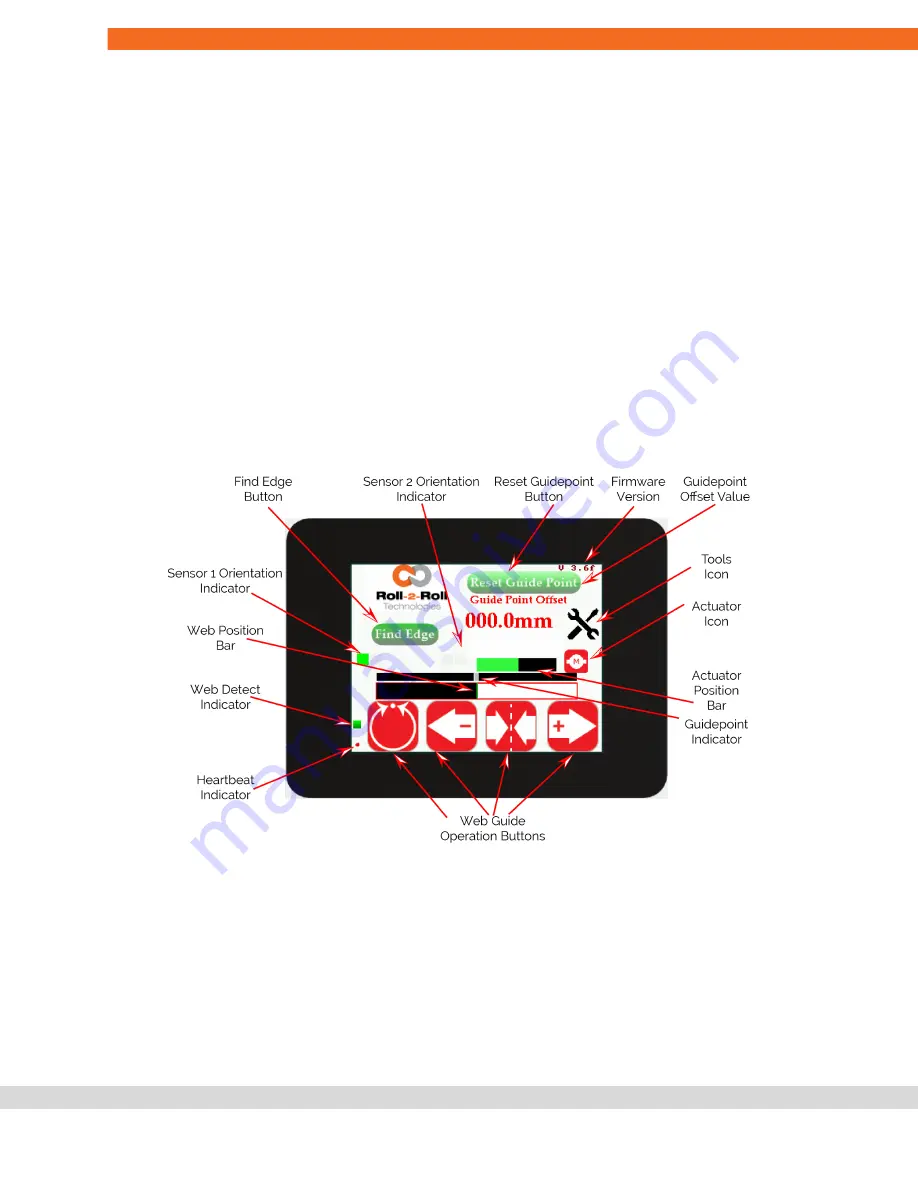

OPERATION AND OPERATOR INTERFACE

Main Operator Interface Screen

The main operator screen provides relevant information and operator access for both the sensing and

guiding application. The web guiding operations are accomplished using the web guide operation buttons on

the bottom of the screen.

The capacitive touchscreen on the SCU5 controller uses a language independent icon based screen that

allows ease of operation.

Never use sharp or pointed tools of any kind to operate the interface. Best practice is to have operators use

their fingers to press the different icons. Care must be taken to clean the touch screen surface periodically.

Its icon based design allows for a language independent operation without the need of translation of the

screen for setup and operation in different countries.

Heartbeat Indicator

A round indicator at the bottom left of the operator interface indicates the heartbeat or the communication

between the electronic controller board and the operator interface.

●

This indicator is used for troubleshooting purposes.

●

During normal operation this indicator will toggle between red and green at about 1 Hz.

NOTE:

Slow heartbeat may indicate communication delay between the main motherboard and the

touchscreen display/operator interface.

Content subject to change without notice

SCU5: Sensor and Web Guide Controller User Manual v 3.6| Page 15

Copyright © 2021 Roll-2-Roll Technologies LLC

+1-888-290-3215