LEAKAGE FROM THE NOZZLE

This occurs when the Needle Packing Nut 10-2086 is

too tight

compressing the

Needle Packing 10-2085 too tightly around the needle.

Half fill the cup with water. Attach the gun to the hose and turn on the turbine

blower to pressurize the cup. Pull the trigger and release. Check the nozzle for

water spurting out.

Use the supplied wrench to

GENTLY

loosen the nut (1 or 2 degrees only at a time).

This is a very sensitive adjustment.

Again pull the trigger and release. Wipe away

the water in between adjustments. Repeat until no water is seen at the nozzle hole.

LEAKAGE FROM THE NEEDLE PACKING NUT

This occurs when the needle packing nut is

too loose

.

Half fill the cup with water. Attach the gun to the hose and turn on the turbine

blower to pressurize the cup. Use the supplied wrench to

GENTLY

tighten the

needle packing nut 1 or 2 degrees only.

This is

a very sensitive adjustment.

Wipe

away the water in between adjustments. Repeat until no water is seen where the

needle passes through the Needle Packing Nut 10-2086.

It is a good idea to apply light machine oil or Vaseline to the needle shaft where

it passes through the needle packing nut and work it in and out by pulling the

trigger back and forth. This will lubricate the Needle Packing 10-2085.

QTech

HVLP Turbine

Needle Packing Nut

18

Aristospray

.com

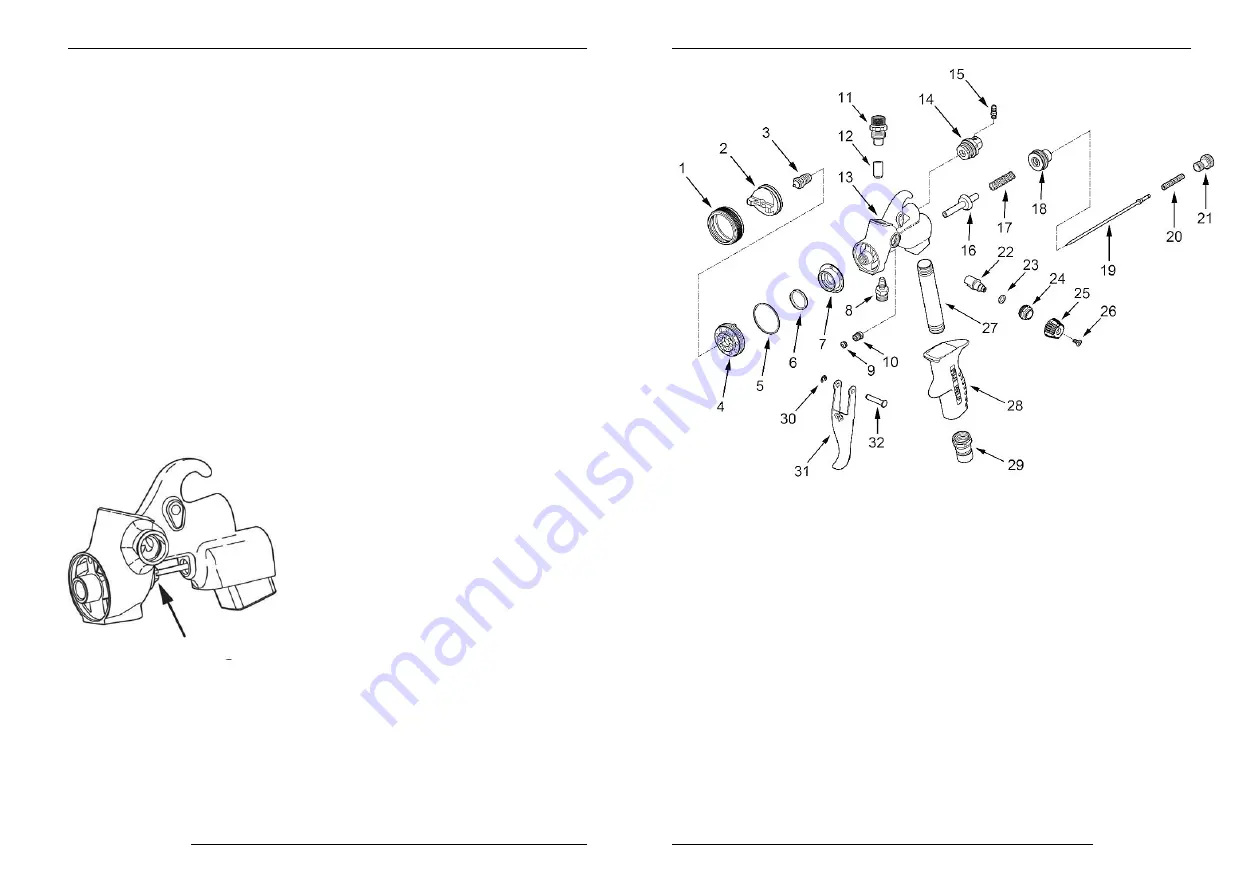

ITEM PART

DESCRIPTION

1

10-2080

Collar

2

N/A

Air Cap

2

3

N/A

Fluid Nozzle

2

4

10-2081

Air Diffuser

5

10-2082

Diffuser Seal

6

10-2083

Air Divider Seal

7

10-2084

Air Divider

8

N/A

Suction Fluid Coupler

1

9

10-2085

Needle Packing

10

10-2086

Needle Packing Nut

11

N/A

Gravity Fluid Coupler

1

12

N/A

Fluid Coupler Seal

1

13

N/A

Gun Body

14

10-2087

Rotating Nipple Assembly

15

10-2088

Nipple

16

10-2089

Spindle Valve

Parts marked with

1

are not removable

Parts marked with

3

are available in Kit 10-2097

ITEM PART DESCRIPTION

17

10-2090

Valve Spring

18

10-2091

Fluid Screw Nut

19

N/A

Needle

2

20

10-2092

Needle Spring

21

10-2093

Fluid Adjusting Knob

22

N/A

Air Deflector

3

23

N/A

Deflector Seal

3

24

N/A

Control Knob Nut

3

25

N/A

Pattern Control Knob

3

26

N/A

Locking Screw

3

27

N/A

Handle Tube

1

28

N/A

Handle

1

29

N/A

Hose Connector

1

30

10-2094

Retaining Ring

31

10-2095

Trigger

32

10-2096

Trigger Pin

Parts marked with

2

refer to page 10

19