Training Manual FAST EVO X/FLUENDO PLUS LNX -FAST EVO R X/BRD LNX

Page. 35 di 64

2.

Unscrew the screw “a” and insert the manometer connection pipe into the pipe tap

3.

Open the gas valve

4.

Press “on/off” button the display will show

5.

Press “+” and “-” buttons for 3 seconds, display shows ”PA”

6.

Press “+” button, to select ”Pd”. Open sanitary hot water tap

7.

Press the “on/off” button to access to the “Pd”, appliance is forced to run at max power

8.

On the manometer verify the pressure and if necessary by “+” or”-” to adjust as indicated in the gas

setting table

9.

Press the on/off button to exit from the parameter Pd. Close water tap

10.

Press + button to select the

parameter

11.

Press on/off button to save the change

4.3.2 FAST EVO X/FLUENDO PLUS LNX

4.3.2.1 MEASURE OF THE GAS PRESSURE

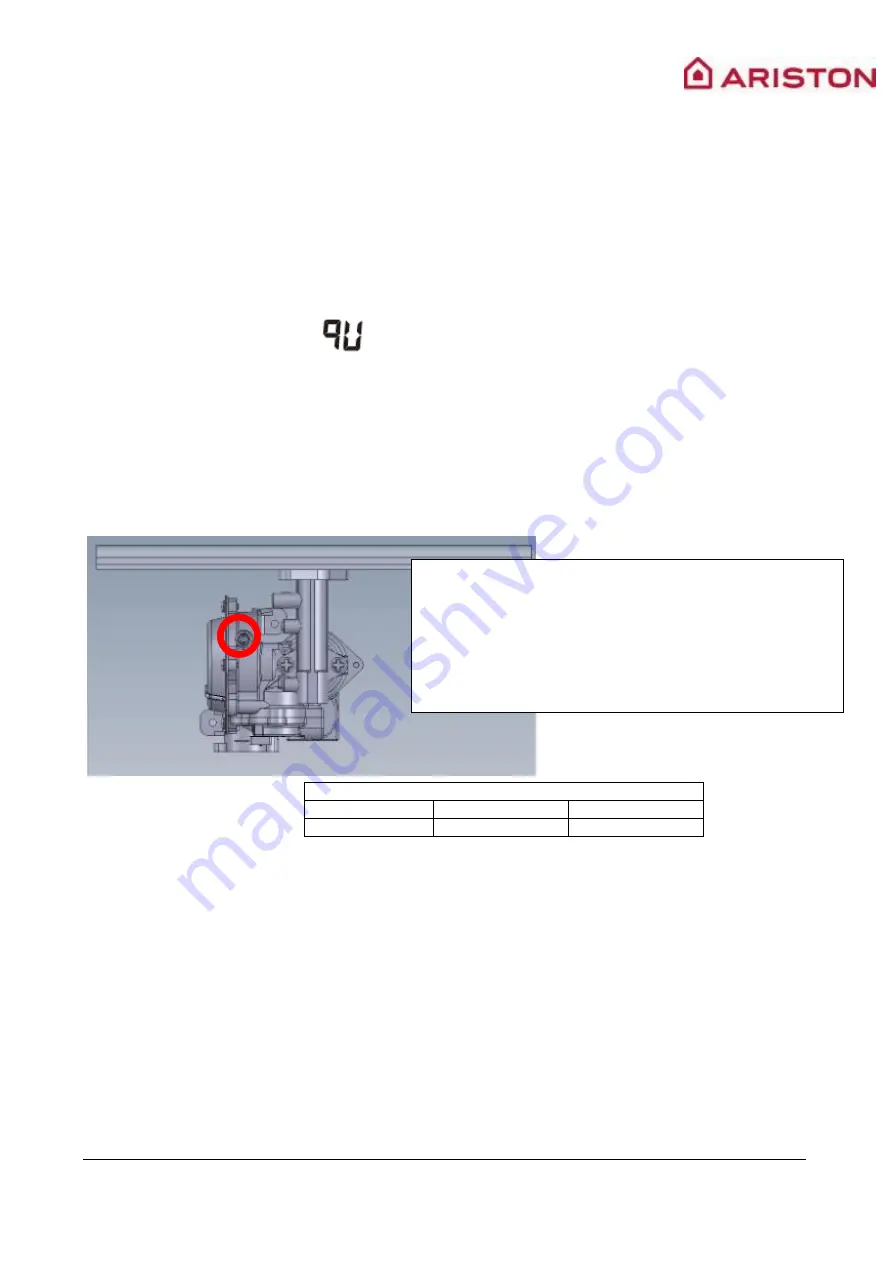

4.3.2.2 setting the micro-switch

INLET PRESSURE GAS

GAZ NATUREL

BUTHANE G 30

PROPANE G 31

20 mbar

29 mbar

37 mbar

Supply pressure check

1

.

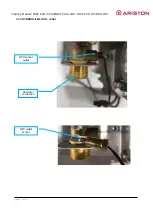

Unscrew the screw “b” and insert the pressure gauge fitting pipe

in the pressure intake.

2

. Put the unit at the maximum operating conditions (T° and water

flow). The outlet pressure must correspond to the gas type as

indicated on the table below.

3

. After

checking tighten screw “b” and check the seal.

b

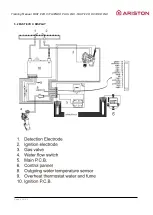

Summary of Contents for BRD LNX

Page 44: ...Training Manual FAST EVO X FLUENDO PLUS LNX FAST EVO R X BRD LNX Page 44 di 64 ...

Page 62: ...Training Manual FAST EVO X FLUENDO PLUS LNX FAST EVO R X BRD LNX Page 62 di 64 ...

Page 63: ...Training Manual FAST EVO X FLUENDO PLUS LNX FAST EVO R X BRD LNX Page 63 di 64 ...

Page 64: ...Training Manual FAST EVO X FLUENDO PLUS LNX FAST EVO R X BRD LNX Page 64 di 64 ...