TURBINE CARE & MAINTENANCE

FILTERS

It is important to clean or replace the filters regularly. Operating the turbine unit

with clogged or dirty filters will cause the turbine to overheat and result in premature

failure. QTech HVLP Turbines have either one or

two filters. To remove, simply pull

the filters out from filter enclosure. Wash in warm soapy water and dry before

replacing.

All QTech filters are a friction fit. The filter must fill the entire filter enclosure.

Cleaning your filters regularly is essential to maintaining your QTech HVLP

Turbine. It is always a good idea to have a spare pair of filters on hand.

Re-order number for filter: 10-2049 (pack 2)

IMPORTANT NOTE

All QTech HVLP Turbines are designed for intermittent use. When taking a

break between coats or stepping aside to refill your cup, it’s good practice to turn the

machine off during this time. This allows it to cool off.

When spraying, always ensure that the turbine unit is at least 5.0m (15 feet)

away from spray project and in a well ventilated area. This will prevent any

overspray or debris being ingested into the turbine. Failure to do this may cause

the filters to clog, resulting in damage to the internal motor.

It is a good idea to make use of the Turbine Wireless Remote 10-2018 (110 volt

only). This device allows you to turn the turbine unit on/off at your convenience

without having to walk back and forth to the turbine.

If you experience a problem with your turbine unit, please

DO NOT

try to open

and service the turbine yourself. Contact your approved dealer or Aristospray for

technical assistance. If it is an issue of no power, check your power outlet. Also,

try re-setting the breaker on the back of the turbine by pressing it once.

QTech

HVLP Turbine

20

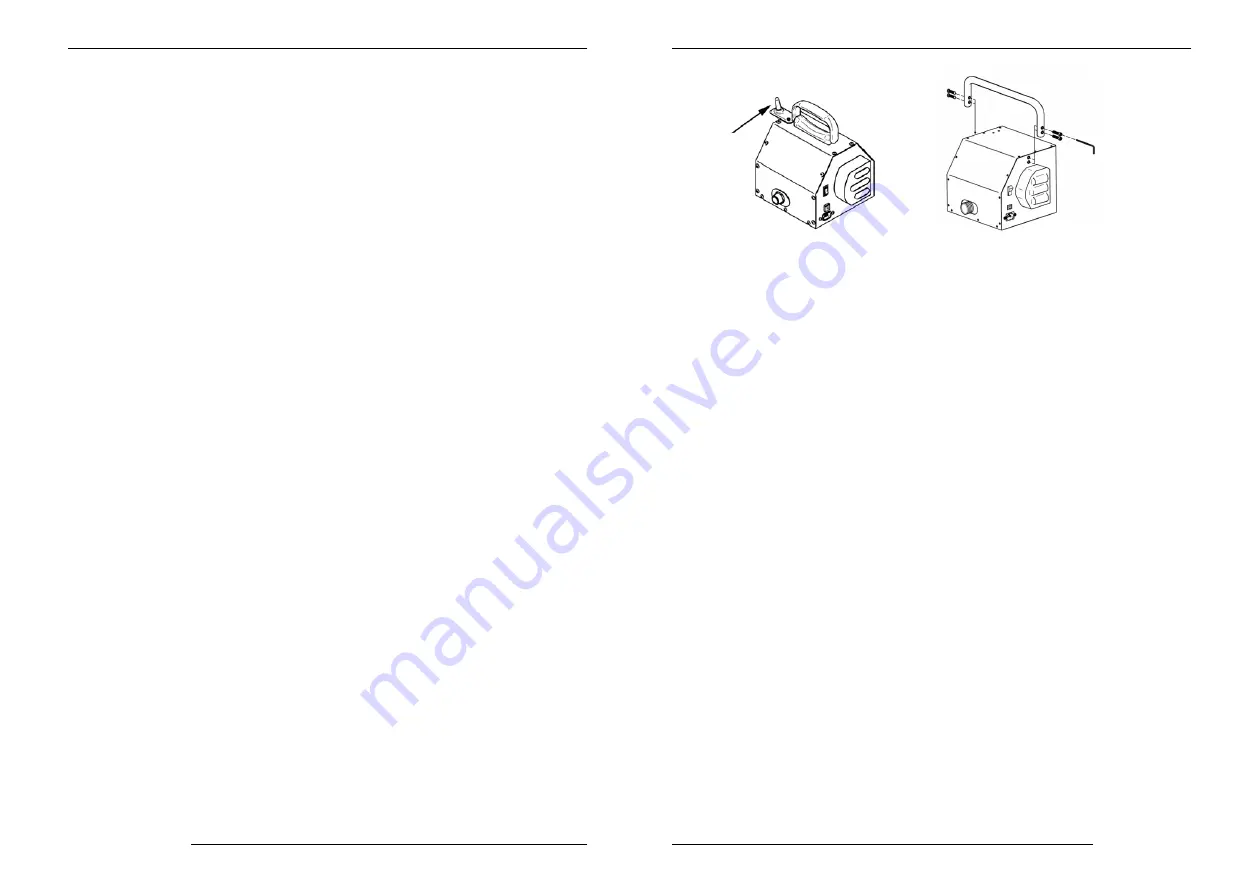

GUN HOLDER & HANDLE BAR

GUN HOLDER INSTALLATION

The two holes on the top of the holder require the two machine screws and

washers. These screws fit into threaded inserts in the metal case.

Do not over tighten - snug is fine.

The single silver-colored screw must be installed to the single hole on the

side of the gun holder. Once again, please do not over tighten this screw -

snug is fine.

If you do not intend on using the gun holder you may insert the appropriate

screws (as mentioned above) to block the holes.

TURBINE HANDLE BAR INSTALLATION

Included in the box is an Allen key with four black screws and handle bar.

Carefully position and align the handle bar over the four holes - two on each side

of the turbine case. Using the Allen key, secure the screws through the handle bar

onto the turbine case.

GUN HOLDER USE

Place the Hose Connector (base of the gun handle) over the shaft of the gun holder

as shown in above illustration. Please ensure it is fully set down to the base of the

shaft. The spray gun will now sit stationary. The gun can be left on the holder for

any length of time. It is a convenient resting place between spraying and ideal for

filling the gravity cup.

Aristospray

.com

Gun Holder

21