AUS

5

adequate for a sufficient supply to the appliance

when all the burners are lit

Duplicate Data Plate

Where the data plate is obscured by cabinetry when

the cooker is in the installed position, place a

duplicate data plate on a surface of the cabinetry

adjacent to the cooker.

Adapting to different types of gas

To adapt the hob to a different type of gas other than

default type (indicated on the rating plate at the base of

the hob or on the packaging), the burner nozzles should

be replaced as follows:

1. Remove the hob grids and slide the burners off their

seats.

2. Unscrew the nozzles using a 7 mm socket spanner,

and replace them with nozzles for the new type of gas

(see table 1 “Burner and nozzle characteristics”).

3. Reassemble the parts following the above procedure in

the reverse order.

4. Once this procedure is finished, replace the old rating

sticker with one indicating the new type of gas used.

Sticker are available from any of our Service Centres.

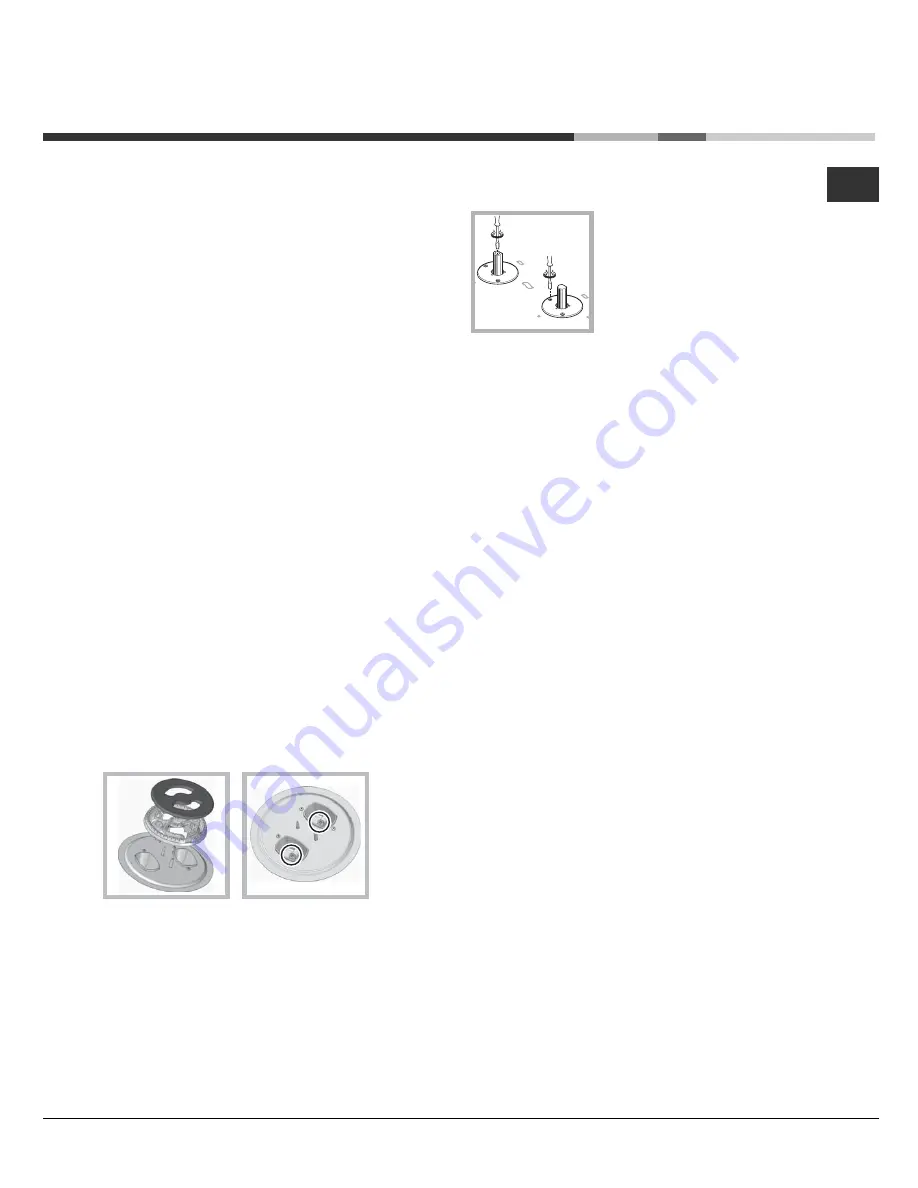

Replacing the Triple ring burner nozzles

1. Remove the pan supports and lift the burners out of

their housing. The burner consists of two separate parts

(see pictures).

2. Unscrew the nozzles using a 7 mm socket spanner.

Replace the nozzles with models that are configured

for use with the new type of gas (see Table 1). The two

nozzles have the same hole diameter.

3. Replace all the components by completing the above

operations in reverse order.

• Adjusting the burners’ primary air :

Does not require adjusting.

• Setting the burners to minimum:

1. Turn the tap to the low flame position.

2. Remove the knob and adjust

the adjustment screw, which is

positioned in or next to the tap

pin, until the flame is small but

steady.

3. Having adjusted the flame to the required low setting,

while the burner is alight, quickly change the position of

the knob from minimum to maximum and vice versa

several times, checking that the flame does not go out.

4. Some appliances have a safety device (thermocouple)

fitted. If the device fails to work when the burners are

set to the low flame setting, increase this low flame

setting using the adjusting screw.

5. Once the adjustment has been made, replace the seals

on the by-passes using sealing wax or a similar

substance.

!

If the appliance is connected to liquid gas, the regulation

screw must be fastened as tightly as possible.

!

Once this procedure is finished, replace the old rating

sticker with one indicating the new type of gas used.

Stickers are available from any of our Service Centres.

!

Should the gas pressure used be different (or vary

slightly) from the recommended pressure, a suitable

pressure regulator must be fitted to the inlet pipe (in order

to comply with current national regulations).

Post Installation Checks

Perform post installation checks and ensure proper

and safe operation before leaving. Test all burners

individually and in combination.

Leak Check

• Ensure all gas control knobs are in the Off

position.

• Ensure the gas supply is switched on.

• Spray a solution of soapy water onto all gas joints

as well as the full length of any flexible hoses.

UNDER NO CIRCUMSTANCES USE A NAKED

FLAME IN CHECKING FOR LEAKS.

If bubbles appear anywhere, turn the gas supply off,

check all connections and retest. If satisfactory

operation cannot be achieved, contact place of

purchase or their appointed agent for service.

Flame check

Turn each burner on, and ensure that the flame is

blue with minimal yellow tipping. If there is

significant yellow tipping, flame lift off or excessive