7

GB

Duplicate Data Plate

Where the data plate is obscured by cabinetry when

the cooker is in the installed position, place a

duplicate data plate on a surface of the cabinetry

adjacent to the cooker.

Adapting to different types of gas

It is possible to adapt the appliance to a type of gas

other than the default type (this is indicated on the

rating label on the cover).

Adapting the hob

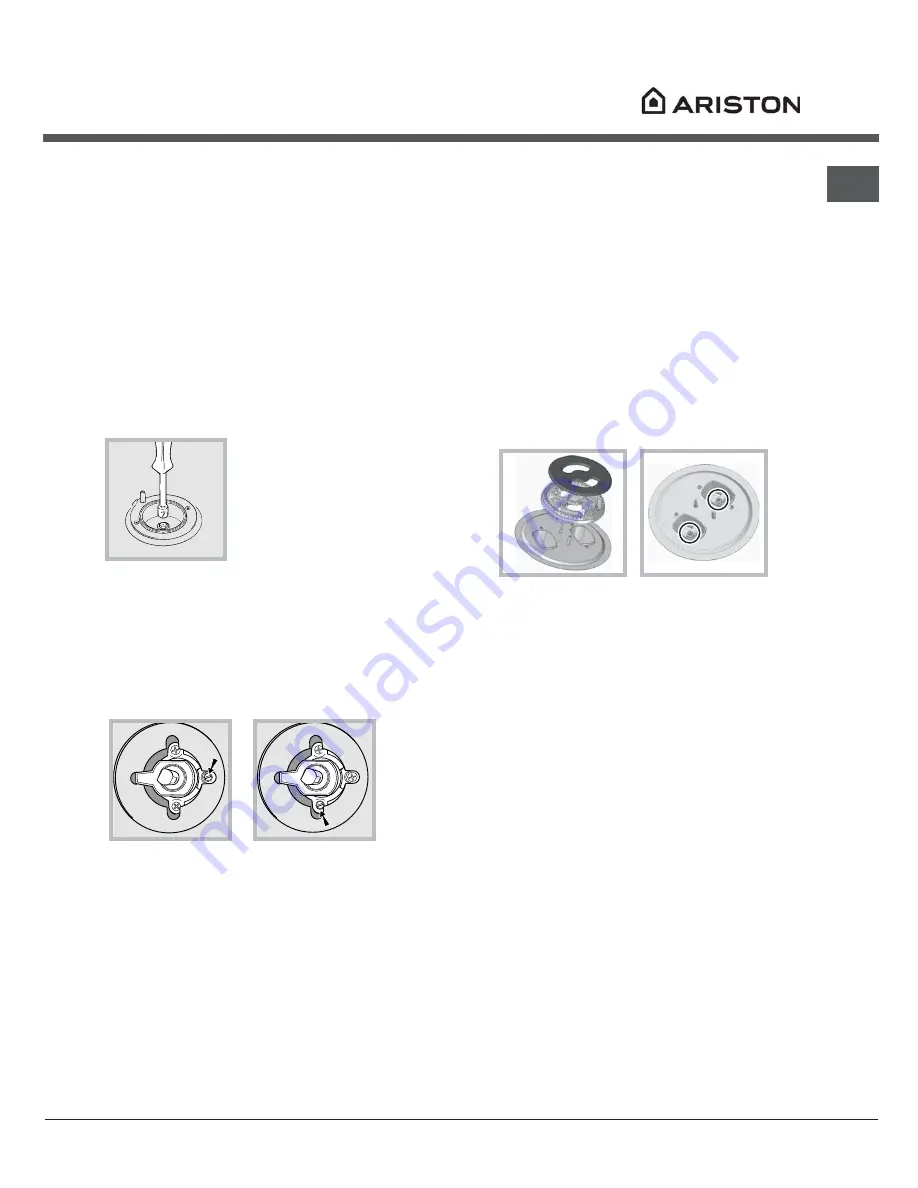

Replacing the nozzles for the hob burners:

1. Remove the hob grids and slide the burners off

their seats.

2. Unscrew the nozzles using

a 7 mm socket spanner (

see

figure), and replace them with

nozzles suited to the new type

of gas

3. Replace all the

components by following the

above instructions in reverse.

Adjusting the hob burners’ minimum setting:

1. Turn the tap to the minimum position.

2. Remove the knob and adjust the regulatory

screw, which is positioned inside or next to the tap

pin, until the flame is small but steady.

!

If the appliance is connected to a liquid gas

supply, the regulatory screw must be fastened as

tightly as possible:

3. While the burner is alight, quickly change the position

of the knob from minimum to maximum and vice versa

several times, checking that the flame is not

extinguished.

!

The hob burners do not require primary air adjustment.

!

After adjusting the appliance so it may be used with a

different type of gas, replace the old rating label with a

new one that corresponds to the new type of gas (these

labels are available from Authorised Technical Assistance

Centres).

!

Should the gas pressure used be different (or vary

slightly) from the recommended pressure, a suitable

pressure regulator must be fitted to the inlet hose in

accordance with current national regulations relating

to “regulators for channelled gas”.

Replacing the Triple ring burner nozzles

1. Remove the pan supports and lift the burners out of

their housing. The burner consists of two separate

parts (see pictures).

2. Unscrew the nozzles using a 7 mm socket spanner.

Replace the nozzles with models that are configured

for use with the new type of gas (see Table 1). The two

nozzles have the same hole diameter.

3. Replace all the components by completing the above

operations in reverse order.

• Adjusting the burners’ primary air :

Does not require adjusting.

• Setting the burners to minimum:

1. Turn the tap to the low flame position.

2. Remove the knob and adjust the adjustment screw,

which is positioned in or next to the tap pin, until the

flame is small but steady.

3. Having adjusted the flame to the required low setting,

while the burner is alight, quickly change the position

of the knob from minimum to maximum and vice versa

several times, checking that the flame does not go out

4. Some appliances have a safety device (thermocouple)

fitted. If the device fails to work when the burners are

set to the low flame setting, increase this low flame

setting using the adjusting screw.

5. Once the adjustment has been made, replace the seals

on the by-passes using sealing wax

!

If the appliance is connected to liquid gas, the regulation

screw must be fastened as tightly as possible.

!

Once this procedure is finished, replace the old rating

sticker with one indicating the new type of gas used.

Stickers are available from any of our Service Centres.

!

Should the gas pressure used be different (or vary

slightly) from the recommended pressure, a suitable

pressure regulator must be fitted to the inlet pipe (in order

to comply with current national regulations).