10

Pneumatic Piping for Air Operated Humidifier–AM Models

STEP 9A: Install Pneumatic Piping

in accordance with Fig. 10-1 or

engineer’s layout.

a. Control Air Supply. Unless

otherwise specified, air supply for

Armstrong Humidifiers should be 20

psig maximum. This air must be

clean and dry.

b. Air Piping.

1

¼

4

" plastic tubing or

equivalent is recommended for all

air connections.

Note:

When a pilot positioner is

furnished, it should be hooked up as

shown in Fig. 10-3.

STEP 10A: Install and Connect

Humidity Controller

as specified by

engineer in accordance with

manufacturer’s instructions. If location

is not specified it may be installed in

the area controlled or in either the

return air or exhaust air ducts.

Auxiliary Controls

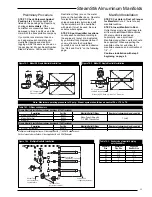

Hi-Limit Duct Humidity Controller.

A

high limit humidistat is recommended

in the duct at least 10 feet

downstream from the humidifier to

override the controlling humidistat.

This high-limit humidistat automatically

prevents local saturation at the point of

steam introduction. It also prevents

overloading the duct with vapor in the

event of failure of air conditioning

system components, incorrect control

settings or tampering. See Fig. 10-1.

Interlocks for Shutdowns.

Humidifiers should be interlocked with

fans for shutdown on power failure or

other system trouble. Interlock should

be such that the valve will go to the

closed position on a system shutdown

rather than be locked in its position at

time of shutdown. See Figure 10-2.

Temperature Switch for Automatic

Warm Up.

For systems that may be

started and stopped, such as in

laboratories or in operations which

shut down each weekend, a

temperature switch is recommended

on the condensate outlet from the

humidifier. Your Armstrong

Representative can supply an

immersion type unit that will

automatically keep valves closed

during warm up period after shutdown.

This will avoid the discharge of

condensate that can occur if steam is

admitted to cold humidifier piping

when the humidifier valve is open See

Fig. 10-1.

Figure 10-1. Standard compressed air hook-up for all pneumatically

operated humidifiers. Pneumatic temperature switch shown.

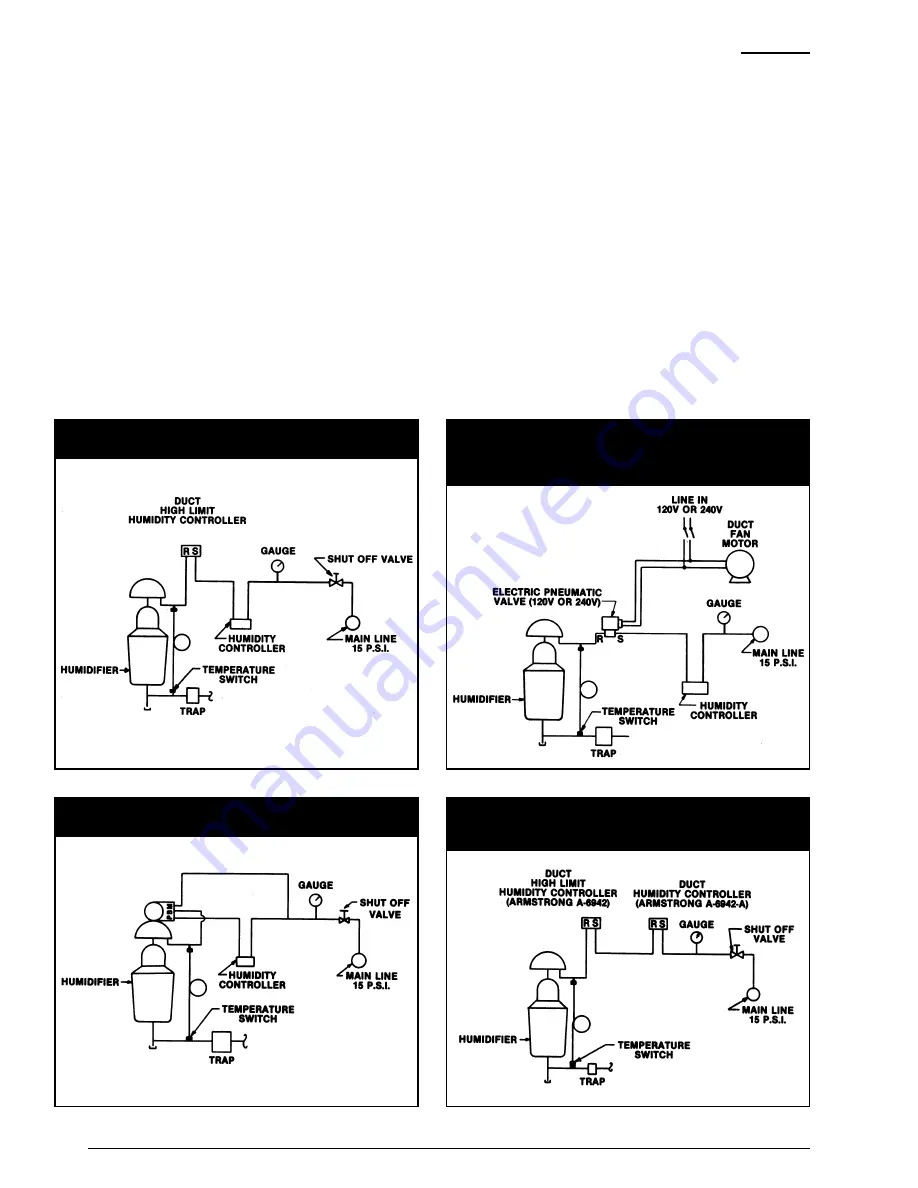

Figure 10-3. Compressed air hook-up for humidifiers utilizing a

Honeywell MP953-F pneumatic operator with pilot positioner.

Figure 10-4. Compressed air hook-up for humidifiers utilizing two

Armstrong Duct Humidity Controllers, one as the humidity controller,

the other as a high limit controller.

Figure 10-2. Compressed air hook-up for air operated humidifiers

incorporating safety interlock for shutdown in the event of power failure

to fan and an electric temperature switch to prevent water discharge on

start-up when humidifier piping is cold.