When planning the pellet store you should keep in mind that you cannot use the same

feeding system for a store designed for a day’s or a week’s supply as for a store desig-

ned for bulk deliveries. A common way is to start with a small and simple pellet store

which is a quick and simple solution. It demands a bit of handling however, both when

you pick up the pellets from your supplier and when you fi ll them into your store. For

this kind of store, pellets can be acquired in small sacks (normally between 6-20 kg) or

large sacks (normally between 500-1000 kg).

Th

e very best solution for a convenient and simple handling of pellets however is

to install a pellet store designed to accommodate pellets delivered by bulk tanker. Th

is

delivery method will demand a store of some 6 m

3

to accommodate 3 tons which is the

normal volume at bulk deliveries.

Th

e pellet store should be designed to eliminate the risk of contamination and

moisture penetration. Take special care to avoid damp penetration through the walls

and fl oor. It is also important that pellets are not exposed to direct contact with water

in the form of rain or condensation. Pellets do not however absorb moisture from

surrounding moist air and can therefore be stored outdoors as long as they are under

cover. Th

e fuel store should be planned according to your estimated consumption so

that refi lling and handling takes place at convenient intervals.

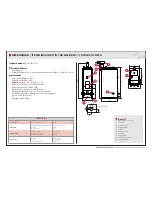

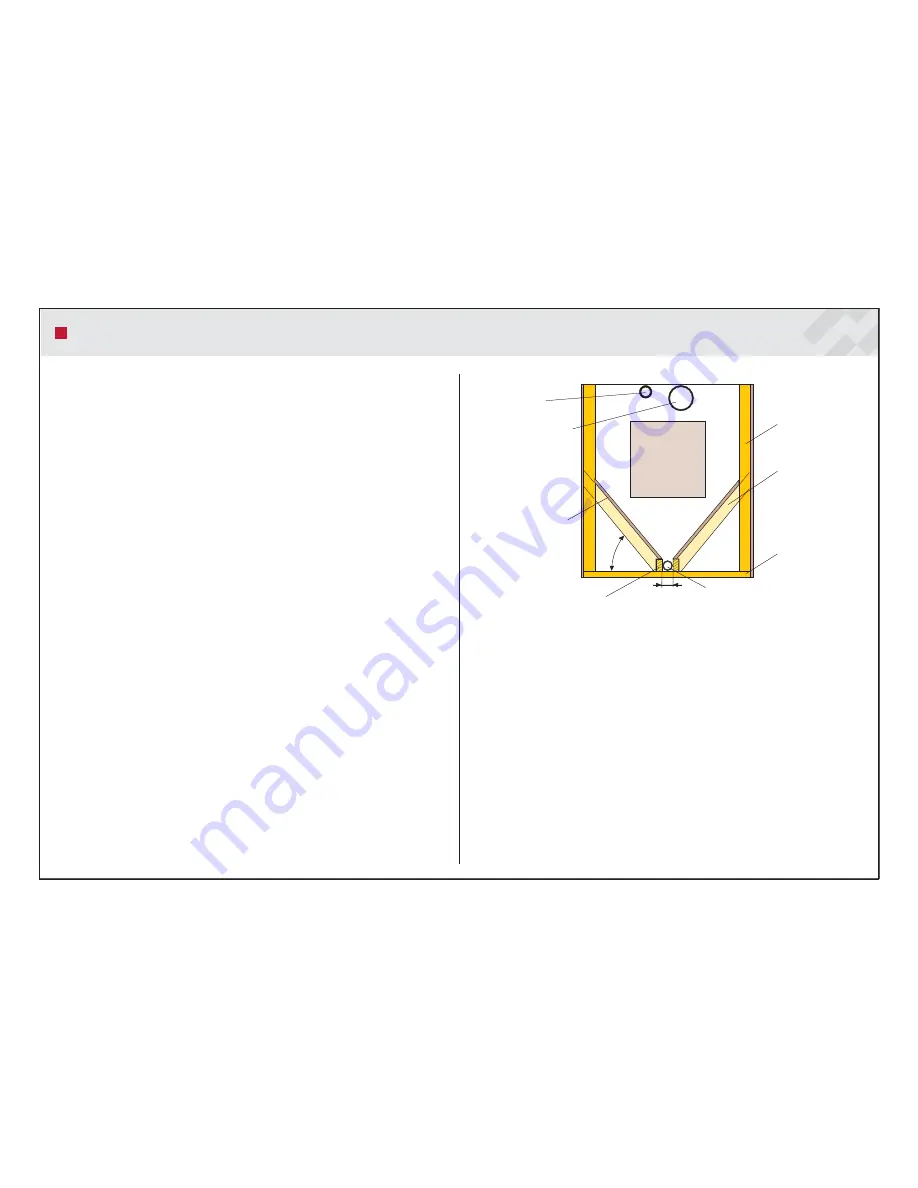

Inspection hatch

600 x 600 mm

Store pipe (delivered by Ariterm),

see previous page. The whole length

of the store pipe shall be supported.

2 x horizontal

studs 45x95 mm

50˚

80 mm

Bulk filling pipe

Ø 100 mm

Vent pipe Ø 200 mm

Attention!

If filter sack is used

for filling we

recommend

2 x Ø 200 mm

Vertical studs

95x45 mm

c/c 600 mm

Slippery plywood

board 16 mm

Horizontal stud

45x95 mm

Stud 45x95 mm

c/c 600 mm

The drawing represents a stand alone pellet storage bin. If the store is built

against a supporting wall, the sloping studs will have to be arranged differently.

ARITERM SWEDEN AB

Installation, Operation and Maintenance - 2007.10.26- 9/12

STORAGE PLANNING