82 / GB

MAINTENANCE

Maintenance is an essential operation to insure safety, correct

working and duration of life of the appliance.

It must be carried out in accordance with the regulations in force.

It is requested to check periodically the pressure of the refrigerant

gas. Before proceeding with maintenance:

• Disconnect the power supply from the appliance

• Close the water taps of the heating circuit

General remarks

It is necessary to perform at least once a year the following checks:

1. Visual control of the general state of the system.

2. Check for leakage of the hydraulic circuit and possible replace-

ment of the seals.

3. Tightness of the circuit of the refrigerant gas.

4. Check the functioning of the heating safety tools (thermostats).

5. Overall control of the functioning of the appliance.

6. Check the pressure on the heating circuit.

7. Check the pressure of the expansion vessel

8. Keep clean the front grille and the outdoor unit battery pack.

ATTENTION

Empty the components that may contain residual hot water befo-

re manipulating them.

Remove limestone deposits from the components, following the

instructions on the descaling agent used.

Do this in a ventilated room, wearing the necessary safety devices,

avoid mixing of chemical products and protecting the equipment

and surrounding objects.

Information for the user

Inform the user on how the installed appliances work.

In particular, provide the user with the instruction manual, infor-

ming him of the need to keep the booklet close to the appliance.

Also, inform the user of the need to proceed with the following

actions:

• Periodically check the water pressure

• Pressurize the system, when necessary providing an adequate

air purge

• Adjust the parameters setting and devices in order to obtain a

better functioning and a more economical management of the

system

• Subcontract, as provided by the rules, periodic maintenance

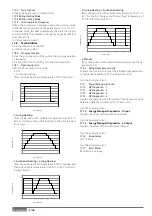

Antifreeze function

The system has a frost protection.

Frost protection of the external unit : the primary circulator of the

internal unit is switched on if the return water temperature to the

external unit is equal to or less than 7 ° C for more than two con-

secutive minutes. If the water temperature reaches and exceeds

8 ° C for more than two consecutive minutes, the pump is turned

off . In the case of return temperature probe failure, the function

refers to the values of the fl ow temperature probe.

In the case in which the antifreeze function of the external unit is

not suffi cient, the frost protection of the internal unit will be au-

tomatically activated. Also in this case the primary circulator of the

internal unit is switched on if the return water temperature to the

external unit is less than or equal to 7 ° C for more than two con-

secutive minutes. If the water temperature reaches and exceeds

9 ° C for more than two consecutive minutes, the pump is turned

off . In the case of return temperature probe failure, the function

refers to the values of the fl ow temperature probe.

In case of the circulation of water provided by the main pump is

still not suffi cient to ensure a frost protection, the system will au-

tomatically manage the ignition of the entire external unit and of

the electrical resistances .

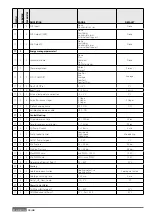

Summary of Contents for 3300919

Page 8: ...8 IT 1106 383 1016 670 ø 10 374 1506 383 1016 670 ø 10 374 70 S 70 S T EXT 9 0 110 S T EXT ...

Page 22: ...22 IT SCHEMA ELETTRICO QUADRO UNITÀ ESTERNA 3 ph 1 ph ...

Page 50: ...50 GB 1106 383 1016 670 ø 10 374 1506 383 1016 670 ø 10 374 70 S 70 S T EXT 90 110 S T EXT ...

Page 64: ...64 GB 3 ph 1 ph ELECTRICAL SCHEME BOX OF EXTERNAL UNIT ...

Page 86: ...86 IT ...

Page 87: ...87 IT ...