20

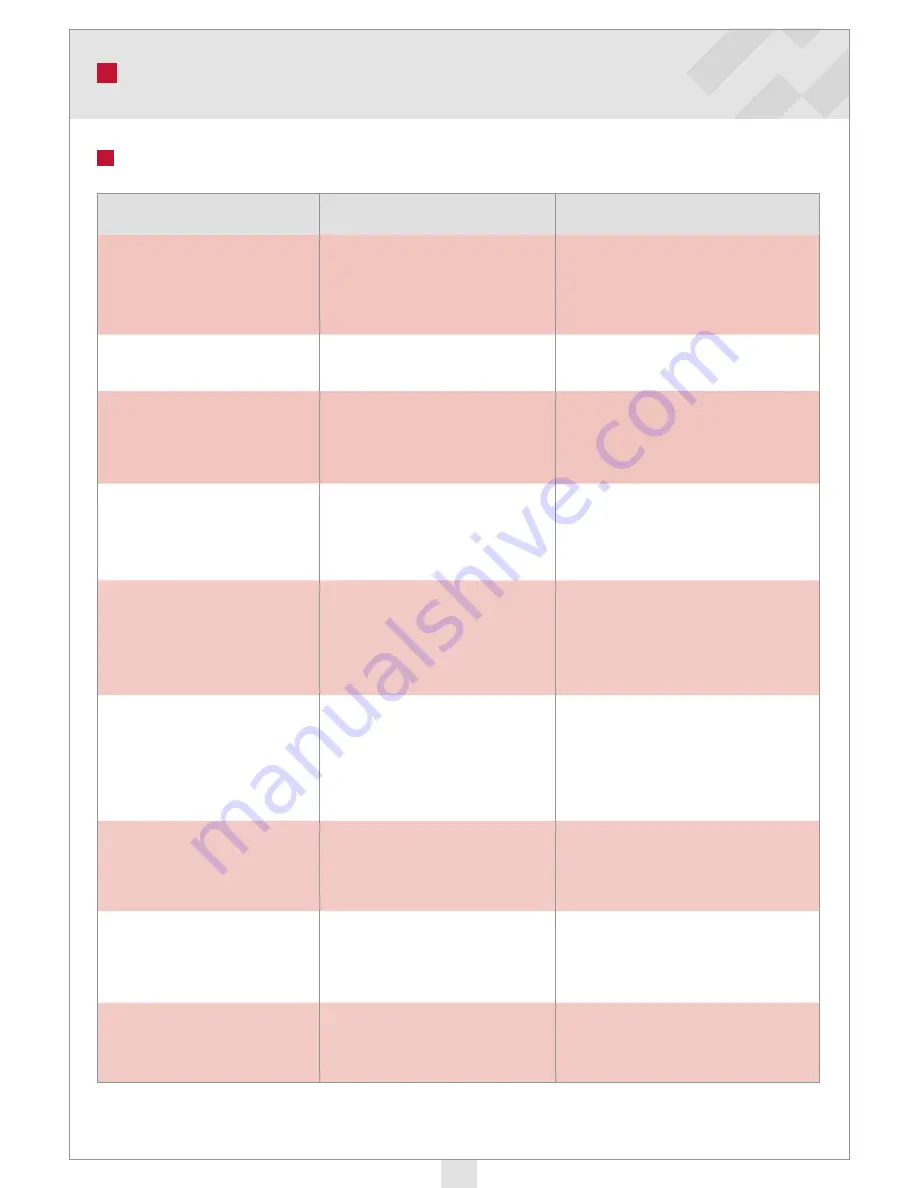

Malfunction

Cause

Action

The safety apparatus has

stopped the equipment.

The motor guard has tripped

owing to excessive resistance.

Remove the obstacle preventing mo-

vement of the auger by turning the

auger backwards and check that the

auger turns freely. Reset the alarm.

The motor guard has tripped due

to lack of phase.

Check the power supply. Reset the

alarm.

The boiler or burner head

overheat protection has tripped

as a result of boiler overheat.

Find out the reason for the

overheat Remove the causes of the

malfunction. Reset the overheat

protection. Reset the alarm.

The flame control thermostat

has tripped because the flue gas

temperature has fallen below the

settings value.

Check fuel feed: Restart the unit. If

necessary, reduce the flame control

thermostat settings value.

The burn back thermostat has

tripped because the surface

temperature of the auger pipe

has risen above the settings

value.

Find out the causes of the burn back.

Start up the unit if it is safe to do so.

If necessary, change the adjustment

values (e.g. the temperature of the

unit may cause a false alarm).

The AVTA valve has tripped due

to auger pipe overheat, and has

filled the intermediate tank with

water.

Drain the water out through the drain

hole in the bottom of the water tank.

Send the wet fuel through the burner

head to the ashbox. Feed dry fuel into

the burner head and start the unit.

The displacement limit has

tripped because the boiler or

burner auger has been displaced.

Remove excess fuel from the boiler

and burner. Check the pipe- and other

connections of the unit as well as the

operation of the flame control.

The limit switches of the hatches

have tripped because one of the

hatches was open.

Find out the reason for the tripping.

Shorten the discharger operating

time. Check the operation of the

intermediate tank photocell.

The flue gas extractor has

stopped.

Find out the cause of the malfunction,

in the power supply or the frequency

converter.

Instructions when malfunctions may arise

TROUBLE-SHOOTING

Summary of Contents for Multijet 500

Page 1: ...INSTALLATION OPERATION AND MAINTENANCE Multijet 500 1500 hydraulic ...

Page 25: ...25 HYDRAULIC DIAGRAM HTR Hydraulics Oy Multijet 500 1000 kW ...

Page 26: ...26 HTR Hydraulics Oy Multijet 1500 kW HYDRAULIC DIAGRAM ...

Page 38: ...38 DECLARATION OF COMFORMITY ...

Page 40: ...NOTES 40 ...

Page 41: ...41 NOTES ...

Page 42: ...42 NOTES ...

Page 43: ...43 NOTES ...