83

Results

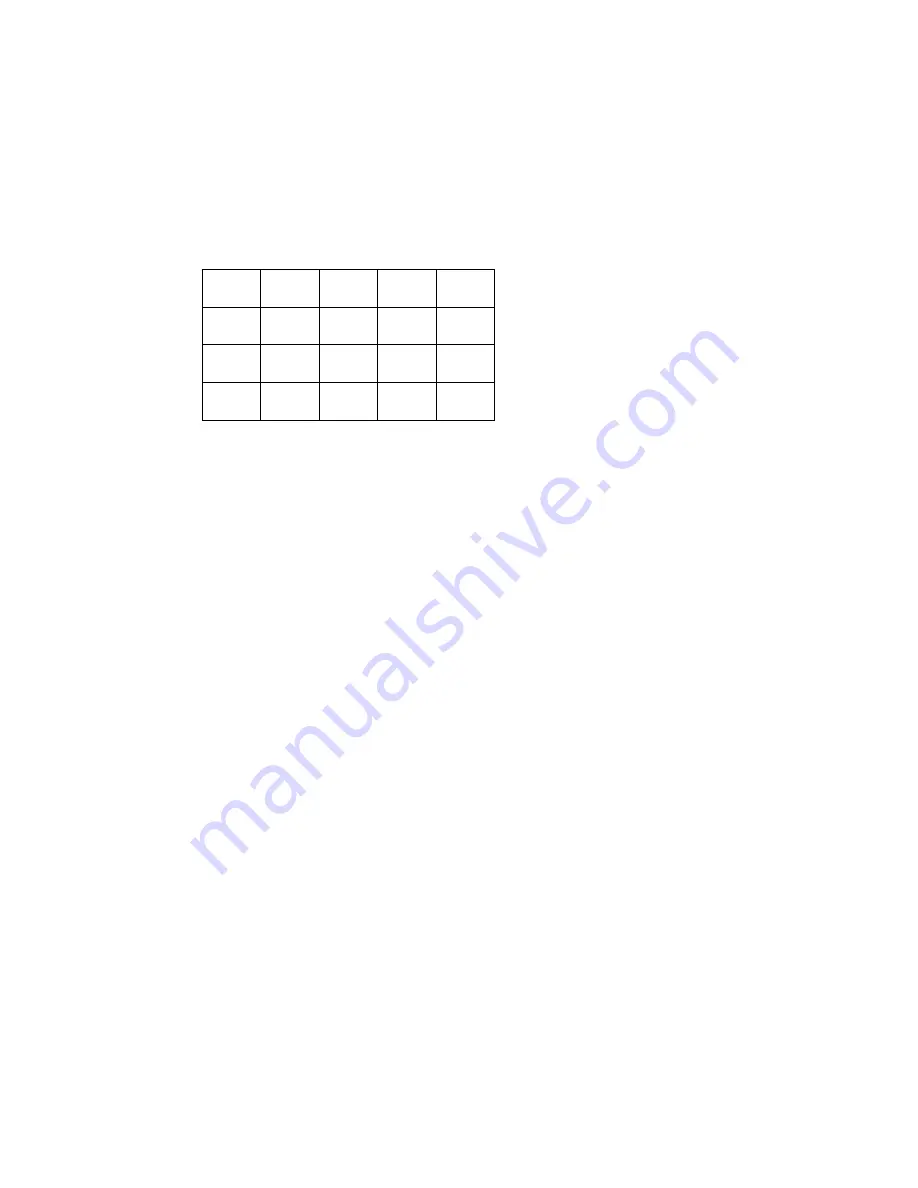

Tabulate your readings and calculations as follows:

Breadth of throat, b

=…………(m)

Height of throat, z

=…………(m)

Area of throat A

t

=………....(m

2

)

y

0

y

1

h

Q

C

d

Calculate the coefficient of discharge C

d

for the “blackwater” flow condition.

Plot the stage discharge characteristics.

Conclusion

What is the function of the deflecting nappe in the conduit?