# 47904K005

Page 13

these areas, moisture in the flue gases may condense and

freeze on the air intake if this height is reduced. In milder

climates, this may be reduced to a minimum of 6". Height

may be increased as needed provided the total length of

pipe to furnace is not exceeded.

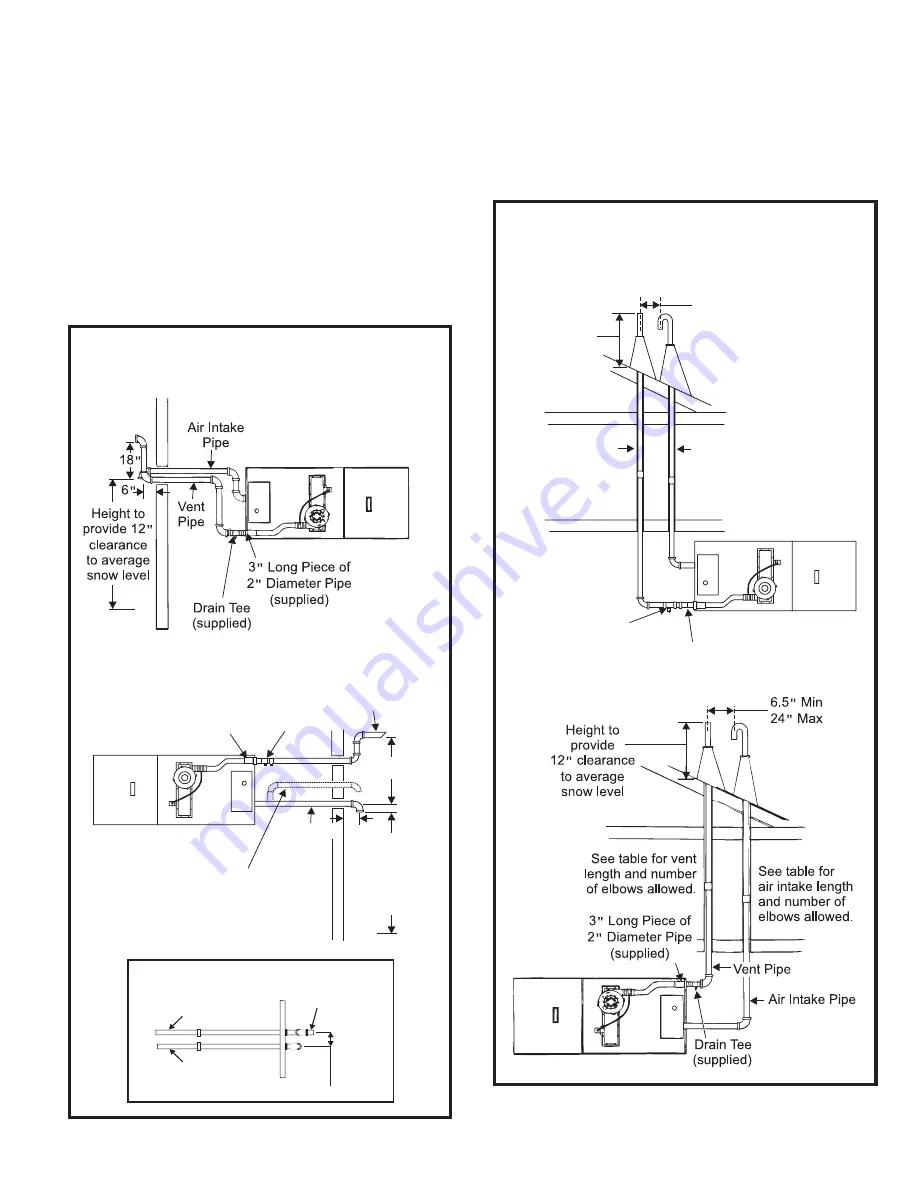

For horizontal venting, refer to Figure 11. For vertical

venting, refer to Figure 12. It is permissible to run the vent

vertically through the roof and terminate it as shown in

Figure 12, and to run the combustion air intake pipe

horizontally through a side wall and terminate as shown in

Figure 11. The vent pipe on horizontal runs must slope

upward, away from the furnace, at a minimum pitch of 1/4"

per foot of run, to prevent accumulation of condensate.

Do not cement air intake into the connector on burner

box. Use high temperature RTV silicone sealant so

intake pipe can be removed if service is required.

In horizontal venting applications, the vent and air

intake pipe must be installed on the same side of the

house within the parameters shown in Figure 11.

Horizontal Direct Vent –

Horizontal Venting

Figure 11

3 Long Piece of

2 Diameter Pipe

(supplied)

"

"

18

"

6

"

Drain Tee

(supplied)

Height to

provide 12

clearance

to average

snow level

"

Vent

Pipe

Air Intake

Pipe

Intake may be raised as

shown to obtain minimum snow

clearance requirements.

Airflow Left to Right

Airflow Right to Left

THIS PIECE

IS OPTIONAL.

INTAKE PIPE

FLUE PIPE

3” MIN. - 48” MAX.

Overhead View

Figure 12

Horizontal Direct Vent –

Vertical Venting

Height to

provide 12

clearance

to average

snow level

"

Drain Tee

(supplied)

3 Long Piece of 2 Diameter Pipe

(supplied)

"

"

6.5 Min

24 Max

"

"

Vent Pipe

Air Intake Pipe

See table for air intake

length and number of

elbows allowed.

See table for vent

length and number

of elbows allowed.

Airflow Right to Left

Airflow Left to Right