11

Wiring for Electrically Operated Humidifiers–EM Models

EM Models

STEP 9E (EM): Make Electrical

Connections

as recommended by the

manufacturers of the operators and

controls.

“EM” Series electric motor operated

humidifiers are furnished with a choice

of Honeywell M9182A operators,

Barber-Coleman MP361 or MP461, or

Belimo AF24SR or NVF24 electric

motorized operators. These operators

may be controlled by compatible

humidity controllers or electronic

humidity panels.

For all EM operators, mount

operator so that the motor shaft is

horizontal to the floor.

STEP 10E (EM): Install Temperature

Switch.

Remove cover of switch for

access to adjustable mounting strap.

Strap the switch to the humidifier drain

line piping just ahead of the steam

trap.

Solenoid Models

(DSA Models)

STEP 9E: Make Electrical

Connections

as diagrammed in Fig.

11-2. Be sure wiring is adequate for

the requirements of the system. Check

voltage ratings on operator nameplate.

STEP 10E: Install and Wire Humidity

Controller

as specified by the design

engineer and in accordance with

manufacturer’s instructions. If location

is not specified, the controller may be

installed in area controlled or in either

the return air or exhaust air ducts.

STEP 11E: Install Temperature

Switch.

Remove cover of switch for

access to adjustable mounting strap.

Strap the switch to the humidifier drain

line just ahead of the steam trap.

STEP 12E: Check Out Solenoid

Valve.

After making electrical

connections, move the humidity

setting indicator of the humidistat back

and forth past the point corresponding

with the actual room humidity. You

should be able to hear the solenoid

valve click open and click shut. For

test purposes a jumper will have to be

used on the temperature switch

connections since the function of this

switch is to prevent energizing the

solenoid until the humidifier reaches

steam temperature.

Auxiliary Controls

for All Models

Hi-Limit Duct Humidity Controller.

An enclosed switch type high limit

humidistat is recommended in the duct

at least 10 feet downstream from the

humidifier to override the controlling

humidistat. It is particularly

recommended with on/off models. This

high limit humidistat automatically

prevents local saturation at the point of

steam introduction. It also prevents

overloading the duct with vapor in the

event of failure of air conditioning

system components, incorrect control

settings or tampering.

Interlocks for Shudowns.

Humidifiers should be interlocked with

fans for shutdown on power failure or

other system trouble. Interlock should

be such that valve will go to the closed

position on a system shutdown rather

than be locked in its position at time of

shutdown.

Temperature Switch for Automatic

Warm Up.

This is a strap-on type and

is connected to the interlock system to

automatically keep valves closed

during warm up period after shutdown.

This will avoid the discharge of

condensate that can occur if steam is

admitted to cold humidifier piping

when the humidifier valve is open.

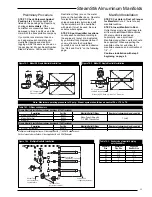

HC-201 High Limit Duct

Humidity Controller

(when used)

Temp. Switch

120 V. or 240 V.

24 V.

Transformer

M9182A (Series 90)

Motorized Operator

O

T

T

B

B

B

R

R

R

W

W

H915A (Series 90)

Humidity Controller

If High Limit Not Used

Wire R Directly to R

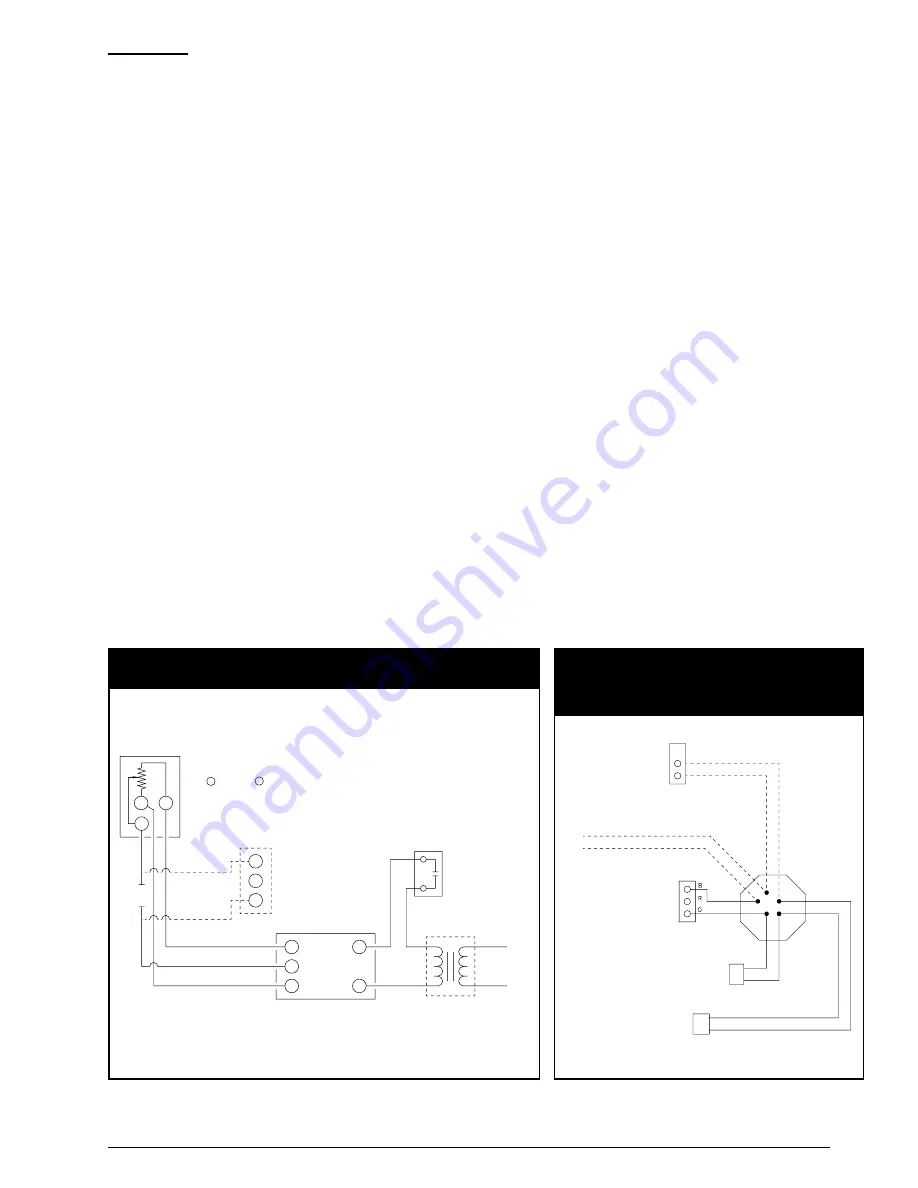

HC-201 High Limit Duct Humidity

Controller (Set at 90%)

(Used enclosed type switch)

Temp.

Switch

Solenoid

Interlock with Fan System

120 V. or 240 V. Single Phase

HC-101 Humidity Controller

Figure 11-1. Wiring diagram for HEM Series humidifiers using Honeywell M9182A

operator and H915A potentiometer controller.

Figure 11-2. Wiring diagram for 120v or 240v Solenoid

model humidifier. Wiring for auxiliary high limit duct

humidity controller and interlock for system shutdown is

shown in dotted lines.

NOTE: For wiring data covering Barber-Coleman operators, contact the factory or your Barber-Coleman dealer.