507789-01

Issue 2007

Page 5 of 24

finished enclosure. Knockouts are provided for electrical

wiring entrance.

For ease in installation, it is best to make any necessary

coil configuration changes before setting air handler in

place.

Refrigerant Metering Device

BCE5V

units are equipped with a factory-installed check/

expansion valve.

HORIZONTAL DRAIN PAN

(MUST BE REMOVED)

UP-FLOW /

DOWN-FLOW

DRAIN PAN

Figure 1.

Upflow Configuration

Upflow Application

1. The air handler must be supported on the bottom only

and set on solid floor or field-supplied support frame.

Securely attach the air handler to the floor or support

frame.

2.

If installing a unit in an upflow application, remove the

horizontal drain pan.

NOTE:

The horizontal drain pan is not required in

upflow air discharge installations; its removal provides

the best efficiency and air flow.

3. Place the unit in the desired location and slope unit.

Connect return and supply air plenums as required

using sheet metal screws.

4. Install units that have no return air plenum on a stand

that is at least 14” from the floor. This will allow proper

air return.

Horizontal Applications

When removing the coil, there is a possibility of danger

of equipment damage and personal injury. Be careful

when removing the coil assembly from a unit installed

in right- or left-hand applications. The coil may tip into

the drain pan once it is clear of the cabinet. Support the

coil when removing it..

IMPORTANT

NOTE:

When the unit is installed in horizontal applications,

a secondary drain pan is recommended. Refer to local

codes.

NOTE:

This unit may be installed in left-hand or right-hand

air discharge horizontal applications. Adequate support

must be provided to ensure cabinet integrity. Ensure that

there is adequate room to remove service and access

panels if installing in the horizontal position.

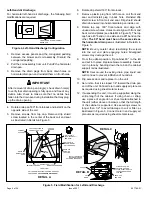

Right-Hand Discharge

1.

Determine which plugs are required for drain line

connections.

2. With access door removed, remove drain line plugs to

install drain lines.

3.

Set unit so that it is sloped toward the upflow drain pan

end of the unit and level from front to back of unit (see

4.

The horizontal configuration is shown in Figure 2.

Drains

AIR FLOW

PLUGS

RIGHT

‐

HAND DRAINS

Drip

Shield

Figure 2.

Right-Hand Discharge Configuration

5. If the unit is suspended, the entire length of the cabinet

must be supported. If you use a chain or strap, use a

piece of angle iron or sheet metal attached to the unit

(either above or below) to support the length of the

cabinet. Use securing screws no longer than 1/2 inch

to avoid damaging the coil or filter. See Figure 3. Use

sheet metal screws to connect the return and supply

air plenums as required.

FRONT

W

E

I

V

D

N

E

W

E

I

V

ANGLE IRON OR SHEET

METAL

E

ANCE 4 IN. (102 MM)

MAXIMUM 1/2"

LONG SCREW

AIR FLOW

Figure 3. Suspending Horizontal Unit