507838-01

Issue 1813

Page 9 of 19

BCE7E

Filter Size – In. (mm)

-018, -024, -030, -036

20” x 20” (508mm x 508mm)

-042, -048, -060

20” x 24” (508mm x 610mm)

Table 3. Filter Dimensions

Sealing the Unit

There must be an airtight seal between the bottom of

the air handler and the return air plenum. Use fiberglass

sealing strips, caulking, or equivalent sealing method

between the plenum and the air handler cabinet to

ensure a tight seal. Return air must not be drawn from a

room where this air handler or any gas-fueled appliance

(i.e., water heater), or carbon monoxide-producing

device (i.e., wood fireplace) is installed.

WARNING

Seal the unit so that warm air is not allowed into the cabinet.

Warm air introduces moisture, which results in water blow-

off problems. This is especially important when the unit is

installed in an unconditioned area.

Make sure the liquid line and suction line entry points are

sealed with either the provided flexible elastomeric thermal

insulation, or field provided material (e.g. Armaflex,

Permagum or equivalent). Any of the previously mentioned

materials may be used to seal around the main and

auxiliary drains, and around open areas of electrical inlets.

Measuring Static Pressure

1. Measure tap locations as shown in Figure 9.

MANOMETER

SUPPLY

RETURN

UNIT SHOWN IN

HORIZONTAL DISCHARGE LEFT POSITION

Figure 9. Static Pressure Test

2.

Punch a 1/4ʺ (6mm) diameter hole in supply and return

air plenums. Insert manometer hose flush with inside

edge of hole or insulation. Seal around the hose with

Permagum. Connect the zero end of the manometer to

the discharge (supply) side of the system. On ducted

systems, connect the other end of manometer to the

return duct as above. For systems with non-ducted

returns, leave the other end of the manometer open to

the atmosphere.

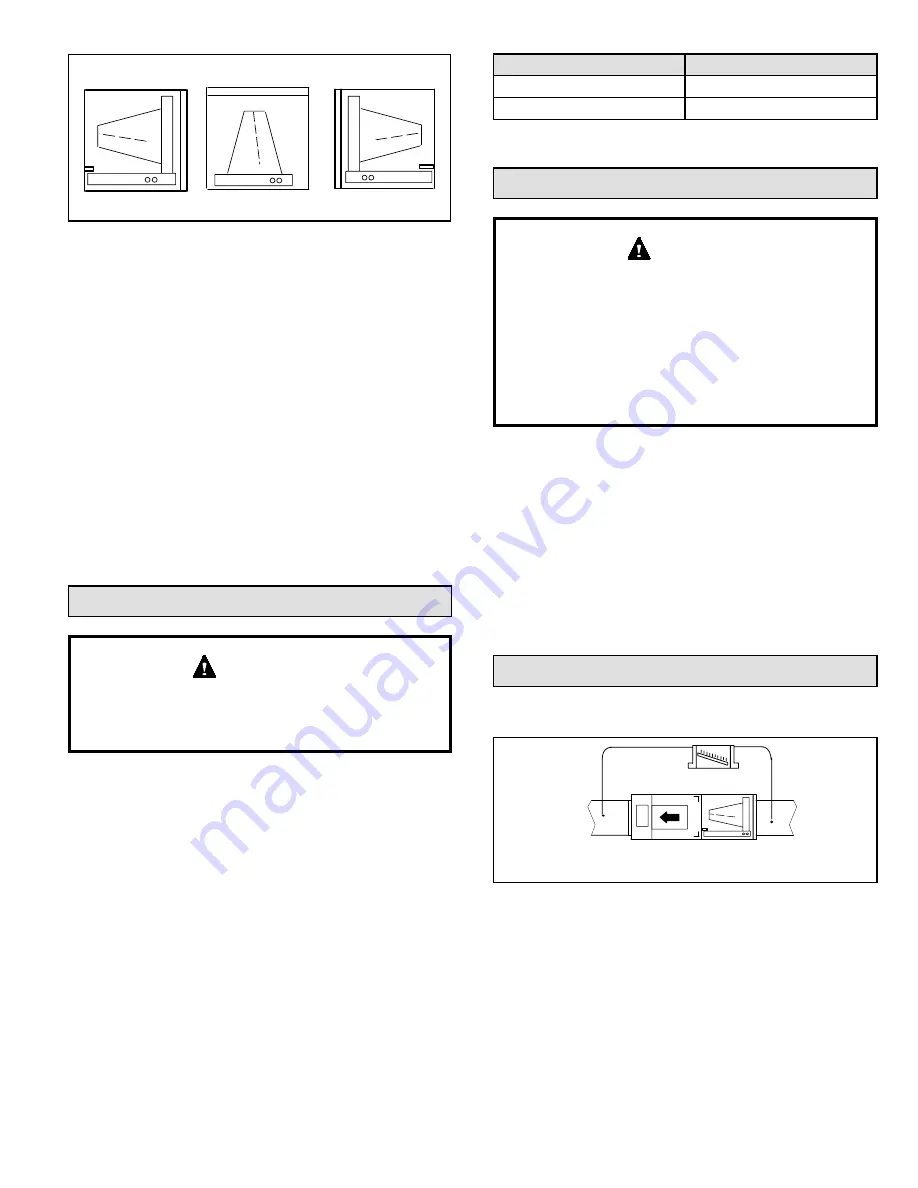

LEFT-HAND AIR

DISCHARGE

MAIN DRAIN ON

RIGHT

OVERFLOW

DRAIN ON LEFT

UP-FLOW OR

DOWN-FLOW

RIGHT-HAND AIR

DISCHARGE

Figure 8.

Main and Overflow Drain Locations Based

on Coil Orientation

Best Practices

The following best practices are recommended for the

condensate removal process:

•

Main and overflow drain lines should NOT be smaller

than both drain connections at drain pan.

•

Overflow drain line should run to an area where

homeowner will notice drainage.

•

It is recommended that the overflow drain line be

vented and a trap installed. Refer to local codes.

•

Condensate drain lines must be configured or provided

with a cleanout to permit the clearing of blockages and

for maintenance without requiring the drain line to be

cut.

Inspecting and Replacing Filters

Filter access panel must be in place during unit

operation. Excessive warm air entering the unit may

result in water blow-off problems.

IMPORTANT

Filters may be duct-mounted or installed in the cabinet. A

filter is installed at the factory. Note that filter access door

fits over access panel. Air will leak if the access panel is

placed over the filter door.

Filters should be inspected monthly and must be cleaned or

replaced when dirty to assure proper air handler operation.

Reusable filters supplied with some units can be washed

with water and mild detergent. Some units are equipped

with standard throw-away type filters which should be

replaced when dirty.

To replace filter:

1.

Loosen the thumbscrews holding the filter panel in

place. Remove the dirty filter.

2.

Insert new filter and replace panel.