57 / GB

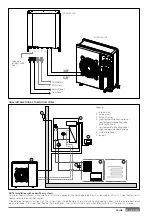

GAS CONNECTIONS BETWEEN INTERNAL UNIT

AND EXTERNAL UNIT

ATTENTION

Electrical connections are made after completing all hydraulic

and gas connections.

WARNING:

Device contains refrigerant fl uid. Leaving fl uid can cause scalds.

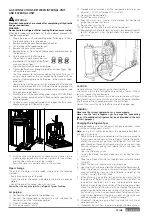

When both indoor and outdoor units shall be placed, proceed with

the pipes connections.

1. Shape the pipes by hand avoiding pipes fl attening or kinking.

Avoid unnecessary turns and bends.

2. Remove protective caps from copper tube ends.

3. Cut the tube to the requested length.

4. Remove the burrs with a reamer.

5. Remove fl are nuts from the unit connections and place them on

the tube end.

6. Flare the tube with the fl aring tool.

(Flare end must not have any burrs or

imperfections. The length of the fl ared

walls must be uniform.)

7. Align the centers of the connecting pipes.

8. Tighten the fl are nut as strong as possible with your fi ngers. Tigh-

ten it with torque wrench.

Use two spanners to unscrew or tighten the valve fl are nut. If

using a single spanner, the nut cannot be tightened with the

necessary tightening torque. Fix the pipes to the wall with hooks

or conduits.

(Be sure to tighten the valves (A) with a torque of 30 Nm and the

cap (B) with a torque of 5 Nm. Insuffi

cient tightening torque will

cause gas leaks. Applying excessive torque may damage the tube

fl aring and cause gas leaks.)

9. Evacuate the air in the connecting pipes using a VACUUM PUMP.

(For the vacuum pump, check oil is fi lled up to the specifi ed line

of the oil gauge).

10. Check gas leaks at connected points and open the fl are valves

allowing the gas to fi ll the entire system.

A

A

B

11. Wrap the valves and pipes with anti-condensate insulation, or use

pipes already provided with insulation. Tighten with tape, without

exerting too much pressure on the insulation.

Repair and cover any possible cracks in the insulation.

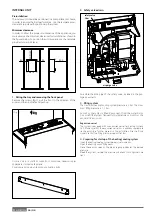

Pipes storage

The end of the pipes must be sealed using one of the following

methods:

•

Apply a cap to the end of the tube

•

Pinch the end of the copper pipe closed and braze any opening

closed

•

Cover the end of the copper pipe with vinyl tape

Remember the key principles for refrigerant pipes handling

Air purging

1) Connect the charge hose to the outdoor unit.

2) Connect the charge hose to the vacuum pump and keep the

control valves in the fully closed position.

3) Open LO handle completely.

4) Turn on the vacuum pump.

5) Proceed with evacuation until the compound pressure gauge

indicates -101 kPA (after about 15 minutes).

6) Close LO handle completely.

7) Turn off the vacuum pump.

8) Keep this status for 2 minutes while checking that compound

gauge’s pointer does not return.

9) Detach the vacuum pump.

10) Tightly secure the valve and caps of the service port.

11) Replace caps and check for leaks by using a leak detector specifi c

for HFC refrigerants. After the leak check, fully open the three-

way valve.

CAUTION:

Do not discharge the refrigerant gas to the atmosphere.

Use a vacuum pump to discharge the air remained in the set. If the air

remains, the capacity may decrease.

For what concerns the vacuum pump, be sure to use one with back-

fl ow preventive function so that the oil in the pump does not backfl ow

into the pipe of the air conditioner when the pump stops.

Connect the vacuum pump to the fl are valve of the bigger pipe.

WARNING:

Never use the system compressor as a vacuum pump.

Never use the unit refrigerant gas to purge the connecting

pipes. (No additional refrigerant has been provided in the unit

for this purpose).

Charging the refrigerant gas

Before proceeding with the refrigerant charging operations, check

that all the valves and cocks are shut.

Note:

during initial installation, perform the procedure described in

paragraph “Air purging”.

1. Connect the low pressure connection of the pressure gauge to

the service valve, and connect the refrigerant tank to the central

inlet of the pressure gauge. Open the refrigerant tank and then

open the cap on the central valve and work the pin valve until you

hear the refrigerant exiting, then release the pin and screw the

cap back on;

2. Open the three-way valves;

3. Turn on the device in cooling mode. Leave it running for a few

minutes;

4. Place the refrigerant canister on the electronic scales and record

its weight;

5. Check the pressure shown on the pressure gauge;

6. Open the “LOW” knob and allow the refrigerant to fl ow gradually;

7. When the refrigerant charge in the circuit reaches the specifi ed

value (calculated by means of the difference in weight of the

canister), shut off the “LOW” knob;

8. When charging is complete, test operation by measuring the

temperature of the gas pipe with the special thermometer. The

temperature should be 1 to 8°C over the temperature read on

the evaporation temperature section of the pressure gauge. Now

check the stability of the pressure, by connecting the pressure

gauge assembly to the three-way service valve. Open the three-

way valve fully, turn on the device and check for refrigerant leaks

using the leak detector (if there are any leaks, carry out the pro-

cedure described in paragraph “Refrigerant recover”);

9. Disconnect the pressure gauge from the valve and turn the air

conditioning unit off;

10. Disconnect the tank from the pressure gauge and close all caps.

Summary of Contents for 3300919

Page 8: ...8 IT 1106 383 1016 670 ø 10 374 1506 383 1016 670 ø 10 374 70 S 70 S T EXT 9 0 110 S T EXT ...

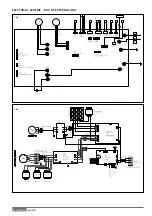

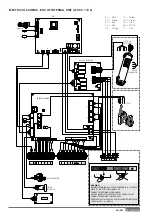

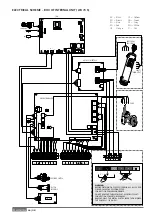

Page 22: ...22 IT SCHEMA ELETTRICO QUADRO UNITÀ ESTERNA 3 ph 1 ph ...

Page 50: ...50 GB 1106 383 1016 670 ø 10 374 1506 383 1016 670 ø 10 374 70 S 70 S T EXT 90 110 S T EXT ...

Page 64: ...64 GB 3 ph 1 ph ELECTRICAL SCHEME BOX OF EXTERNAL UNIT ...

Page 86: ...86 IT ...

Page 87: ...87 IT ...