Issue 1324

507120-01

Page 8 of 18

The air handler is provided with 3/4” NPT condensate drain

connections.

Sloping the Drain

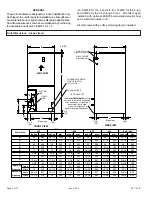

Make sure the unit is sloped (similar to the slope shown

in Figure 10) so that the drain pan will empty completely

without water standing in the pan.

Figure 10

Sloping the Drain

INSTALL CONDENSATE DRAIN

1. Remove the appropriate drain knockouts. If necessary,

remove the indoor coil assembly from the cabinet.

2. Connect primary drain line connection to the primary

drain pan connection. The primary drain connection is

flush with the bottom of the inside of the pan. Secondary

connection is raised above the bottom of the inside of

the pan.

NOTE:

When making drain fitting connections to the drain

pan, hand tighten the fitting and use a sealant. Over-

tightening the fittings can split connections on the drain pan.

3. If the auxiliary drain line is to be used, remove the plug

and route the drain line so that water draining from the

outlet will be easily noticed by the homeowner. The

auxiliary drain line does not required venting or a trap.

Refer to local codes.

4. After removal of drain pan plugs, check the drain port

to see if holes have been drilled. If not drilled, use a

19/32” bit to drill out the primary drain hole; use a 3/8”

drill bit for the secondary drain hole. Remove all drill

shavings.

5. Make sure drain ports and drain pan are free of all

debris.

6. Plug and check any unused drain pan openings for

tightness. Torque plugs to 30 in. lb. to prevent water

leaks or seepage from the drain pan.

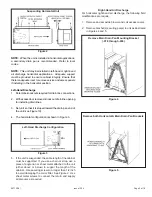

7. Install a 2” trap in the primary drain lines as close to the

unit as practical (see figure 9). Make sure the top of the

trap is below the connection to the drain pan to allow

complete drainage of the pan.

NOTE:

Horizontal runs must have an anti-siphon air vent

(standpipe) installed ahead of the horizontal run

(See

F

igure

9).

An extremely long horizontal run may require an

oversized drain line to eliminate air trapping.

NOTE:

Do not operate air handler without a drain trap.

The condensate drain is on the negative pressure side of

the blower; therefore, air being pulled through the

condensate line will prevent positive drainage without a

proper trap.

8. Route the drain line to the outside or to an appropriate

drain. Drain lines must be installed so they do not block

service access to the front of the air handler. A 24”

clearance is required for filter, coil, or blower removal

and service access.

NOTE:

Check local codes before connecting the drain line

to an existing drainage system.

Insulate the drain lines

where sweating could cause water damage.

TEST CONDENSATE DRAIN

Test the drain pan and drain line after installation:

1. Pour several quarts of water into drain pan, enough to

fill drain trap and line.

2. Check to make sure the drain pan is draining completely,

no leaks are found in drain line fittings, and water is

draining from the end of the primary drain line.

3. Correct any leaks found.

Duct System and Filters

DUCT SYSTEM

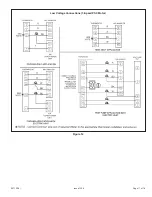

The air handler is provided with flanges for the connection

of the plenum and ducts. The air handler is equipped with

flanges that can form a filter rack for the installation of the

air filter, or the filter may be installed as part of the return

air duct system.

A field-fabricated secondary drain pan, with a drain

pipe to the outside of the building, is required in all

installations over a finished living space or in any area

that may be damaged by overflow from the main drain

pan. In some localities, local codes may require a

secondary drain pan for any horizontal installation.

IMPORTANT