507789-01

Issue 2007

Page 7 of 24

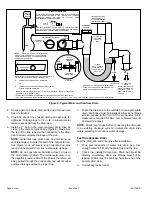

Condensate Drain

On units of this type, where the blower “draws” rather

than “blows” air through the coil, traps must be installed

in the condensate drain lines (primary and auxiliary,

if used). Traps prevent the blower from drawing air

through the drain lines into the air supply.

IMPORTANT

A field-fabricated secondary drain pan, with a drain

pipe to the outside of the building, is required in all

installations over a finished living space or in any area

that may be damaged by overflow from the main drain

pan. In some localities, local codes may require a

secondary drain pan for any horizontal installation.

IMPORTANT

Sloping The Unit

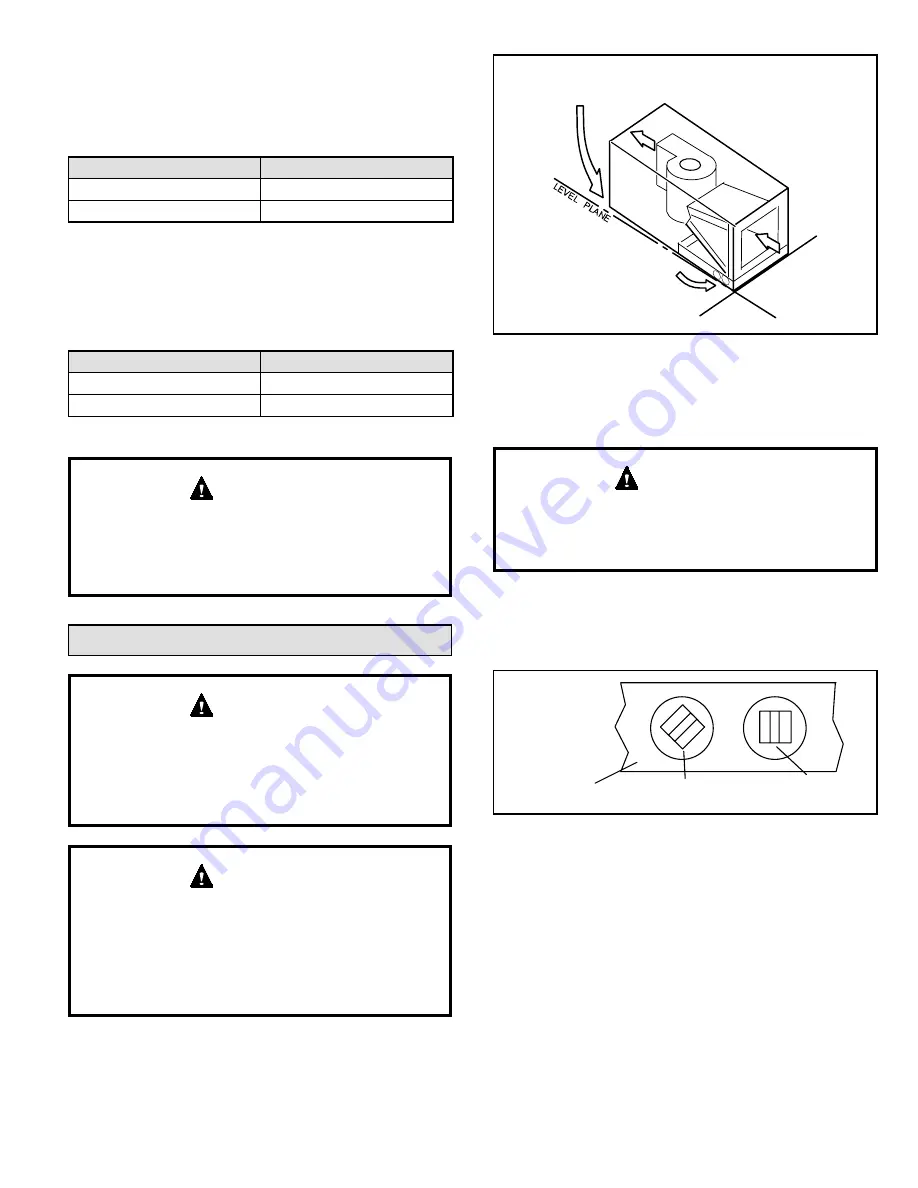

Make sure the unit is sloped (similar to the slope shown

in Figure 6) so that the drain pan will empty completely

without water standing in the pan.

THIS CORNER SHOULD BE 5/8" (+/- 1/8") HIGHER

THAN DRAIN CORNER

DRAIN CORNER

LE

VE

L P

LA

NE

Figure 6. Sloping the Unit for Proper Drainage

Install Condensate Drain

The air handler is provided with 3/4” NPT condensate drain

connections.

On some pans, the primary and secondary drain holes

have knockouts.

Confirm primary and secondary drains are open.

IMPORTANT

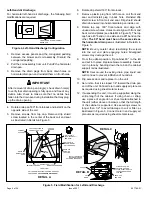

1. BCE5V

units are equipped with a drain pan, which

includes green (main drain) and red (secondary drain)

plugs. Unscrew the plugs to remove them before

inserting condensate drain fittings.

DRAIN PAN

RED SECONDARY

DRAIN PLUG

UNSCREW PLUGS

AND CONNECT

PROPERLY SIZED

FIELD-PROVIDED

FITTINGS AND

DRAIN LINES.

GREEN MAIN

DRAIN PLUG

Figure 7. Drain Line Connections

2.

Install properly sized, field-provided connection fittings

and connect primary drain line to the main drain pan

connection.

NOTE:

When installing drain line connection fittings

to the drain pan, hand tighten the fitting and use a

thread sealant. Over-tightening the fittings can split

connections on the drain pan.

3. If the secondary drain line is to be used, remove the

plug or the knockout and route the drain line so that

water draining from the outlet will be easily noticed

by the homeowner. Refer to local codes for drain trap

requirements on the secondary drain line.

Downflow Application

If downflow application is required, separately order a

downflow conversion kit and install per kit instructions.

See Table 1 for kit information. Also use metal or class I

supply and return air plenums.

Model

Kit Number

018, 024, 030

Y9658

036, 042, 048, 060

Y9659

Table 1.

Downflow Conversion Kits

Units installed on combustible floors in the downflow

position with electric heat require a downflow combustible

flooring base. See Table 2 for kit information. Install per kit

instructions.

Model

Kit Number

018, 024, 030

12W95

036, 042, 048, 060

12W96

Table 2.

Downflow Combustible Floor Base Kits

If electric heat section with circuit breakers (ECBA25) is

installed in a BCE5V

unit in a downflow application, the

circuit breakers must be rotated 180° to the UP position.

See ECBA25 installation instructions for more details.

IMPORTANT